Silage method of gramineous forage grass and medicago sativa

An alfalfa, undergraduate technology, applied in the field of grass grass and alfalfa silage, can solve the problems of increasing the number of lactic acid bacteria, poor fermentation, etc., and achieve the effect of increasing the number of lactic acid bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

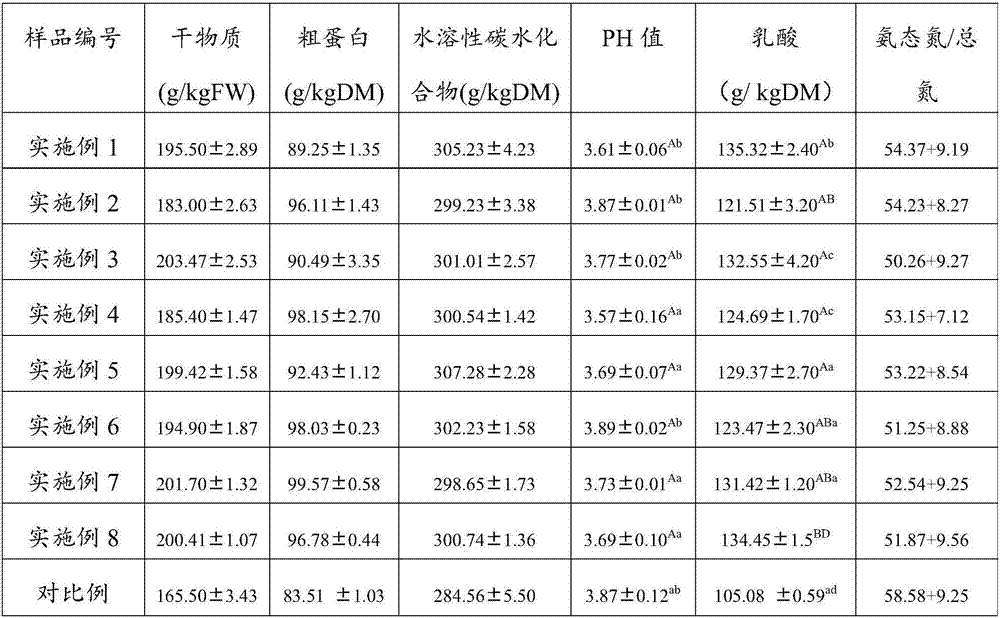

Examples

Embodiment 1

[0030] A kind of silage method of gramineous grass and alfalfa, comprising the following steps:

[0031] A, harvesting: the alfalfa at the early flowering stage and the sorrel at the heading stage are harvested for subsequent use;

[0032] B, drying: the harvested alfalfa and sago dan grass are dried, the temperature of the drying process is 80 ℃, and the time is 3 hours, and the water content of the dried alfalfa and sago dan grass is 65%;

[0033] C, chopped: the dried alfalfa, sago dan grass and corn stalks were chopped respectively to obtain the alfalfa primary material, sago dan grass primary material and stalk primary material with a length of 4 cm;

[0034] D, mixed fermentation: the first material of alfalfa, the first material of Sorbus alfalfa and the first material of straw are mixed uniformly, and the weight ratio of the first material of alfalfa, the first material of Sorbus and the first material of straw is 40:45:15, and the obtained Mixed material, the mixed m...

Embodiment 2

[0036] A kind of silage method of gramineous grass and alfalfa, comprising the following steps:

[0037] A, harvesting: the alfalfa at the early flowering stage and the sudan grass at the booting stage are harvested for subsequent use;

[0038] B, drying: the alfalfa and sudan grass after harvesting are dried, the temperature of drying treatment is 110 ℃, the time is 1 hour, the water content of alfalfa and sudan grass after drying is 75%;

[0039] C, chopped: the dried alfalfa, sudangrass and wheat straw were chopped respectively to obtain the alfalfa primary material, sudan grass primary material and straw primary material with a length of 2 cm;

[0040] D, mixed fermentation: the alfalfa primary material, sudan grass primary material and straw primary material are mixed evenly, and the weight ratio of the alfalfa primary material, sudan grass primary material and straw primary material is 50:35:25 to obtain a mixture , bundle the mixture into cylinders with a packing densi...

Embodiment 3

[0042]A kind of silage method of gramineous grass and alfalfa, comprising the following steps:

[0043] A, harvesting: harvesting the alfalfa at the early flowering stage and the forage sweet sorghum at the heading stage for subsequent use;

[0044] B. Drying: drying the harvested alfalfa and forage sweet sorghum, the temperature of the drying treatment is 95° C., and the time is 2 hours, and the moisture content of the dried alfalfa and forage sweet sorghum is 70%;

[0045] C, chopping: the dried alfalfa, forage sweet sorghum and millet stalks are chopped respectively to obtain the alfalfa primary material, forage sweet sorghum primary material and straw primary material with a length of 3 cm;

[0046] D, mixed fermentation: the alfalfa initial material, forage sweet sorghum initial material and straw initial material are mixed evenly, and the weight ratio of the alfalfa initial material, forage sweet sorghum initial material and straw initial material is 45:40:20 , get the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com