Sheep hoof trimming integrated machine

An all-in-one machine and sheep's hoof technology, applied in medical science, veterinary instruments, veterinary surgery, etc., can solve the problems of affecting growth, kicking, laborious and time-consuming, etc., and achieve the effect of convenient movement and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

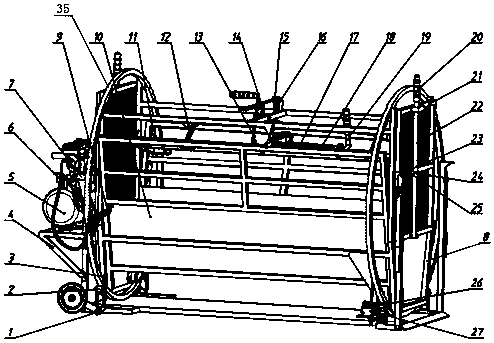

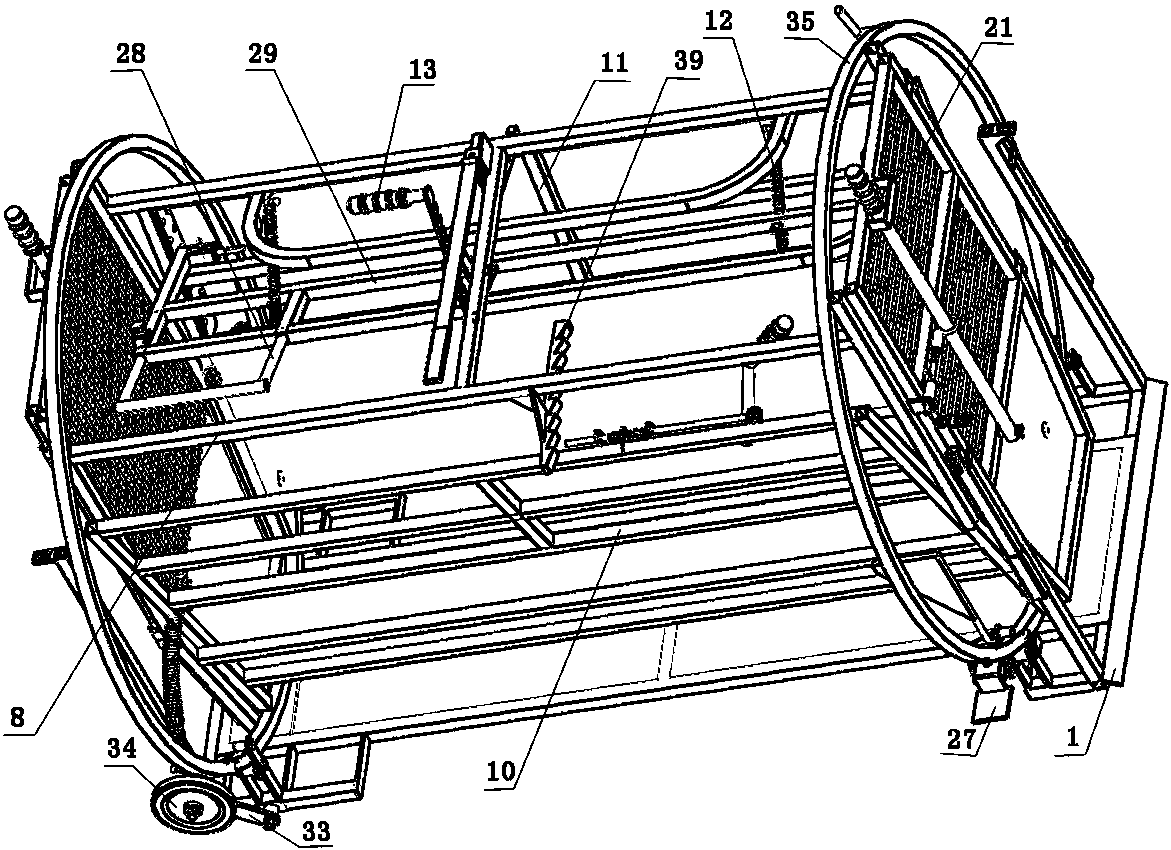

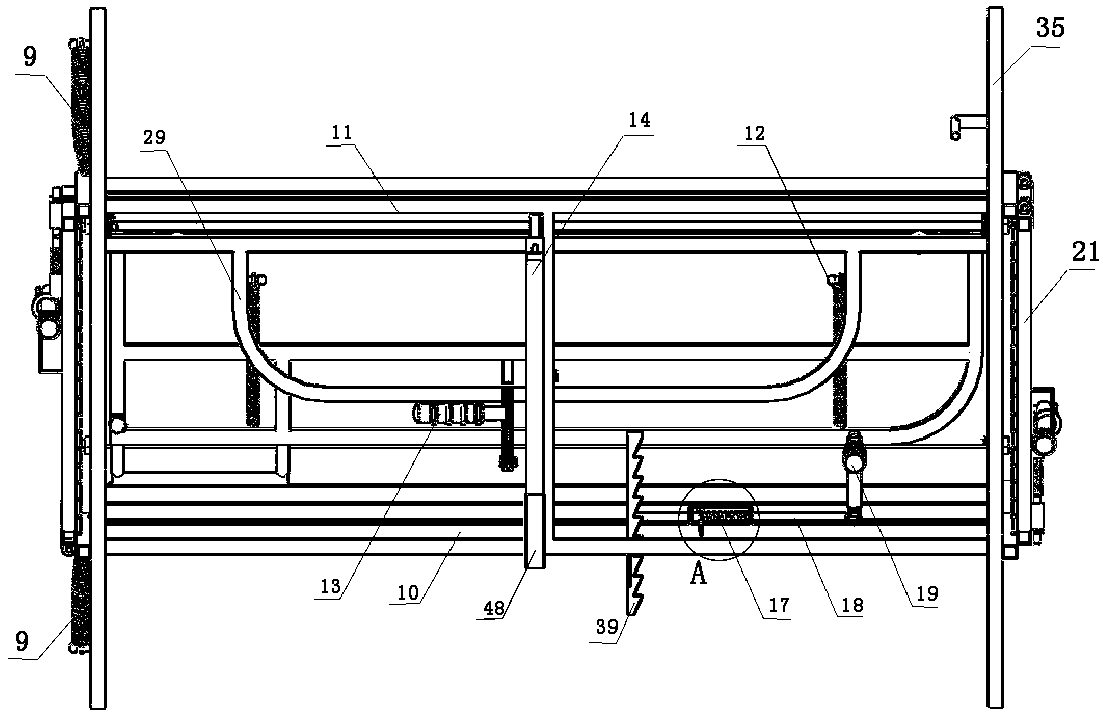

[0041] as attached Figure 1-17As shown, the all-in-one machine for trimming sheep's hooves includes a rotating frame, a clamping part and a back positioning mechanism installed on the base 1, one end of the base 1 is provided with a flip positioning mechanism, and the clamping part includes a front clamping frame 10 hinged with the rotating frame. And the rear clamping frame 11, the front clamping frame 10 and the rear clamping frame 11 are welded by galvanized square tube and galvanized sheet, and are connected with the main frame 8 by bolts and their own shafts, which can be opposite to the main frame 8. Rotate around the axis to realize the clamping function; the front clamping frame 10 is fixed with a first bracket 47, the first bracket 47 is mainly composed of two supports 40, and the support 40 is provided with a pin hole for installing the front release pin 18 , the front release pin 18 is sleeved with a spring II17, the spring II17 is located between the two supports ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com