Combined type scraper filtering device for alkyd resin and control method thereof

A technology of alkyd resin and scraper filtration, which is applied in the direction of filtration separation, filtration circuit, separation method, etc. It can solve the problems of large economic loss, high cost of delivery and processing, etc., and achieve improved resin yield, convenient disassembly and maintenance, and effective treatment good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

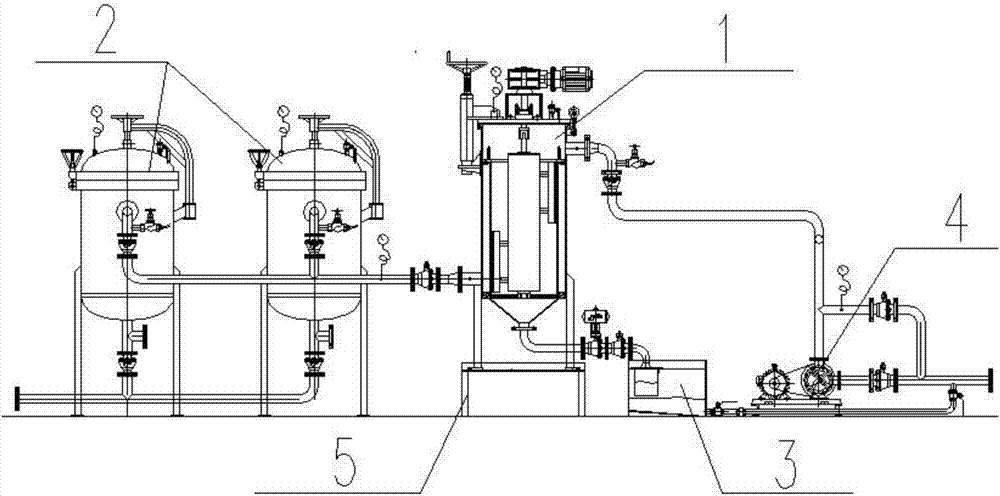

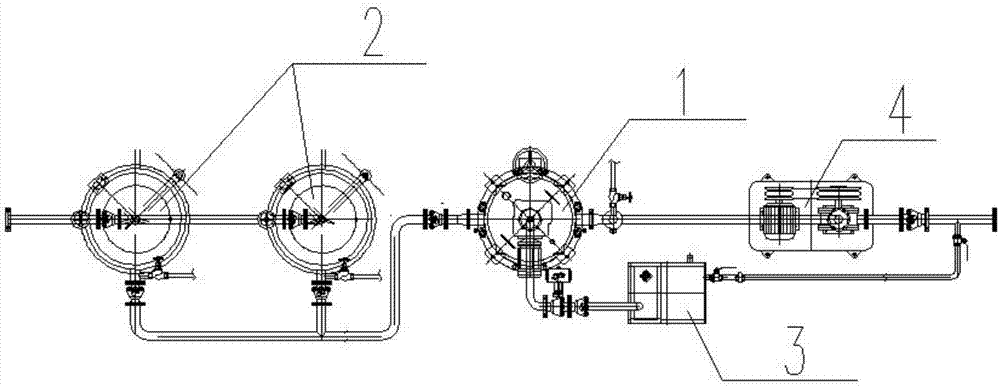

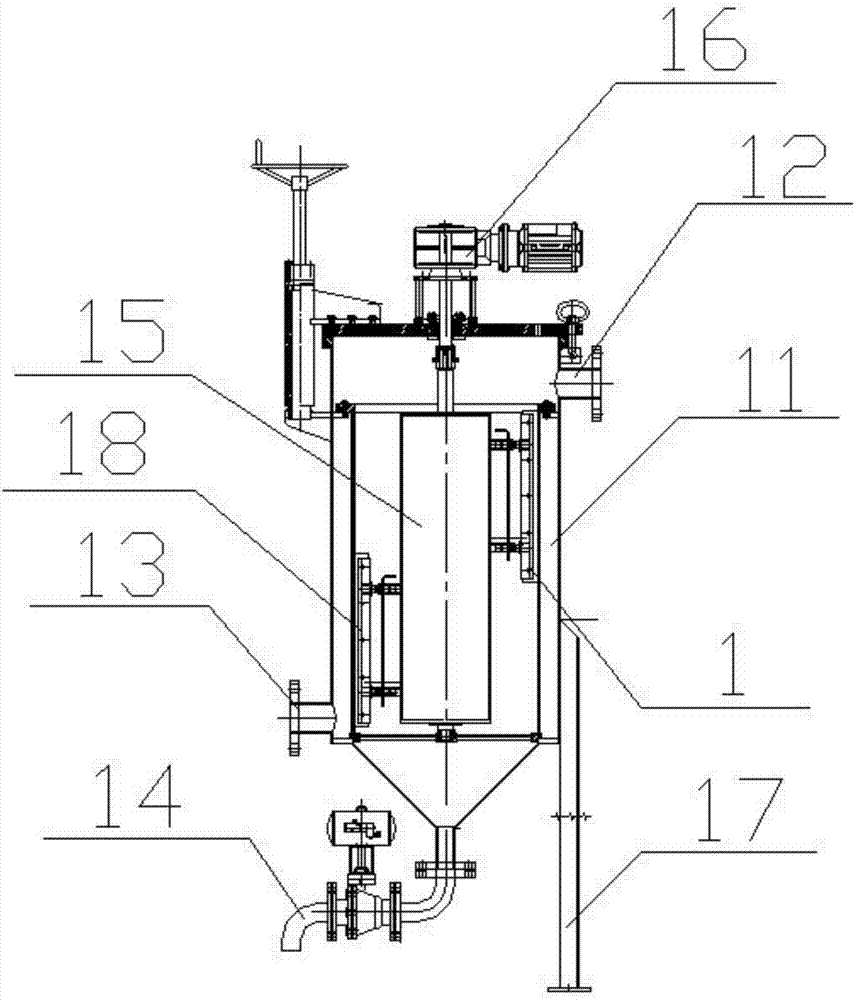

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a composite scraper filter device for alkyd resin filtration of the present invention, comprising a knife filter 1, a bag filter 2, a mud and slag emerald extraction device 3, a feeding device 4, and the knife filter 1 is composed of The tank body 11, the rotating shaft 15, the driving device 16, the fixed frame 17, several scraper assemblies 18 and fasteners are installed and connected to each other, and the left lower end of the knife filter 1 is connected with several bag filters 2. The bottom of the knife filter 2 is connected with the sludge removal device 3 with a slag discharge pipe 14, and the upper right side of the knife filter 1 is connected with the feeding device 4 with an input pipe. The fixed frame 17 Fixed on the cement platform 5, the bag filter 2 is composed of a body 21, a bracket 22, a filter bag 24, a sealing head 26 and a number of connectors connected to each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com