Descaling mechanism and descaling device

A technology of clamping mechanism and transmission shaft, which is applied in the direction of fish cleaning/descaling, etc., can solve the problems of difficult processing and limited applicability of descaling discs, and achieve the effect of easy processing, low cost and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

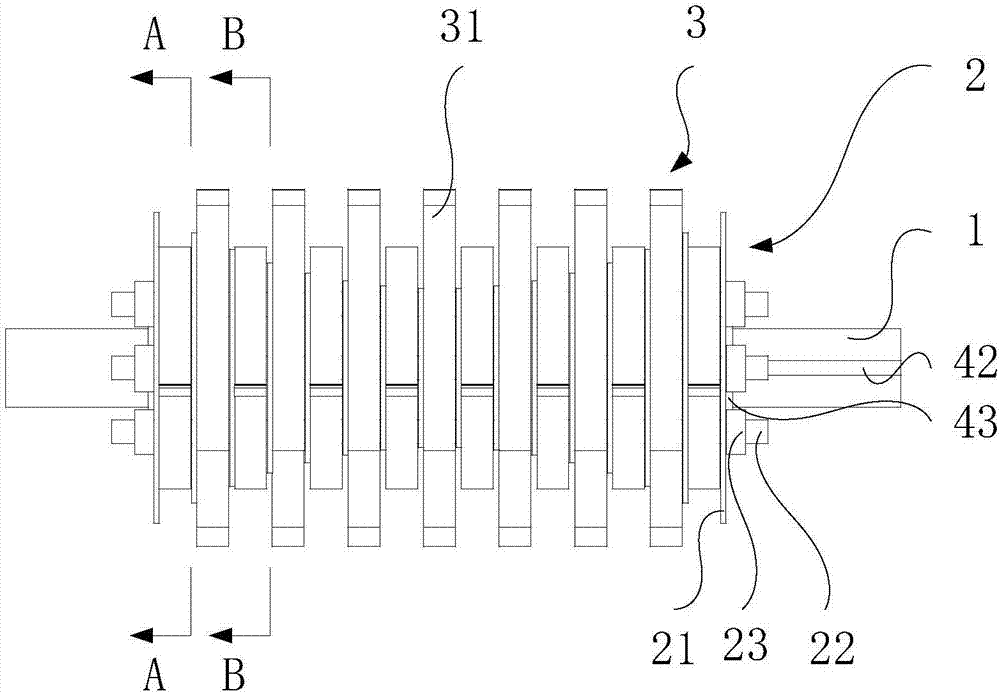

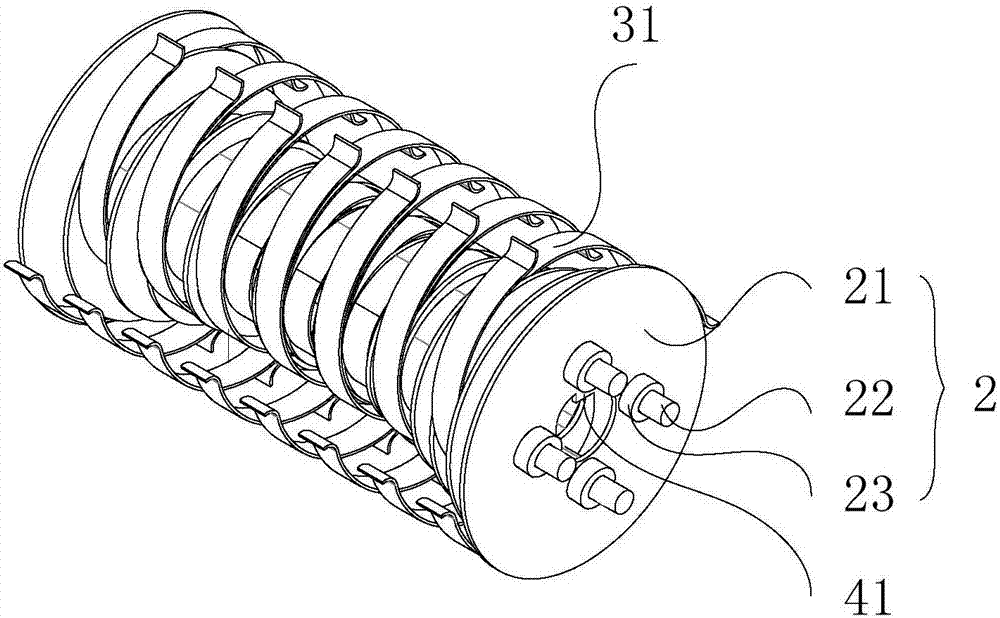

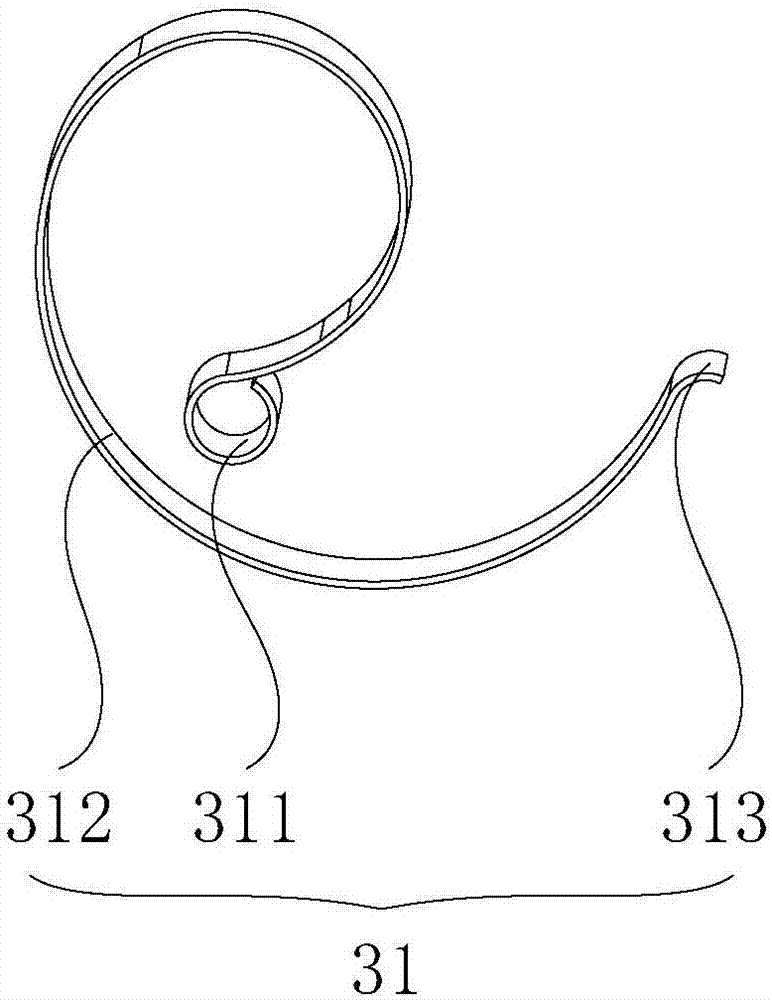

[0042] The purpose of this embodiment is to provide a descaling mechanism, such as figure 1 with figure 2 As shown, it includes a transmission shaft 1, a tool mounting assembly 2 and a tool assembly 3, wherein: the tool mounting assembly 2 is sleeved on the transmission shaft 1 through a clamping mechanism 4; the tool assembly 3 is connected to the tool mounting assembly 2, and the tool assembly 3 includes Multiple pairs of blades 31, multiple pairs of blades 31 are spirally arranged in sequence along the axial direction of the transmission shaft 1, and the blades 31 surround the tool installation assembly 2 in a sheet-like spiral structure, so that the blades 31 can be elastic along the radial direction of the transmission shaft 1 Deformation, one end of the blade 31 is connected with the cutter mounting assembly 2, and the end of the blade 31 is curved for descaling.

[0043] In the descaling mechanism provided in this embodiment, the transmission shaft is used to drive th...

Embodiment 2

[0064] The purpose of this embodiment is to provide a descaling device. The descaling device provided in the second embodiment includes the descaling mechanism provided in the first embodiment above.

[0065] Compared with the prior art, the descaling equipment provided by this embodiment has wider applicability, and can descale both large and small fish. After the treatment, it can ensure that the fish meat is not damaged, and the user experience is better. , and low cost, long service life, can bring greater economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com