Precise omega-type full lock positioning method and locator for reinforcement of flood control wall

A positioning method and flood control wall technology, applied in dikes, coastline protection, dams, etc., can solve problems affecting construction accuracy, rough construction quality, and unsatisfactory engineering quality, and achieve the effect of providing work efficiency, low cost, and not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

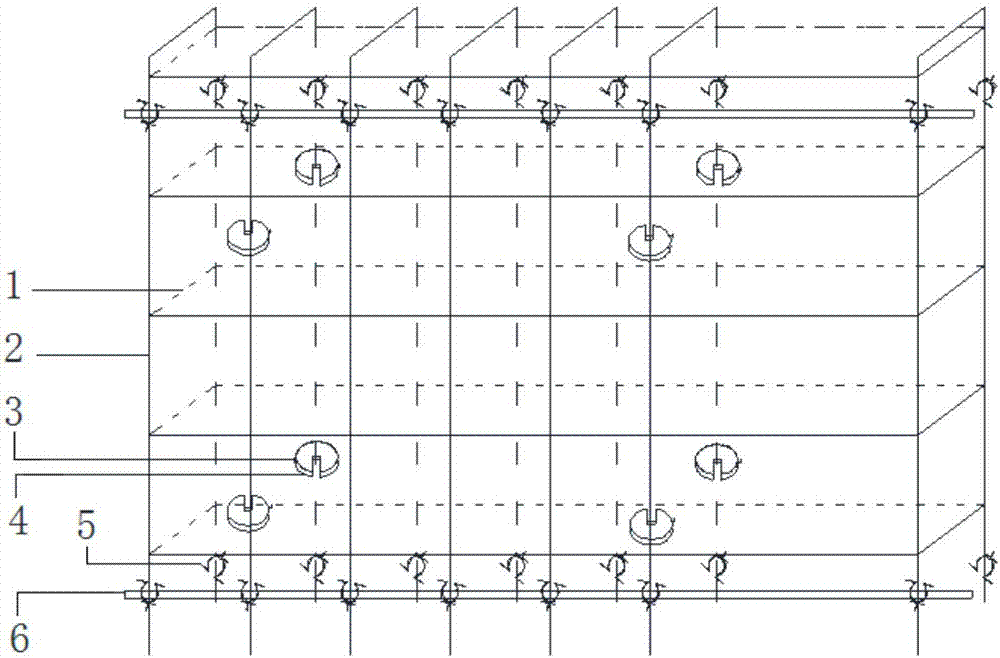

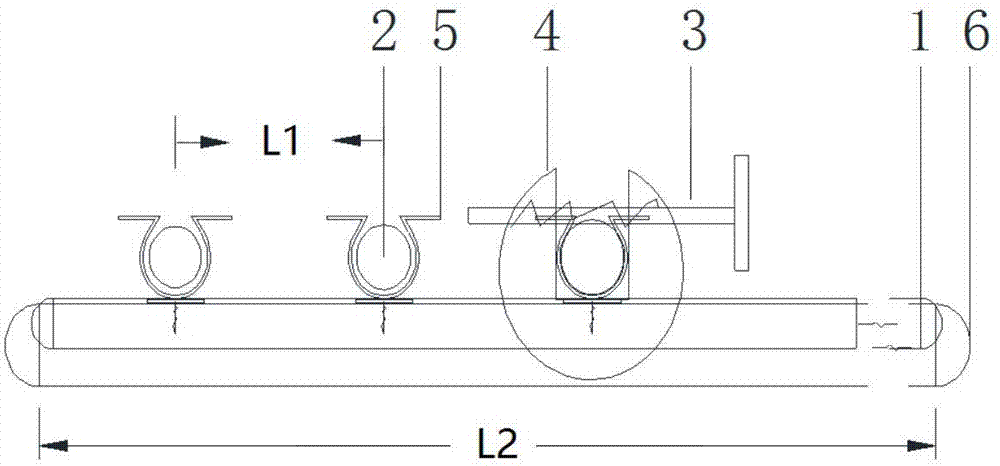

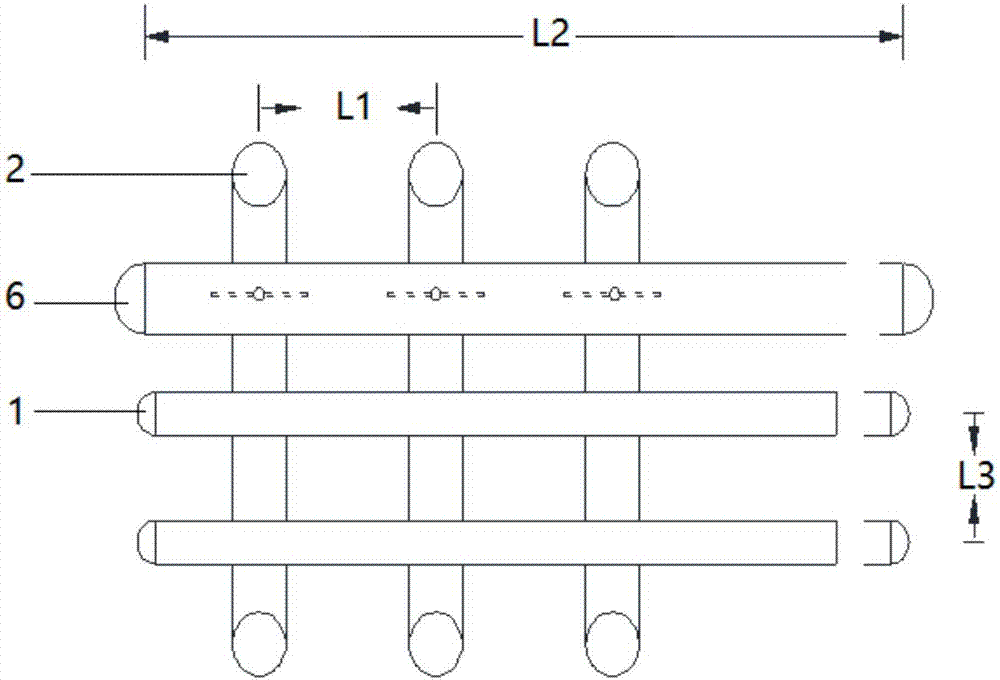

[0034] Embodiment 1: as attached figure 1 As shown, the construction includes the following steps: (1) Prepare the Ω lock 5 and the disk slotted weight pad 4 according to the design size; (2) Determine the location of the main reinforcement 2 of the flood control wall; (3) Use the Ω lock 5. Lock the main ribs 2 at the inner and outer sides; (4) The main ribs 2 at both ends of the inner and outer sides are locked with the Ω lock 5 connected to the galvanized steel pipe 6 to form a fixed frame. (5) After the main reinforcement 2 is placed, measure the control line of the distribution reinforcement 1 with a tape measure and draw it with chalk; (6) Bind the distribution reinforcement 1 to the main reinforcement 2 in sequence; ( 7) Buckle the prefabricated disk slotted weight pad 4 at the designated position of the main reinforcement 2; (8) Take out the Ω lock 5 with the galvanized steel pipe 6 from the main reinforcement 2; (9) Check the positioning of the reinforcement and the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com