Prilling tower stiff beam hoisting device and method

A hoisting device, stiff beam technology, applied in transportation and packaging, load hoisting components, trolley cranes, etc., can solve problems such as large construction difficulties and safety hazards, and achieve low hoisting difficulty, strong bearing capacity, and safety. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

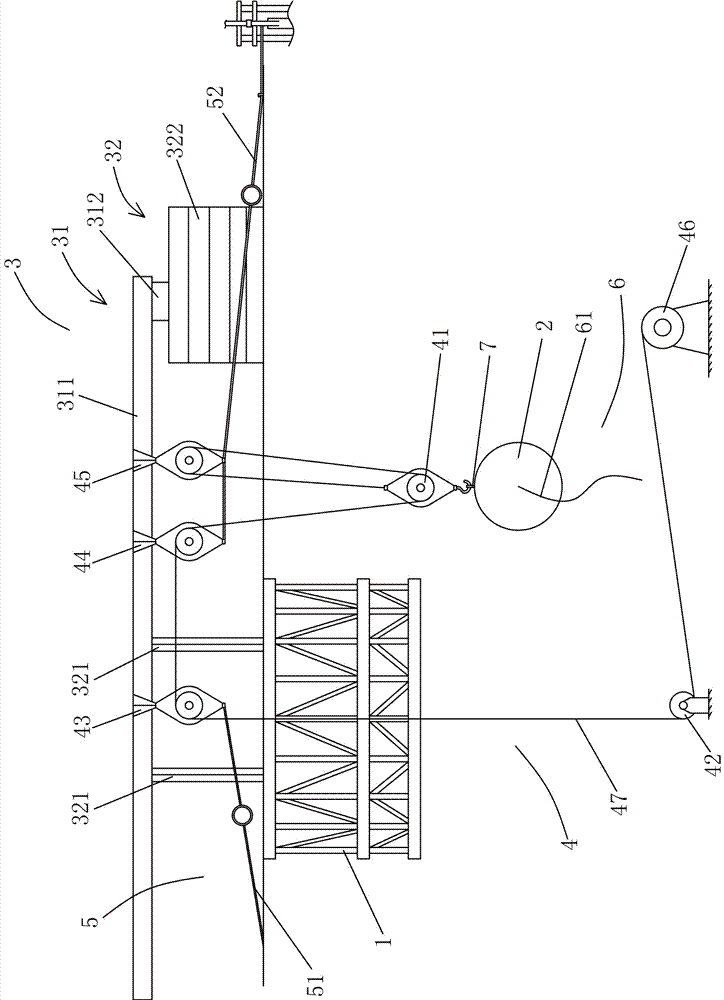

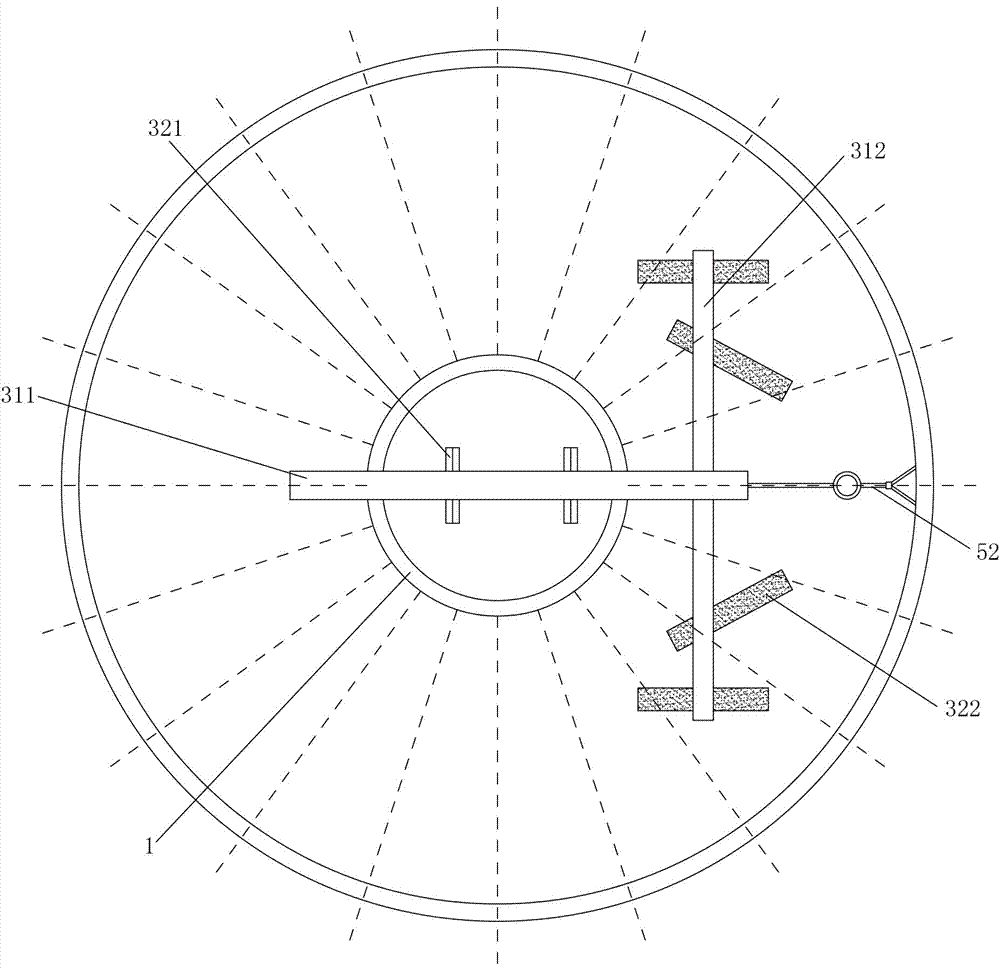

[0040] Further, see figure 1 , as a specific embodiment of the granulation tower rigid beam hoisting device provided by the present invention, the pulley hoisting mechanism 4 includes a movable pulley 41, a first fixed pulley 42, a second fixed pulley 43, a third fixed pulley 44, a fourth fixed pulley Pulley 45, winch 46 and suspension wire 47, the first fixed pulley 42 is fixedly connected with the bottom of the silo main body 1, the second fixed pulley 43, the third fixed pulley 44 and the fourth fixed pulley 45 are along the long axis of the first support beam 311 The direction is set in the lower part of the first support beam 311 in turn, the distance from the second fixed pulley 43 to the second support beam 312 is greater than the distance from the fourth fixed pulley 45 to the second support beam 312, and the winch 46 is located at the bottom of the silo main body 1 One end of the suspension wire 47 goes around the first fixed pulley 42, the second fixed pulley 43, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com