Damping force-controllable dry friction damping bearing

A damping bearing and dry friction technology, applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of non-linear increase of oil film, unbalanced rotor system, poor stability, etc., and achieve vibration energy consumption, flexible steering, and bearing The effect of small external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below in conjunction with the accompanying drawings.

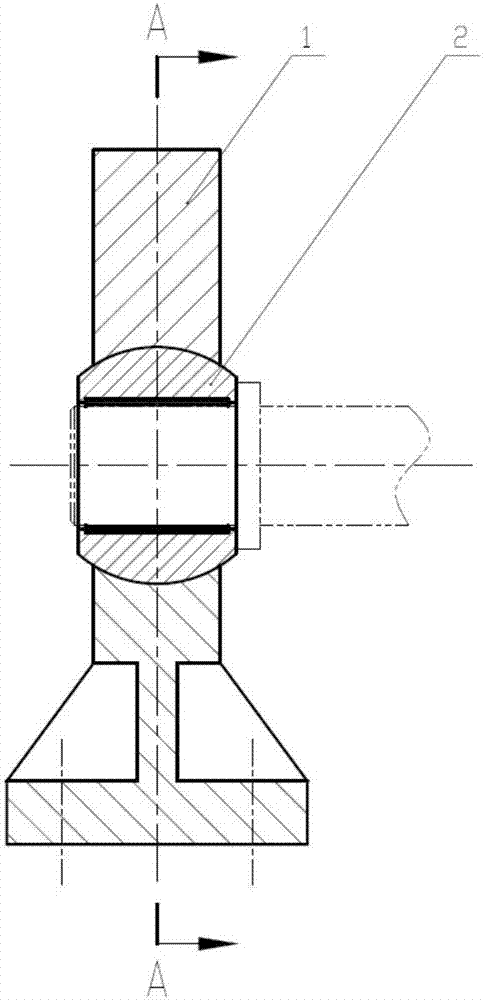

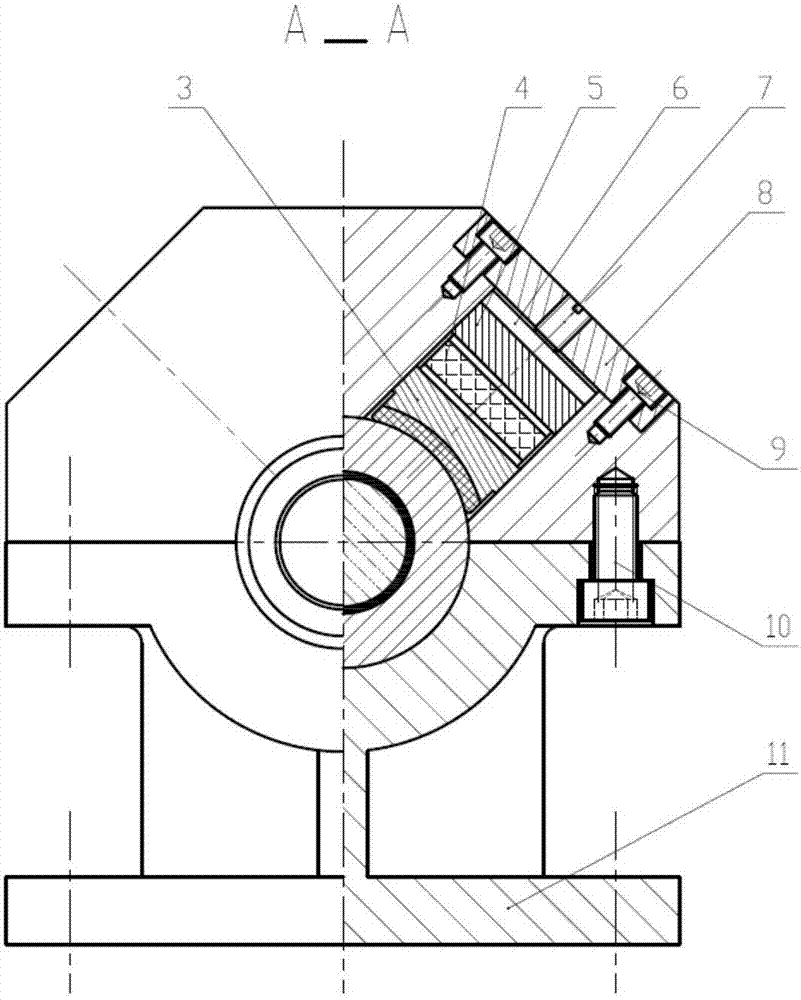

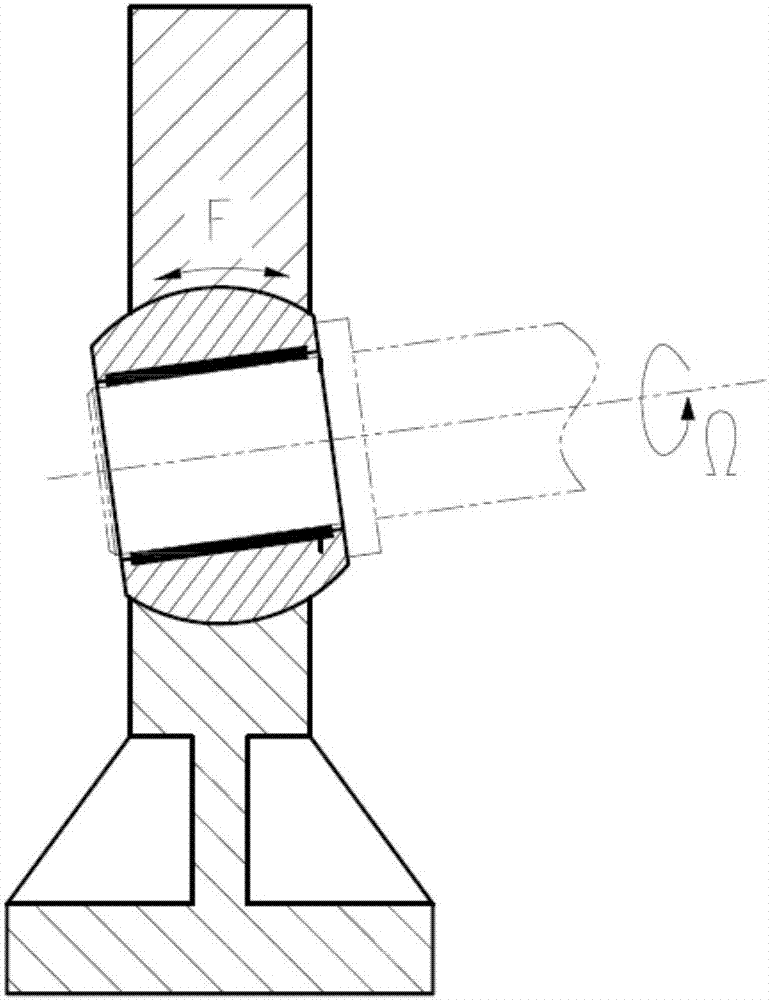

[0020] A dry friction damping bearing with controllable damping force, comprising: a bearing body and a bearing base 11, such as figure 1 shown. The bearing body includes: bearing cover 1, universal sliding bearing 2, and sliding assembly; the sliding assembly includes sliding head 3, piezoelectric ceramic assembly 4, force sensor 5, backing plate 6, preloading bolt 7 and side end cover 8, such as figure 2 shown.

[0021] The bearing body has two identical bearing caps 1 that match each other; the inside of the bearing cap 1 is hollow, and the hollow inner surface is an inner spherical surface; the hollow part of the bearing cap 1 is installed with a universal sliding bearing 2, and the outer The surface matches the hollow inner surface; the universal sliding bearing 2 has an inner shaft hole, and the inner shaft hole is embedded with a sliding bearing bush; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com