Self-inspection system based on spare part identity identifier

A self-inspection system and identification technology, applied in the field of self-inspection systems based on two-dimensional code identification ID identification, can solve problems such as waste of manpower, hidden dangers of ATM security, and awareness of self-failure maintenance personnel, so as to reduce the probability of errors, The effect of avoiding input errors and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

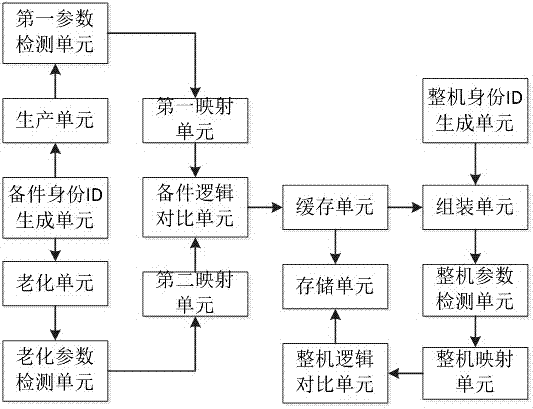

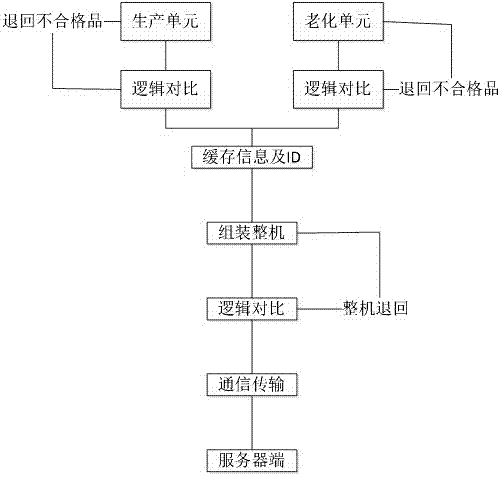

[0024] A kind of self-inspection system based on spare parts identity mark according to the present invention, its structure is as follows figure 1 shown. The system includes a spare part ID generating unit, which generates a unique ID for each spare part, and then inputs the spare part ID into an aging unit or a production unit as required. The production unit acquires the spare part ID from the spare part ID generating unit and configures it on the newly produced spare parts, and then inputs the spare part and the spare part ID into the first parameter detection unit. The first parameter detection unit detects the spare part parameters of the input spare part, and simultaneously inputs the spare part and its spare part ID and spare part parameters into the first mapping unit. The first mapping unit generates a mapping relationship between the input spare part parameters and the spare part ID, and inputs the mapped spare part, spare part ID, and spare part parameters into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com