Welding fixture with marking function

A technology of welding tooling and marking function, which is applied in the field of welding tooling with marking function, to achieve the effects of easy identification, difficult removal of marks, and avoiding the disappearance of marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

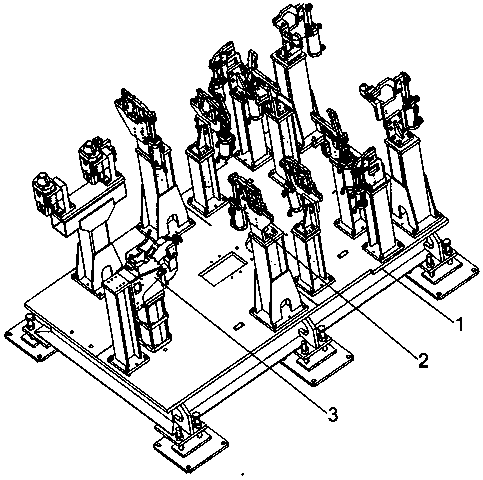

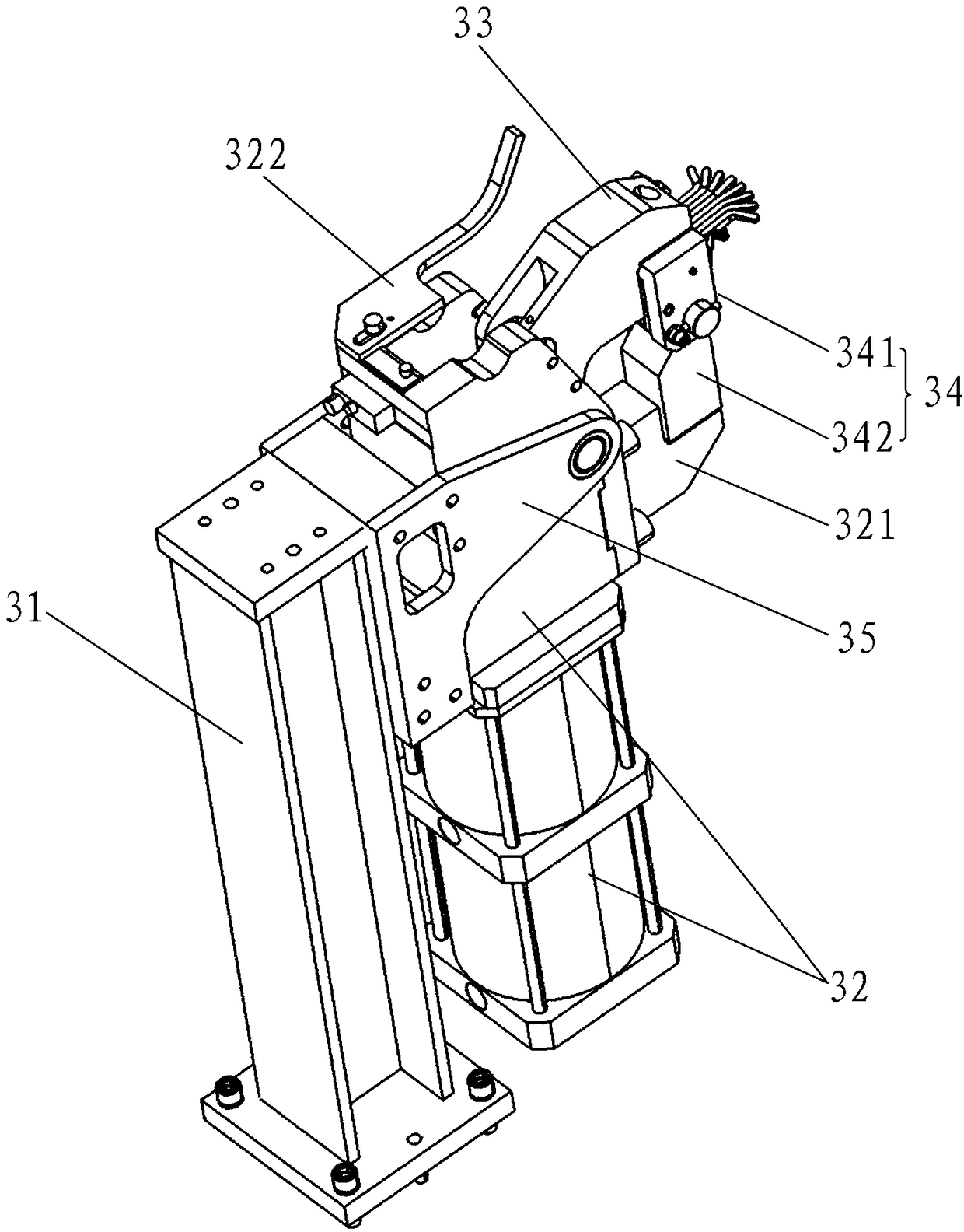

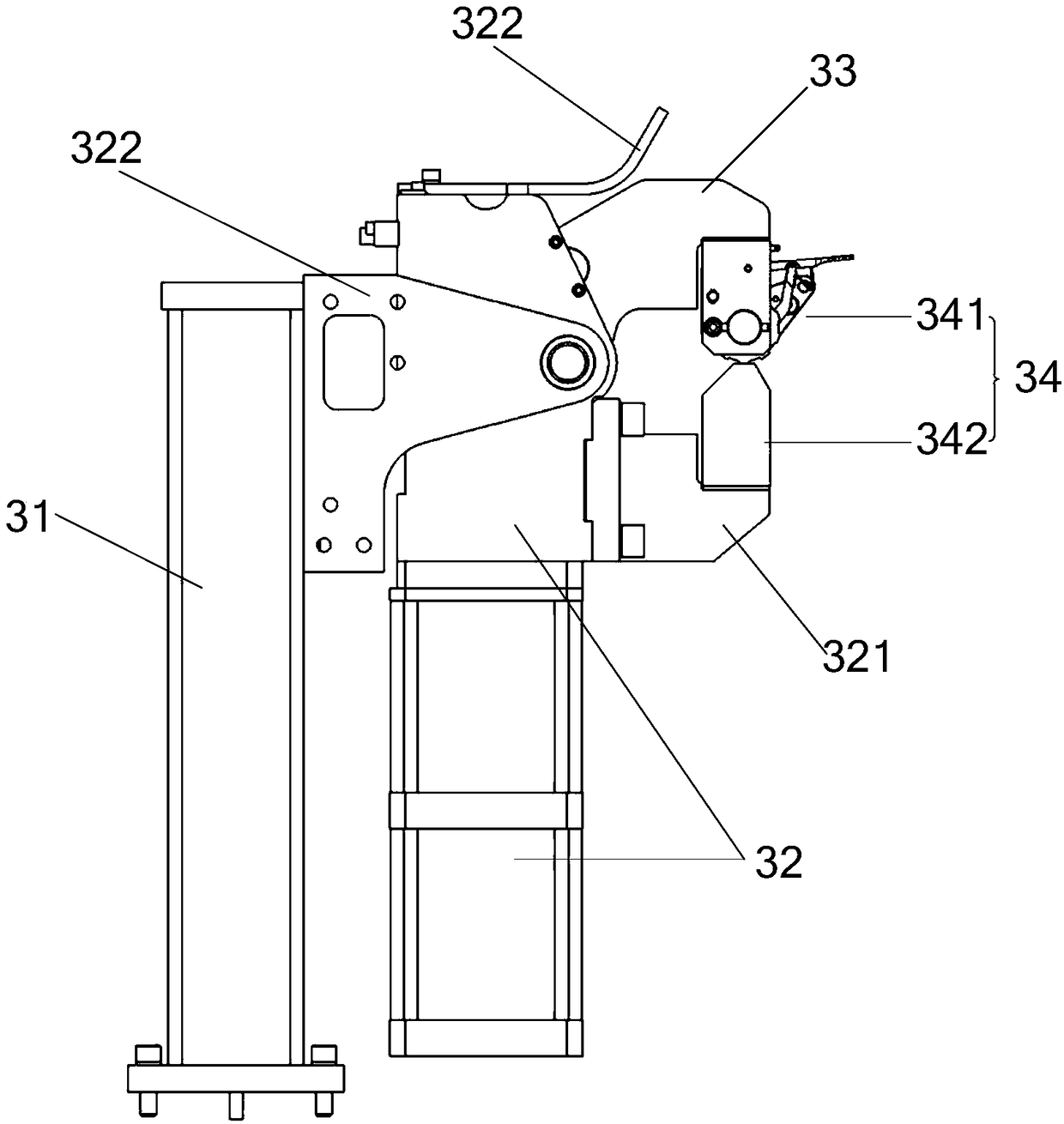

[0035] Embodiments of the present invention: as Figure 1-3 As shown, a welding tool with a marking function includes a base 1 and a welding jig 2 and a marking jig 3 fixed on the base 1 . The marking fixture 3 includes a fixing base 31, a driving device 32, a pressing arm 33 and a marking device 34, the fixing base 31 is fixed on the base 1, the driving device 32 is fixed on the fixing base 31, and Drive the pressing arm 33 to compress or open; the marking device 34 is fixed on the pressing arm 33, and has a marking protrusion on the surface close to the workpiece to be welded. Driven by the pressing arm 33, the workpiece Compression is carried out to realize the marking of the workpiece. Specifically, the driving device 32 is fixed on the fixing seat 31 through a driving mounting plate 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com