Vertical downlead grounding device for transformer substation

A technology of grounding device and down conductor, which is applied in substation grounding layout, conductive connection, electrical component connection, etc., can solve problems such as low construction efficiency, insufficient clamping force, and potential safety hazards, and reduce high falls and electric shocks Risk, good fluidity, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

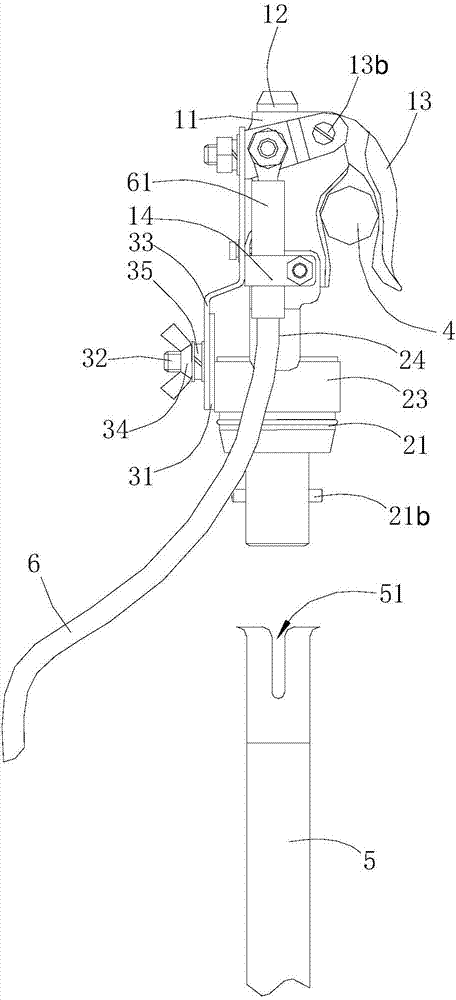

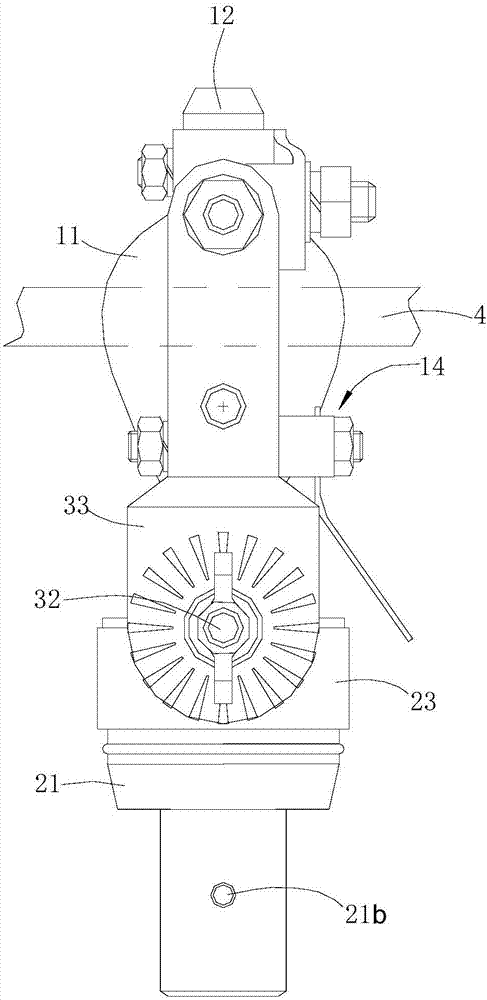

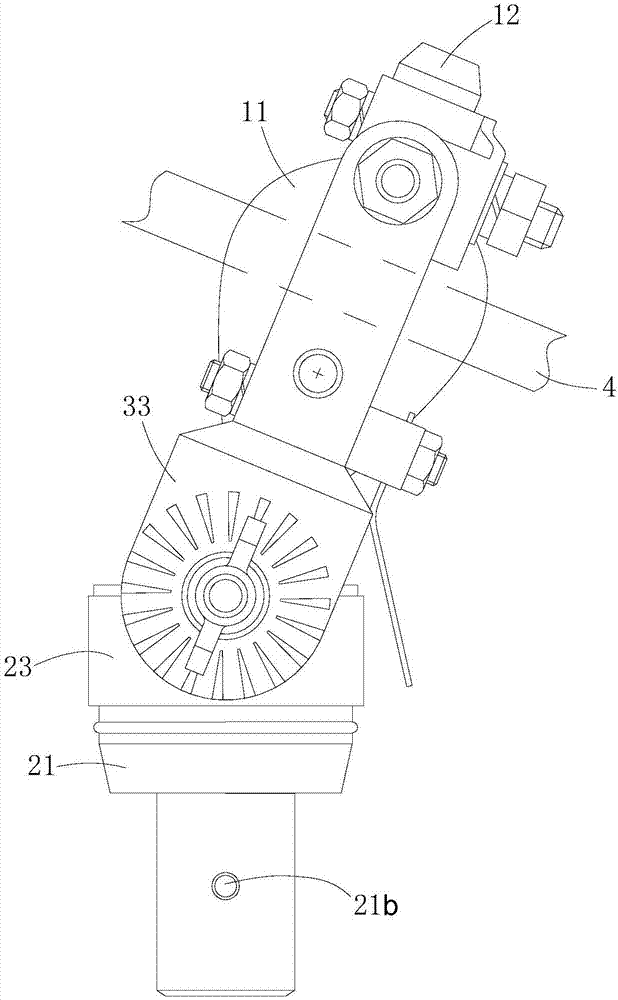

[0028] Such as Figure 1 to 6 Shown ( Figure 2 to 4 The ground connection wire 6 and the mounting rod 5 are omitted)

[0029] The grounding device includes a grounding clamp, a grounding connection wire 6 and a mounting rod 5.

[0030] The grounding clamp includes a clamping assembly, a screwing assembly and a damping steering assembly.

[0031] The wire clamping assembly is at the upper position of the grounding wire clamp. The wire clamping assembly includes a wire clamping shell 11, an arc-shaped clamping plate 13 and a rotating rod 12. The wire clamping shell 11 is provided with a cavity 11a. The cavity 11a has upper, lower, and right openings. The cross-sectional shape of the wire clamping housing 11 is generally a "凵" shape. The side wall of the right opening of the wire clamping housing 11 is provided with an arc-shaped first clamping notch. 11b, the first clamping notch 11b fits the outer contour of the wire 4, the rotating rod 12 is placed in the cavity 11a of the wire cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com