Frequency converter set and oil return control method and device

A frequency conversion unit and oil return control technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as cooling loss, reduce cooling loss and ensure the reliability of oil return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The oil return control method of the frequency conversion unit provided by the present invention will be described below in conjunction with the accompanying drawings.

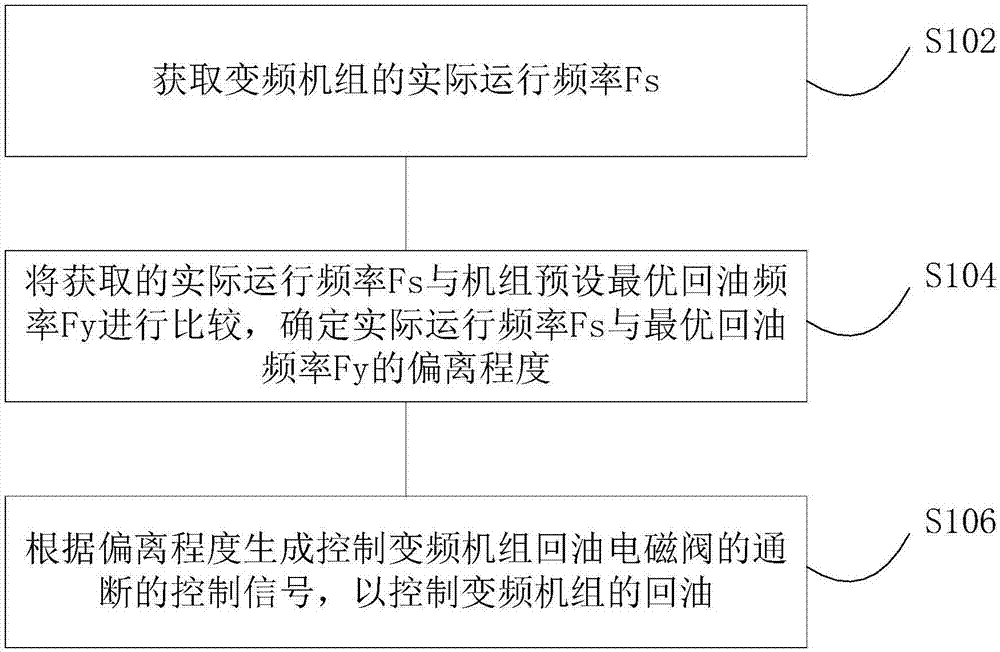

[0029] The oil return control method of frequency conversion unit provided by the present invention can be applied to frequency conversion unit equipment, such as: household frequency conversion air conditioners, frequency conversion air conditioners on shopping malls or ships, etc., can be implemented by installing software on the equipment or on the main controller of the unit It is realized by writing the corresponding control program above, such as figure 1 As shown, the oil return control method of the frequency conversion unit may include the following steps S102-S106:

[0030] S102, obtaining the actual operating frequency Fs of the frequency conversion unit;

[0031] S104, comparing the acquired actual operating frequency Fs with the preset optimal oil return frequency Fy of the unit, and deter...

Embodiment 2

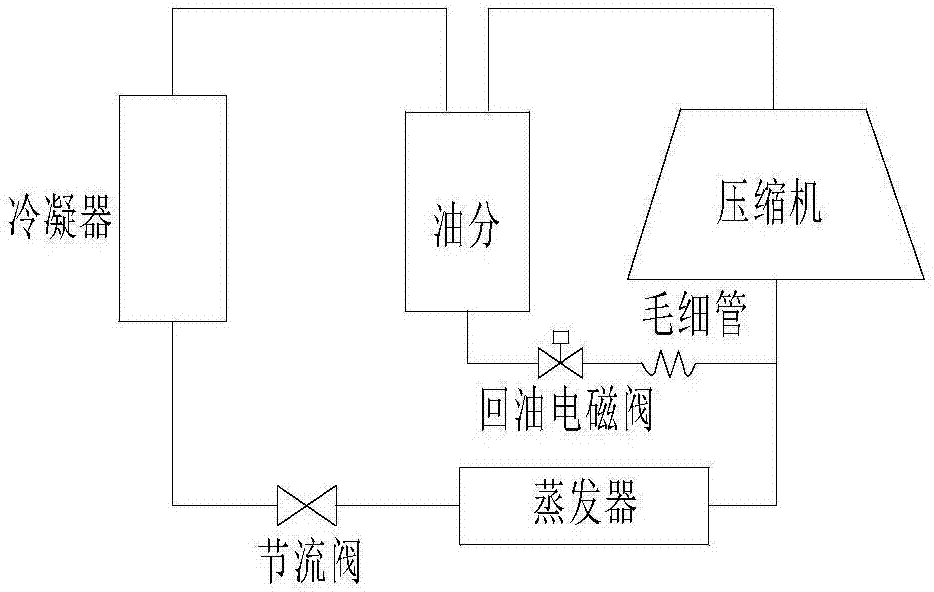

[0044] Based on the oil return control method of the frequency conversion unit provided in the above embodiment 1, the optional embodiment 2 of the present invention also provides a frequency conversion unit, specifically, figure 2 An optional schematic diagram showing the structure of the frequency conversion unit, such as figure 2 As shown, the frequency conversion unit includes:

[0045] A compressor, the compressor has an exhaust port and an air return port;

[0046] Oil separator (oil separation), the first interface of the oil separator is connected to the exhaust port of the compressor, and the second interface of the oil separator is connected to the air return port of the compressor;

[0047] a condenser, the first end of the condenser is connected to the third interface of the oil separator;

[0048] An evaporator, the first end of the evaporator is connected to the second end of the condenser, and the second end of the evaporator is connected to the air return p...

Embodiment 3

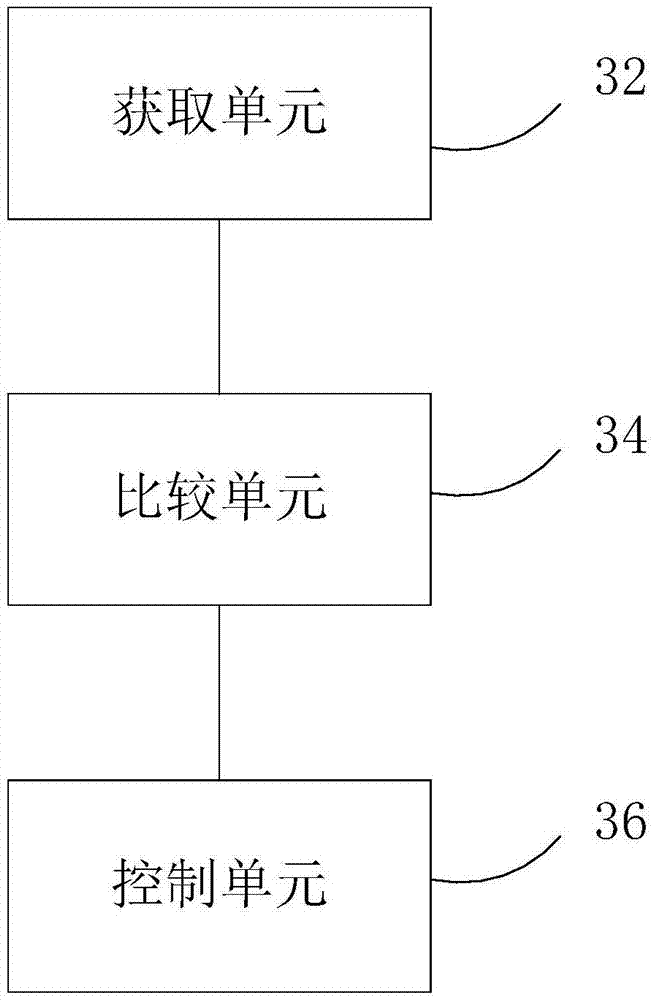

[0054] Based on the oil return control method of the frequency conversion unit provided in the above embodiment 1, the optional embodiment 3 of the present invention also provides an oil return control device for the frequency conversion unit, specifically, image 3 shows an optional structural block diagram of the device, such as image 3 As shown, the oil return control device of the frequency conversion unit includes: an acquisition unit 32 for acquiring the actual operating frequency Fs of the frequency conversion unit; a comparison unit 34 connected to the acquisition unit 32 for comparing the acquired actual operating frequency Fs with the unit preset The optimal oil return frequency Fy is compared to determine the degree of deviation between the actual operating frequency Fs and the optimal oil return frequency Fy; the control unit 36 is connected with the comparison unit 34, and is used to generate a flow for controlling the oil return solenoid valve of the frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com