Radial plug-in type internal spline broaching clamp

A plug-in, internal spline technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of reducing workpiece positioning accuracy, waste of resources, and workpiece position error, and achieve improved positioning accuracy and processing accuracy, convenient installation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

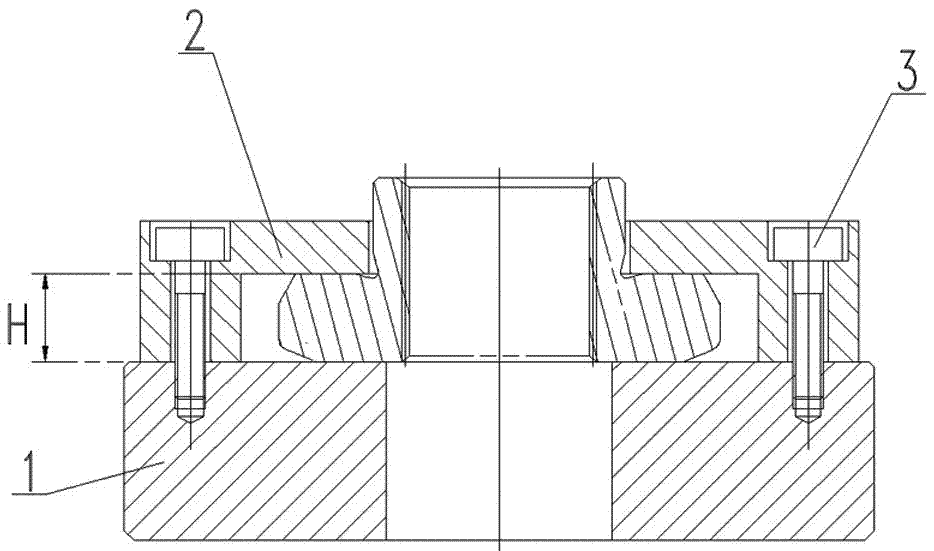

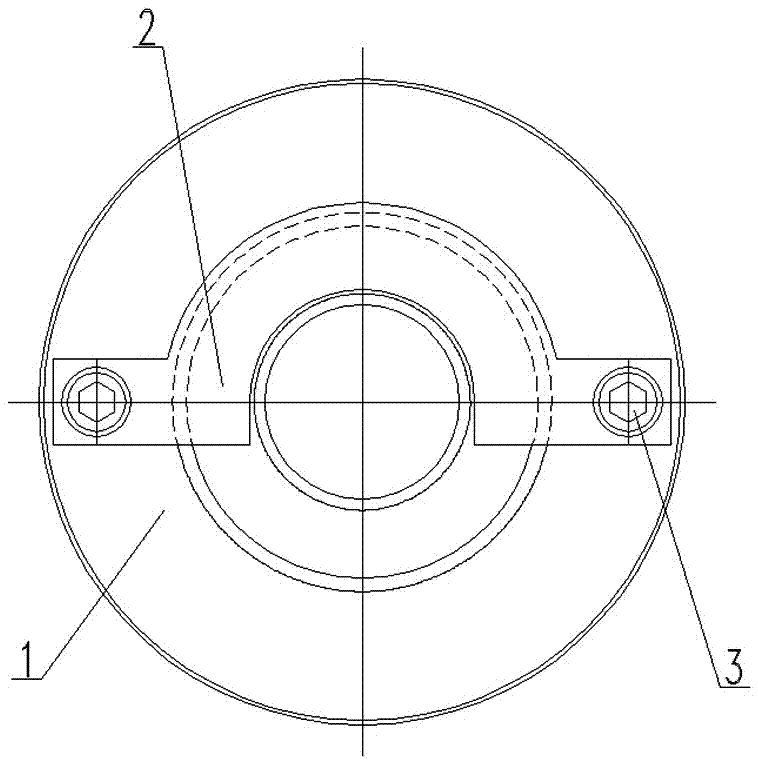

[0015] figure 1 The shown radial insertion type internal spline broaching fixture is a schematic diagram of an embodiment of the internal spline broaching fixture for a shift gear of a car transmission. The base 1 is a basic component, which is a circular flange with an axial process hole reserved in the middle for the broach to pass through. The limit block 2 is a special-shaped member placed on one end surface of the seat body 1. The two sides of the opening end of the semicircular ring are respectively provided with legs protruding radially outward, which are used to pass through the legs of the bolt 3 toward the One side of the seat body 1 is a shoulder structure, and the reserved height H of the shoulder is equal to the nominal thickness of the workpiece tooth, and only a deviation of 0.05-0.15 mm is allowed. In this embodiment, d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap