multi-piece wiper ring

A scraper ring, multi-piece technology, applied to piston rings, engine components, machines/engines, etc., can solve problems such as increased wear and damage to cylinder walls, and achieve the effect of reducing particle pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

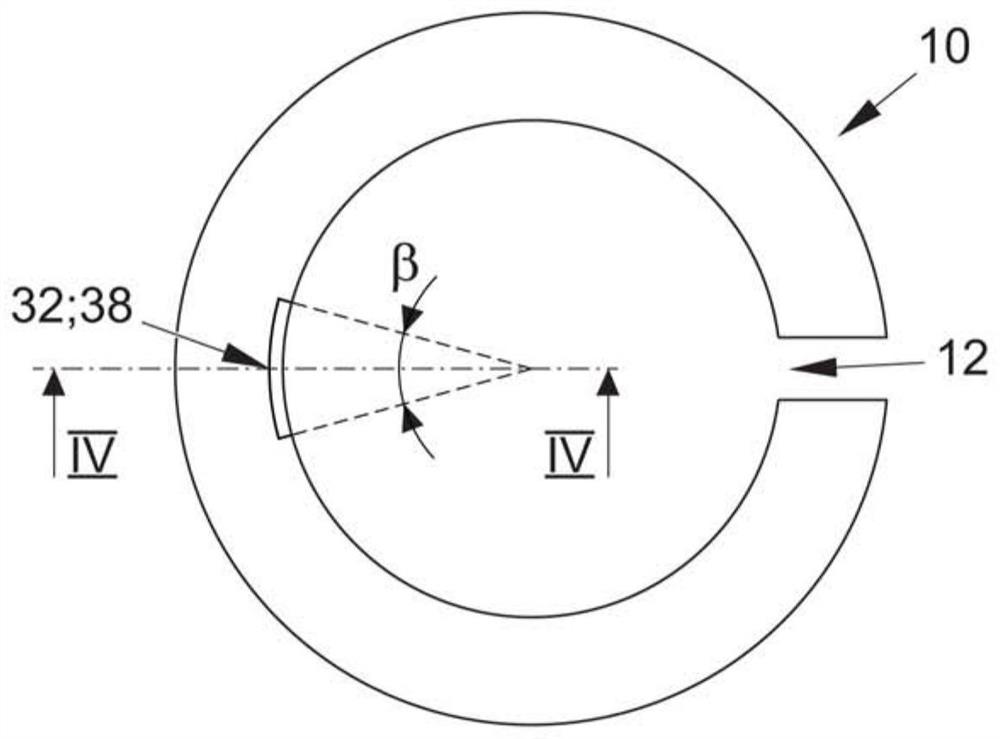

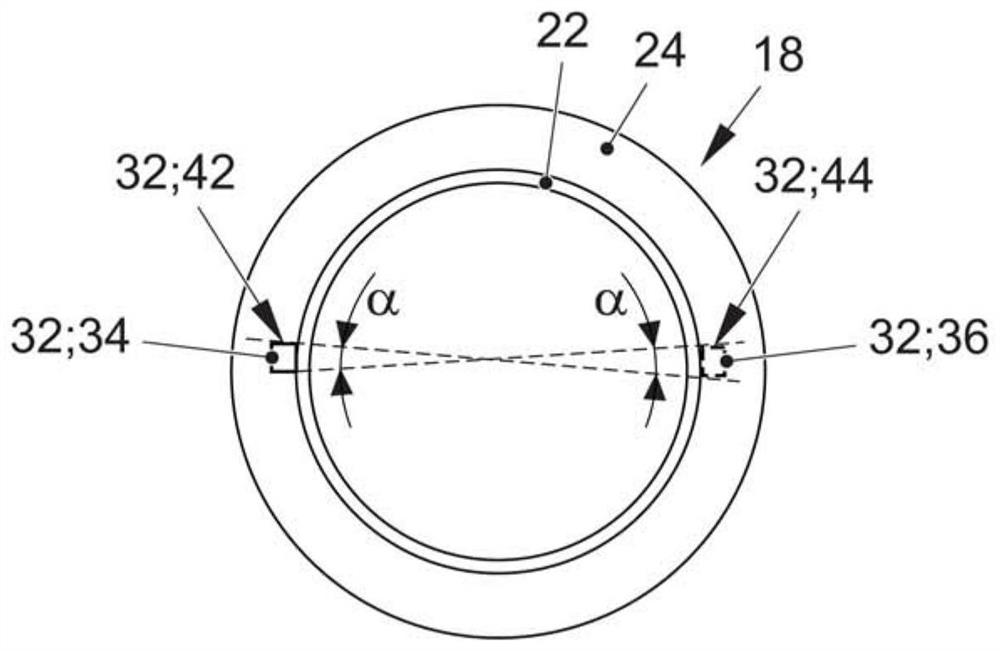

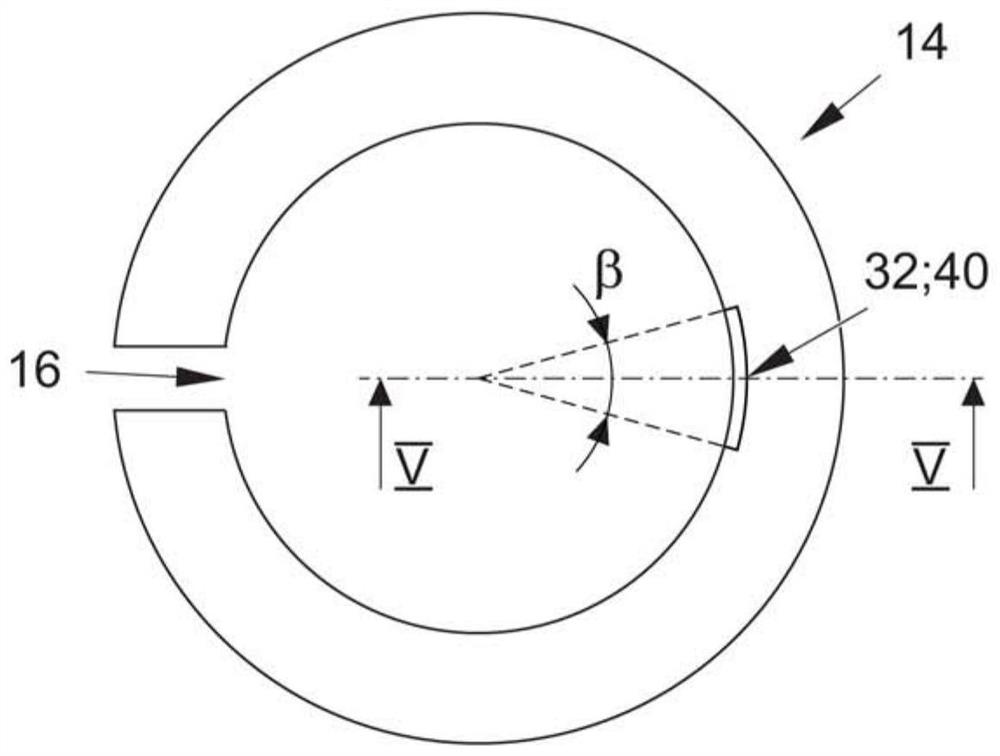

[0028] exist figure 1 shows a multi-piece wiper ring 20 according to the invention (see Figure 4 and Figure 5 ) of the first embodiment of the first ring rail 10 with the ring opening 12 . image 3 In a similar manner, a first embodiment of the second ring rail 14 with the ring opening 16 of the multi-part oil control ring 20 according to the invention is shown. figure 2 The spring 18 of the multi-part oil wiper ring 20 according to the invention according to the first embodiment is shown, together with the first torsion-limiting element 34 and the second torsion-limiting element 36 .

[0029] The first ring rail 10 , the spring 18 and the second ring rail 14 are arranged concentrically one above the other in the axial direction (ie in the direction of travel of the reciprocating piston) in the installed state of the first embodiment of the oil wiper ring 20 according to the invention. ground layout. exist Figure 4 and Figure 5 The wiper ring 20 is shown installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com