Method and device for supplying rubber raw material to injection machine

A technology of rubber raw materials and injection machines, which is applied in the field of polymer processing, and can solve problems such as shortage, reciprocal movement of injection machines, and affecting the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

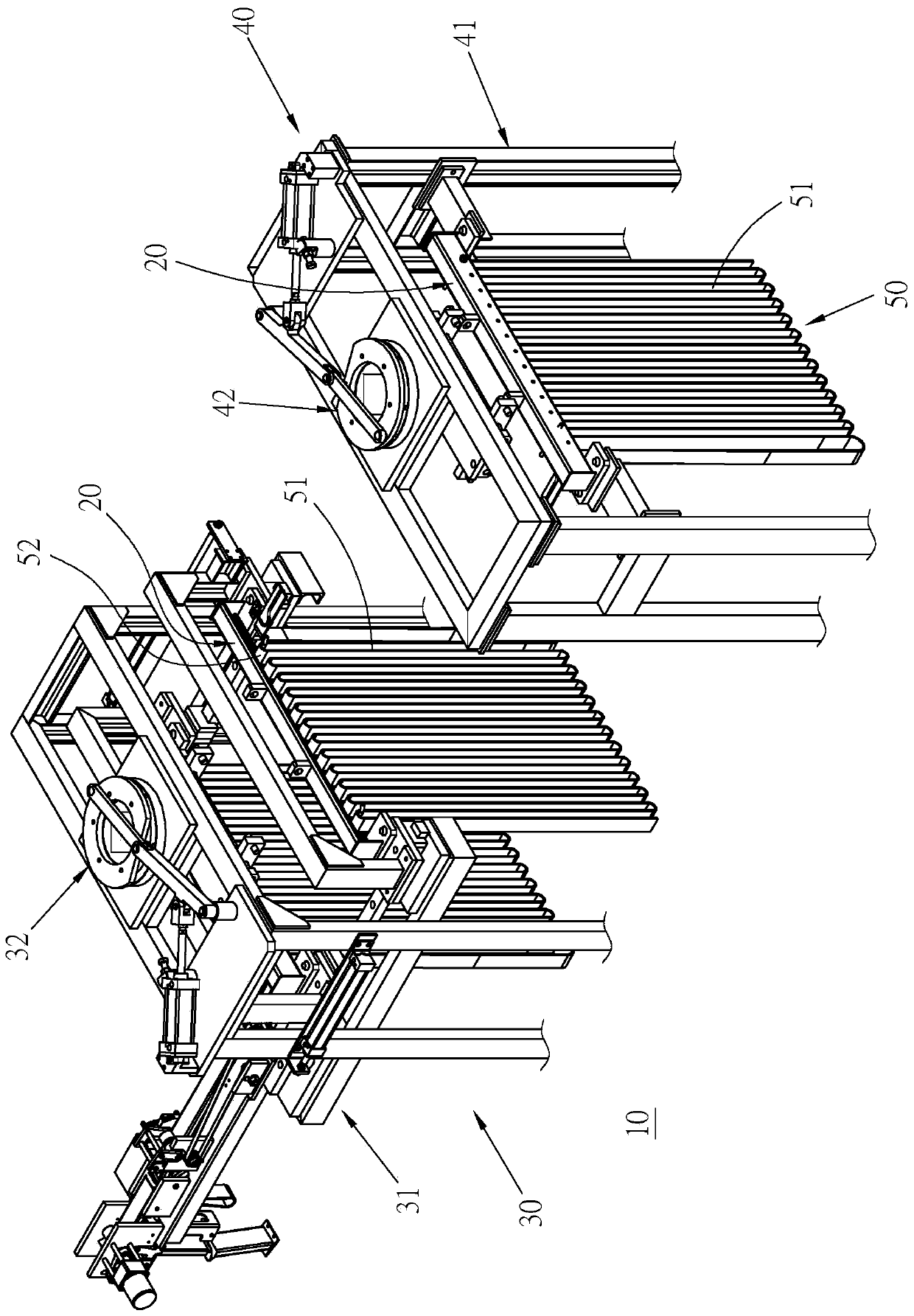

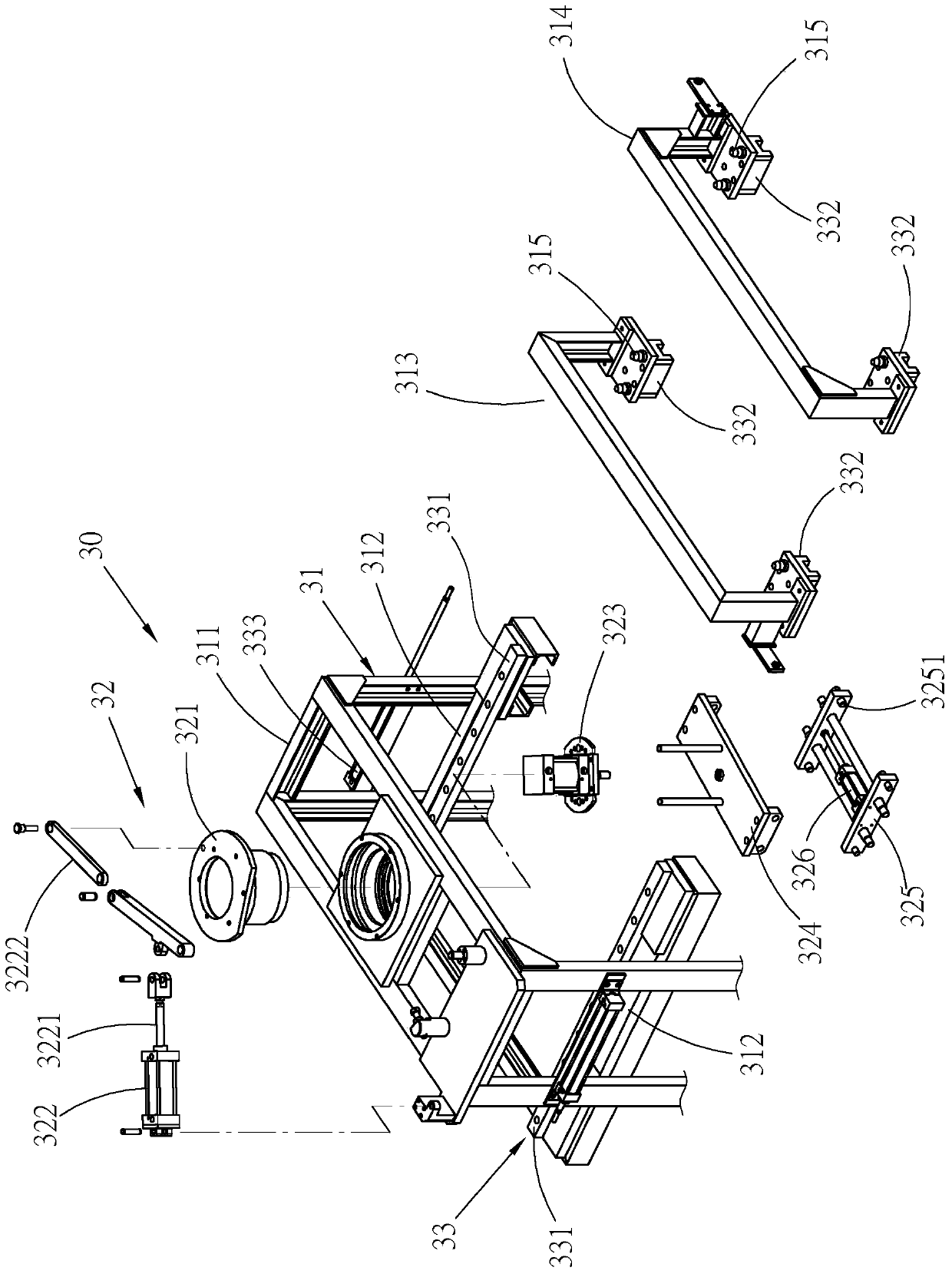

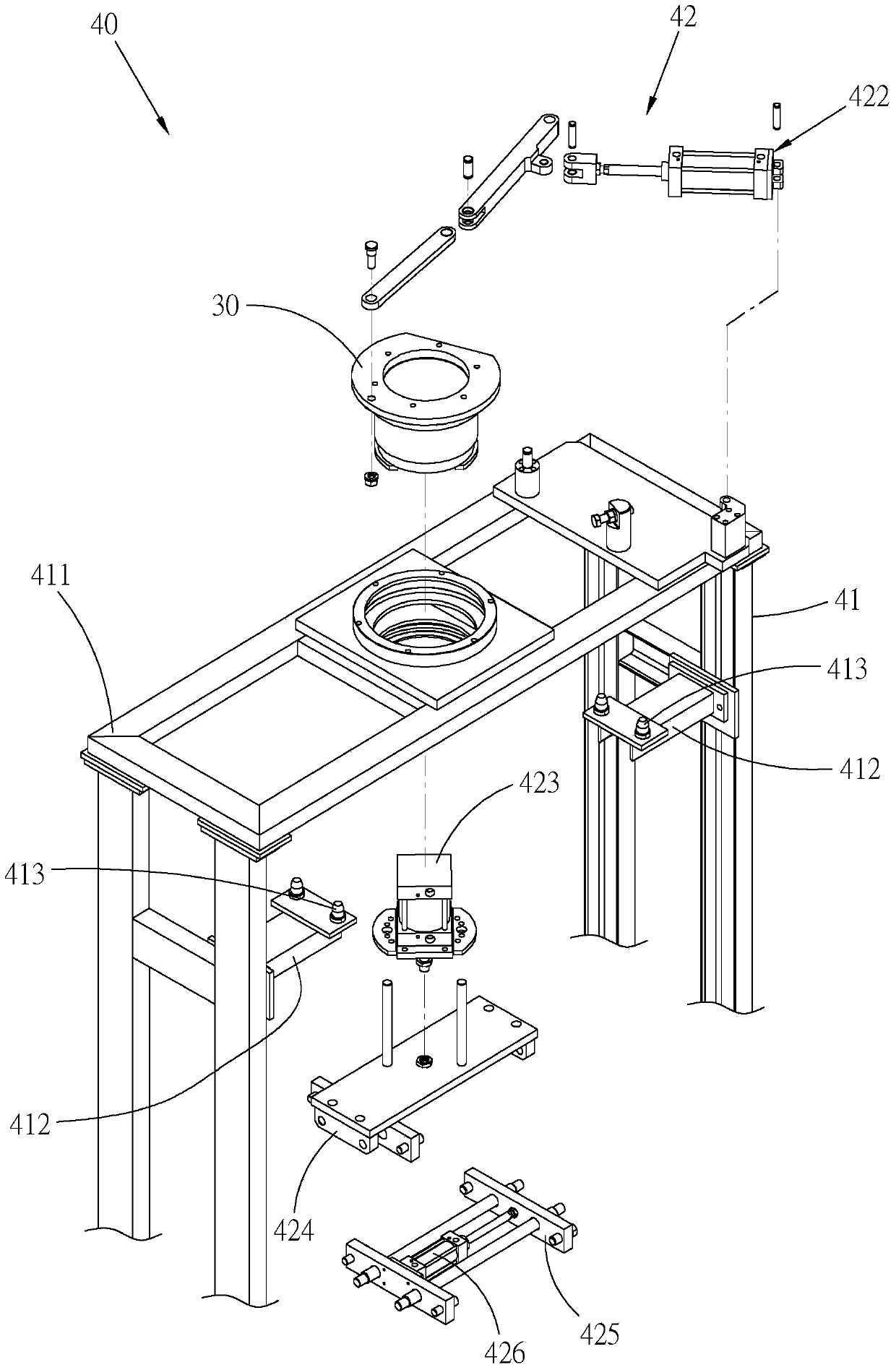

[0030] First, see Figure 1 to Figure 4 As shown, the device and method 10 for supplying rubber raw materials to the injection machine provided in a preferred embodiment of the present invention mainly include a plurality of pendants 20, a first carrying mechanism 30 and a second Carrying mechanism 40 .

[0031] Each of the pendants 20 has a square rod-shaped main body 21 of an appropriate length, and a plurality of rod-shaped hanging bodies 22 are spaced apart in sequence along the long axis of the main body 21 and extend outward from one side of the main body 21 respectively. length, and parallel to each other, the plurality of accommodation spaces not shown in the figure are respectively between the adjacent hanging bodies 22, and the two piers 23 are respectively protruded below the two ends of the long axis of the body 21, and the plurality of Positioning holes 24 are respectively provided on the piers 23 , two hanging ears 25 protrude above the middle part of the body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com