A water pump high-pressure pressurizing device

A technology of a pressurizing device and a pumping pump, which is applied to the components, pump components, pump control and other directions of the pumping device for elastic fluids, can solve the problems of high cost, high power consumption, and is not environmentally friendly, and achieves low cost, The effect of improving the utilization rate of water energy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

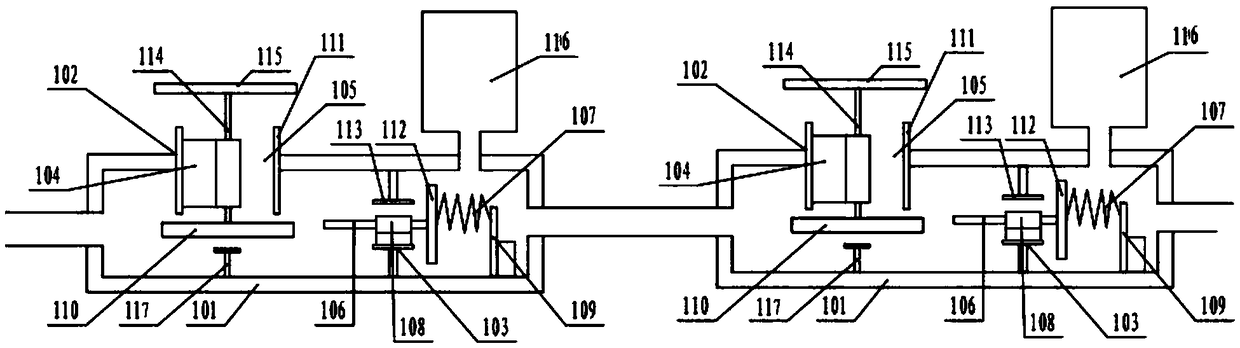

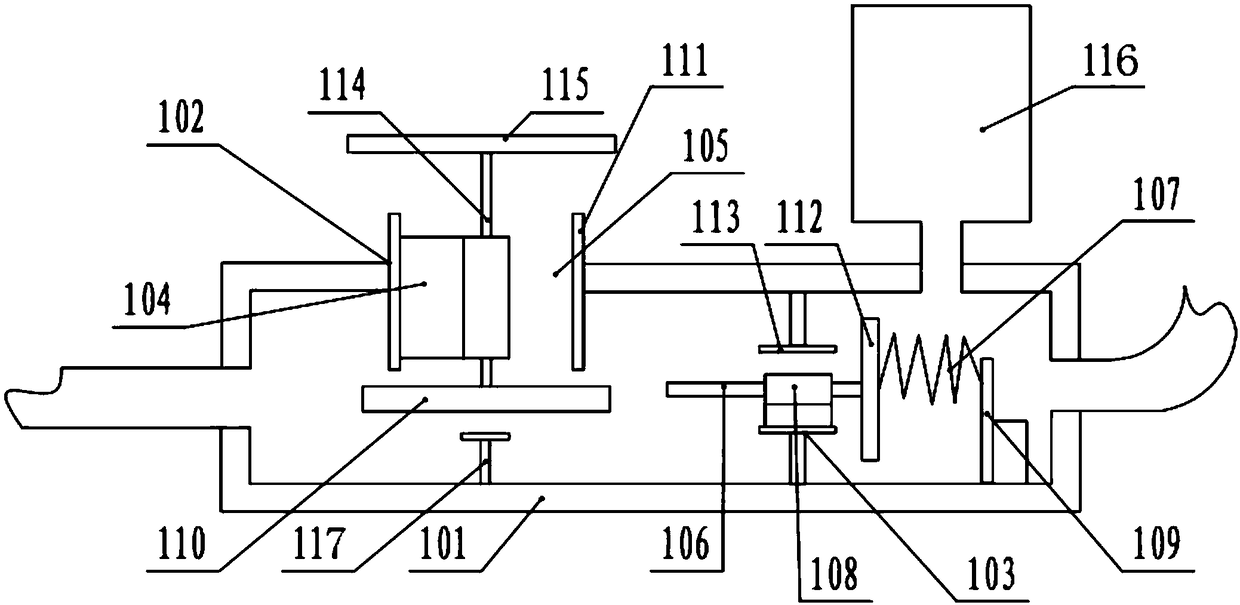

[0021] Embodiment 1: as Figure 1~Figure 8 As shown, a high-pressure pressurization device for a water pump includes at least two pressurization devices 1 connected in series, the water inlet of the first pressurization device 1 is connected to a high-level water source, and the water outlet is connected to the water inlet of the next-stage pressurization device 1 , the water inlet of the pressurizing device 1 adjacent to the previous stage is larger than the water inlet of the pressurizing device 1 of the subsequent stage.

[0022] Preferably, the above-mentioned pressurizing device 1 includes a cavity 101, the side wall of the water inlet end of the cavity 101 is provided with a valve one 102, and the water outlet end is provided with a valve two 103, the valve one 102 includes a valve plate 110 and a valve cavity 111, the valve plate The upper end surface of a 110 is connected with a valve shaft 114, and the valve shaft 114 passes through the valve cavity 111 and is connect...

Embodiment 2

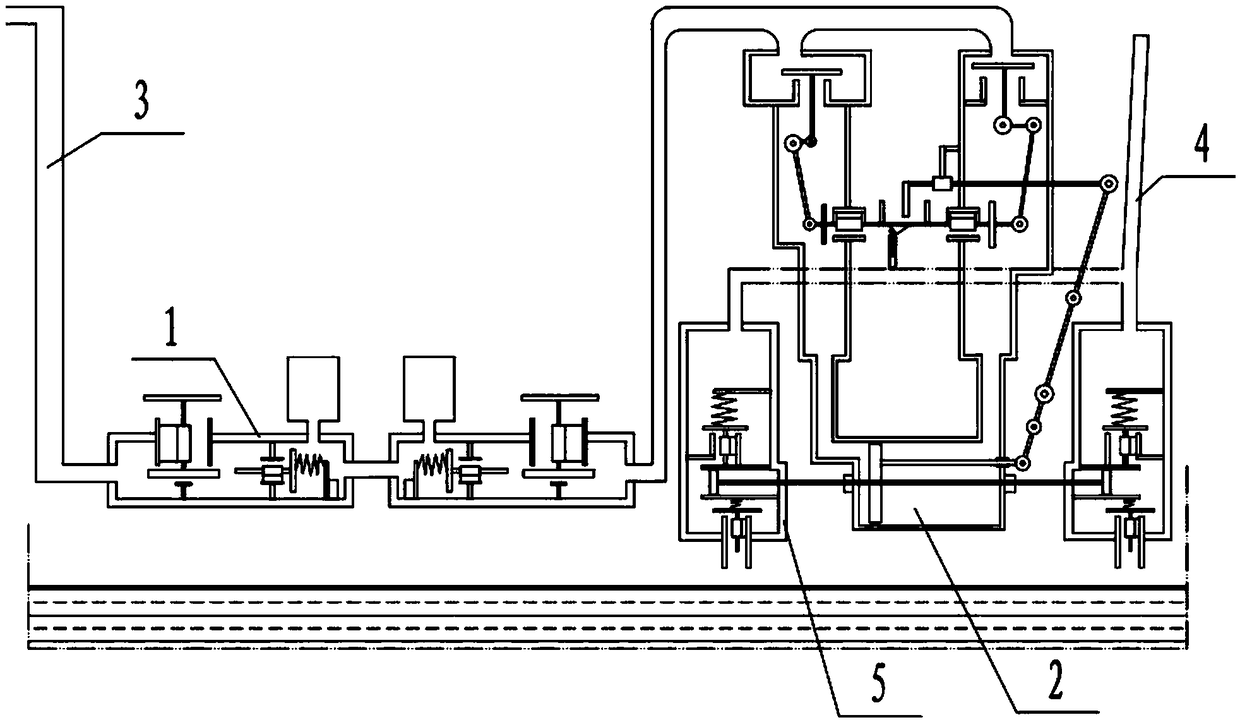

[0027] Embodiment 2: as Figure 1~Figure 8 As shown, the above-mentioned pressurizing device 1 is used for a pressurized water pump, including at least one pressurized device 1, a plunger cylinder 2 and a water pump 5, and the water inlet pipe 3 of each pressurized device 1 is connected to the high-level water source port. The outlet pipe 4 is connected to the water pump 5, the push rod 202 of the plunger cylinder 2 is connected to the piston 501 of the water pump 5, the water inlet of the water pump 5 is connected to the low water source port, and the water outlet is connected to the user water supply pipe.

[0028] Preferably, the plunger cylinder 2 includes a plunger 201 and a push rod 202, the plunger 201 is placed in the plunger chamber 203, the push rod 202 is fixedly connected to the plunger 201, and one end of the extension is connected to the piston 501, and the plunger chamber 203 are provided with water inlet and outlet 204 .

[0029] Preferably, the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com