Ignition prevention method and ignition prevention apparatus for crusher

A pulverizer and adjustment mechanism technology, applied in the directions of combustion method, supply configuration, block/powder fuel preparation, etc., to achieve the effect of preventing fire, preventing fire and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. In addition, in the following embodiments, coal is used as a solid fuel and described, but the solid fuel is not limited thereto, and may be biomass fuel, sludge carbide, etc., and coal, biomass fuel, etc. may also be used. , Sludge carbide, etc. Two or more.

[0038] (The structure of the fire prevention device of the pulverizer)

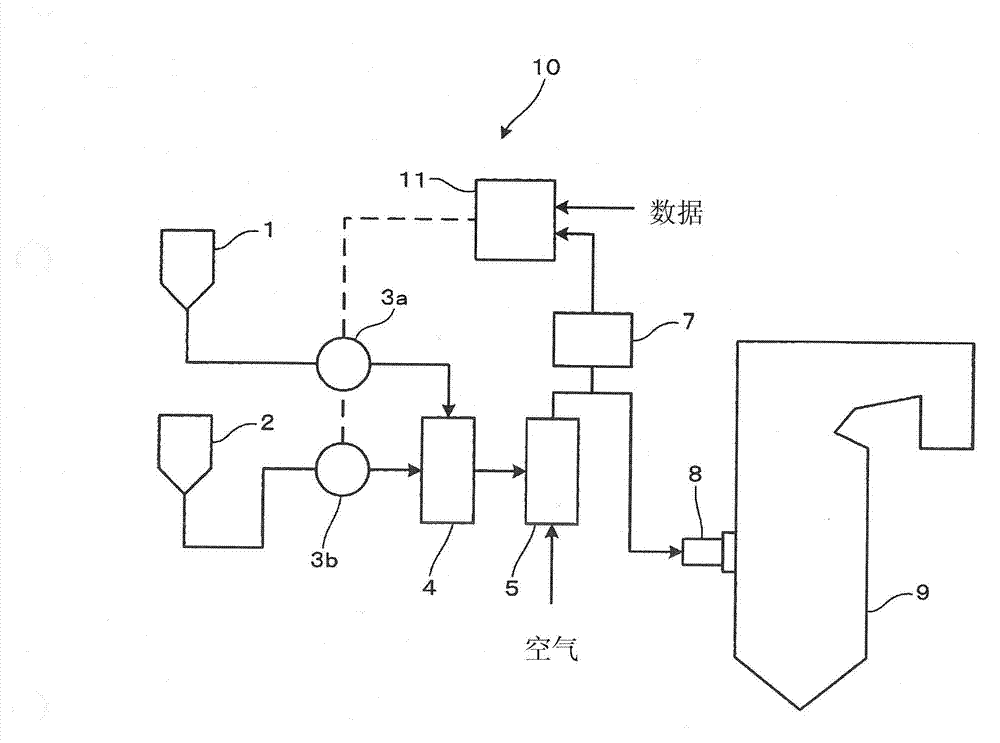

[0039] The fire prevention device 10 of the pulverizer of this embodiment, such as figure 1 As shown, it has the following: coal supply adjustment device (supply adjustment mechanism) 3a, 3b, which adjusts the supply of coal A, B supplied from coal hopper 1, 2 to mixer 4; concentration measuring device (concentration Measuring mechanism) 7, which measures the concentration of carbon monoxide in the gas at the outlet of pulverizer 5; calculator (storage mechanism, control mechanism) 11, which respectively controls the coal supply ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com