Tubular product hole forming fixing clamp

A technology for fixing fixtures and pipes, applied in the direction of clamping, positioning devices, manufacturing tools, etc., can solve the problems of deviation in the direction and angle of the opening, difficulty in fixing, and affecting the assembly of pipes, etc., to achieve improved accuracy and simple structure , Easy to install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0015] The pipe opening fixing fixture of the present invention is mainly suitable for fixing cylindrical pipes to achieve the purpose of opening holes on the cylindrical pipes.

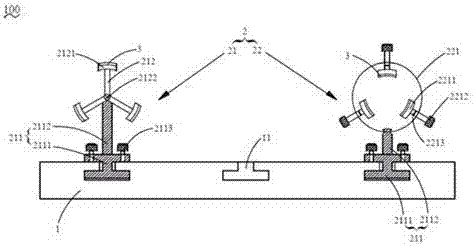

[0016] See figure 1 As shown, the present invention discloses a pipe hole fixing fixture 100, which comprises a base plate 1 and a plurality of pipe fixing frames 2 arranged on the base plate 1.

[0017] The base plate 1 is arranged in a plate shape as a whole, and the base plate 1 is provided with sliding grooves 11 staggered horizontally and vertically, and the sliding grooves 11 are arranged in a "T" shape. Specifically, there are multiple chutes 11 in parallel in the same direction, and the transverse and longitudinal chutes 11 are arranged perpendicular to each other a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com