Alum feeding device for wastewater treatment

A sewage treatment and feeding device technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of waste and inability to effectively control the dosage, and achieve improvement Work efficiency, reduce staff workload, good growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

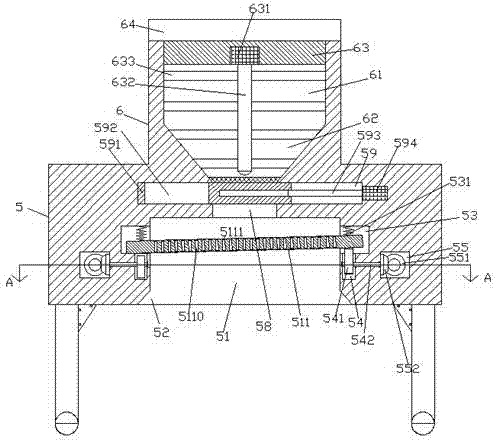

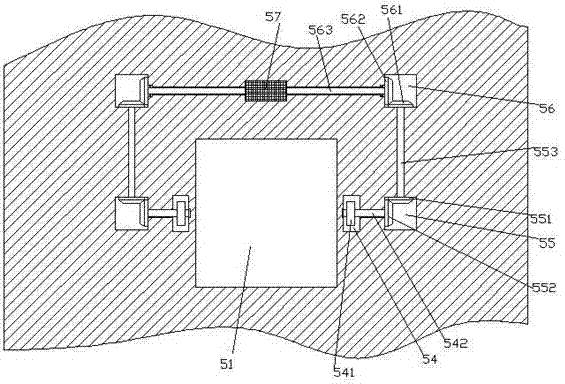

[0019] Such as Figure 1-Figure 4 As shown, an alum dosing device for sewage treatment of the present invention includes a dosing machine 5 and a storage box 6 installed on the top of the dosing machine 5, the storage box 6 is provided with a storage cavity 61, and the storage cavity 61 The bottom of the cone-shaped cavity 62 is communicated with a downwardly extending cone-shaped cavity 62, the bottom of the cone-shaped cavity 62 extends into the dispenser 5, and the bottom of the cone-shaped cavity 62 is provided with the dispenser 5 A connecting hole 58 extending downward, the bottom of the connecting hole 58 is elongated and the tail is connected with an injection slot 51, and the bottom of the injection slot 51 is connected with an injection port 52 that penetrates the bottom surface of the injection machine 5. The side of the connecting hole 58 adjacent to the cone-shaped cavity 62 is provided with a sliding cavity 59 extending left and right. The sliding cavity 59 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com