Lithium battery production safety detection device

A technology of safety detection and temperature detection device, applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problems of easy explosion or fire, personal safety hazards of users, heat and heat, etc., to avoid fire or explosion. , to avoid the effect of high or low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

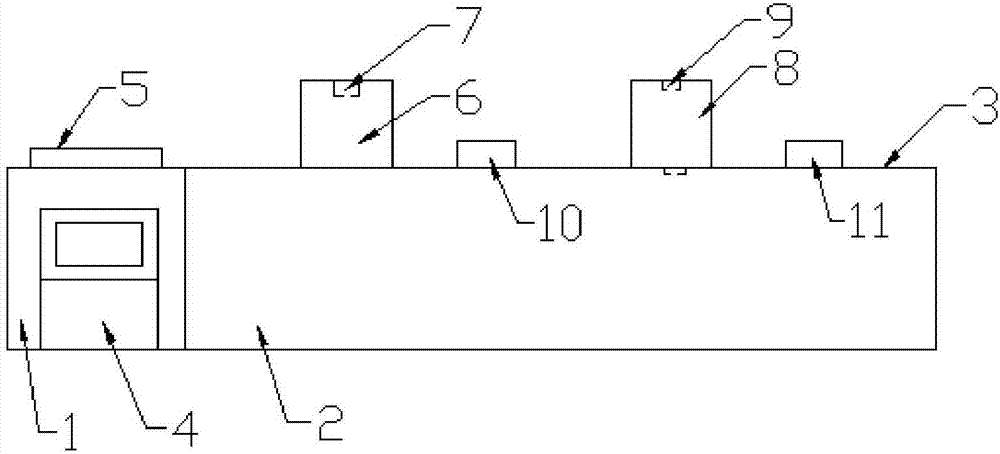

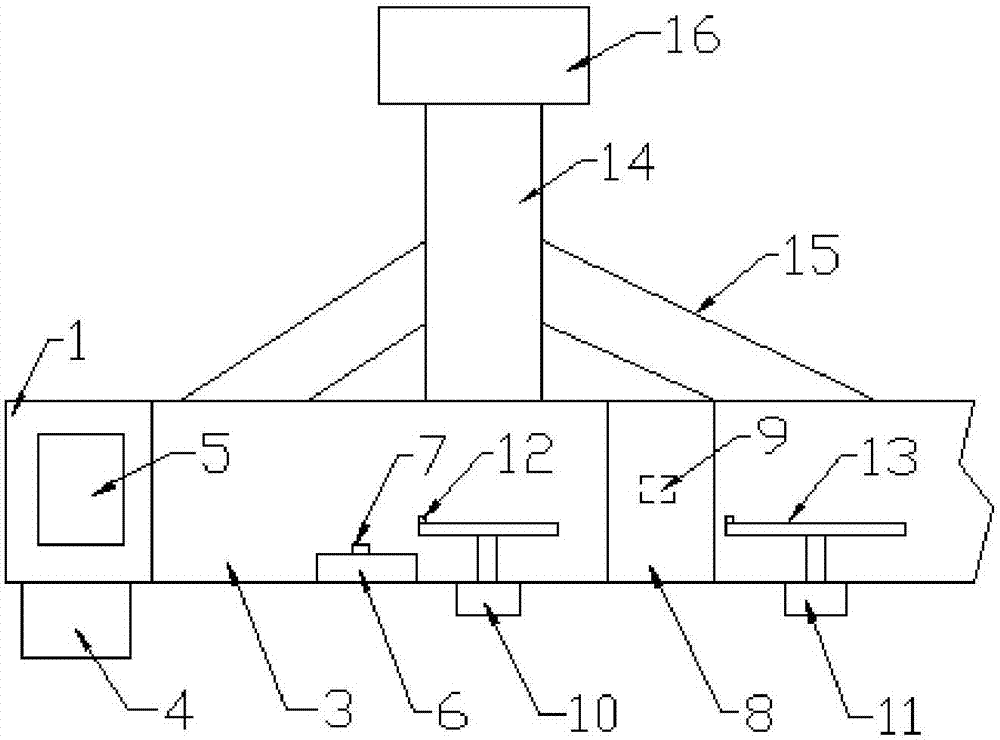

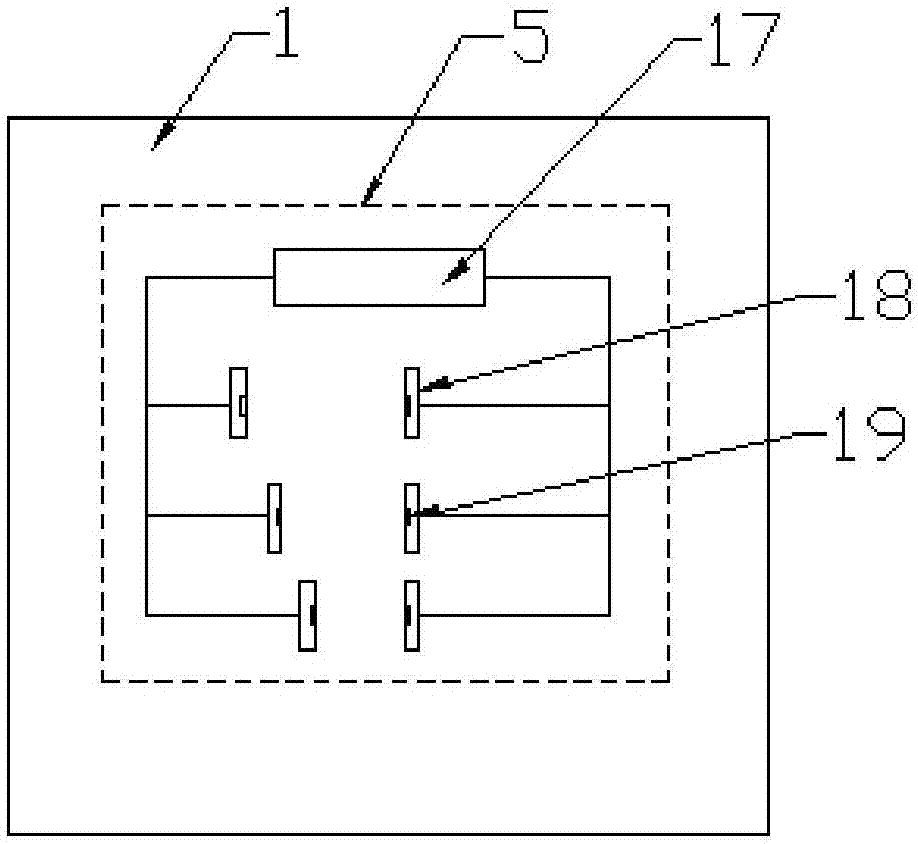

[0021] Example: such as Figure 1-5 As shown, a lithium battery production safety detection device of the present invention includes a voltage detection platform 1 and a transmission platform 2 fixed on one side of the voltage detection platform 1. The voltage detection platform 1 is provided with a voltage detection device 5, which is convenient for passing through the voltage detection device. 5 Detect whether the voltage of the lithium battery is up to the standard, if the voltage of the lithium battery is not up to the standard, then send the unqualified lithium battery into a conveyor belt 15 close to the voltage detection device 5; a No. Conveyor belt No. 3 will pass qualified lithium batteries to the next process; one end of conveyor belt 3 close to voltage detection device 5 is fixed with a temperature detection device, which is convenient for detecting whether the temperature of the lithium battery is qualified through the temperature detection device, and avoiding the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com