Pickling equipment for bamboo shoots

An equipment and technology for bamboo shoots, applied in the field of processing equipment, can solve the problems of uneven distribution of salt, affecting the flavor of bamboo shoots, and difficulty in contacting bamboo shoots with salt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

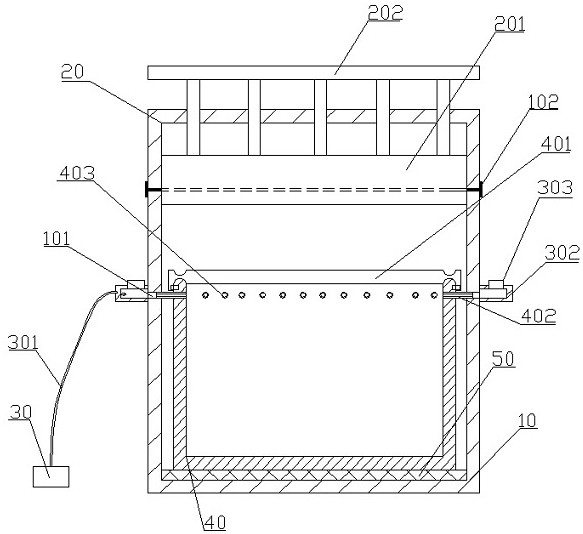

[0015] The reference signs in the drawings of the description include: pickling box 10, second inlet hole 101, sealing strip 102, shell cover 20, piston 201, exhaust rod 202, blower 30, ventilation pipe 301, placement box 302, plugging Block 303 , inner cylinder 40 , handle 401 , connecting pipe 402 , third inlet hole 403 , gravity sensor 50 .

[0016] The embodiment is basically as attached figure 1 Shown: pickling equipment for bamboo shoots, including a pickling box 10, an induction mechanism, a holding mechanism, a spraying mechanism and an exhaust mechanism. The upper end of the pickling box 10 is open, and the opening is fixedly bonded with a seal Article 102.

[0017] The exhaust mechanism includes a case cover 20, a piston 201 and a vertically arranged exhaust rod 202. The lower end of the case cover 20 can be in close contact with the upper surface of the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com