A dense sub -micron crystal β ″al 2 o 3 Products, preparation methods and applications

A dense submicron and submicron technology, which is applied in the field of its preparation and dense submicron β"-Al2O3 products, can solve problems such as residues, achieve the effects of inhibiting diffusion, reducing costs, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

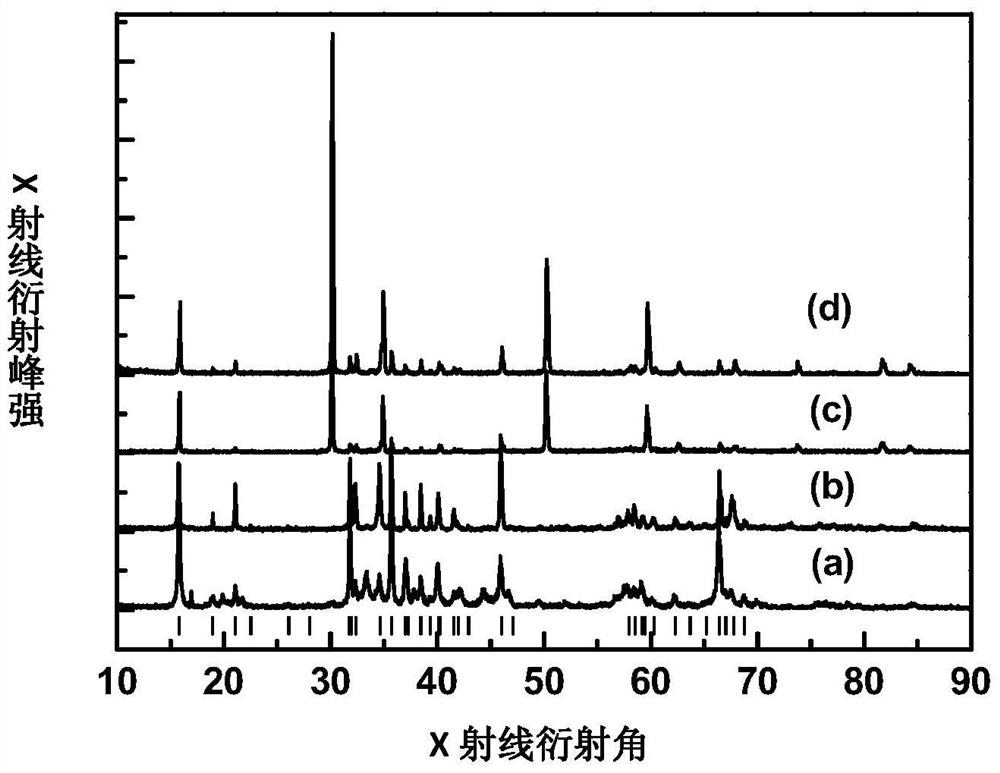

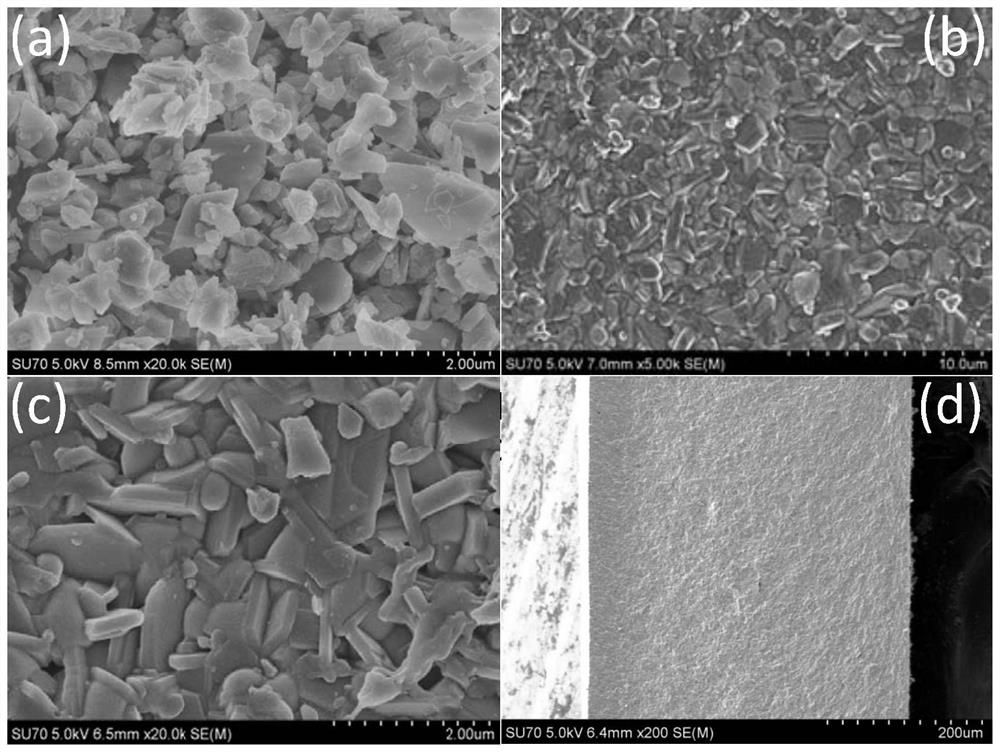

[0047] In this example, β"-Al 2 o 3 The molecular formula of the electrolyte substrate is Na 1.67 Al1 0.67 Mg 0.67 o 17 , its preparation method is as follows:

[0048] (1) Preparation of β"-Al 2 o 3 Powder

[0049] To synthesize 10mol, 6.15kg Na 1.67 Al1 0.67 Mg 0.67 o 17 as an example.

[0050] Weigh 5.4kg of boehmite, 1.44kg of sodium metaaluminate, 395g of magnesium hydroxide, and 10kg of ethanol, mix them in a grinding barrel, use a horizontal sand mill, 2400 rpm, and grind for 5 hours to obtain a uniform slurry material;

[0051] Drying at 45-60°C to remove ethanol, and calcining at 1200°C for 2 hours to obtain a calcined product;

[0052] Grind the calcined product in water or ethanol, add an appropriate amount of binder (PVA or PVP), and spray granulate to obtain β"-Al 2 o 3 Granulated powder.

[0053] (2) Preparation of β"-Al 2 o 3 Strip

[0054] Weigh 1kgβ"-Al 2 o 3 Granulating powder, adding alcohol, PVB, DBP, PEG and tributyl citrate, ball mil...

Embodiment 2

[0058] In this embodiment, in this embodiment, the electrolyte substrate is β"-Al 2 o 3 -YSZ, its preparation method is as follows:

[0059] (1) Preparation of β"-Al 2 o 3 -YSZ powder

[0060] To synthesize 10mol, 6.15kg Na 1.67 Al1 0.67 Mg 0.67 o 17 as an example.

[0061] Weigh 5.4kg of boehmite, 1.44kg of sodium metaaluminate, 395g of magnesium hydroxide, and 10kg of ethanol, mix them in a grinding barrel, use a horizontal sand mill, 2400 rpm, and grind for 5 hours to obtain a uniform slurry Material; dry at 45-60°C to remove ethanol, and calcined at 1200°C for 2h to obtain the calcined product Na 1.67 Al1 0.67 Mg 0.67 o 17 Powder;

[0062] 6kg Na 1.67 Al1 0.67 Mg 0.67 o 17 , 4kg 8YSZ powder is ground in water or ethanol, adding an appropriate amount of binder (PVA or PVP), and spraying granulation to obtain β"-Al 2 o 3 - YSZ granulation powder.

[0063] (2) Preparation of β"-Al 2 o 3 -YSZ Strip

[0064] Weigh 1kgβ"-Al 2 o 3 -YSZ granulation powder,...

Embodiment 3

[0068] In the present embodiment, in the present embodiment, the electrolyte substrate is Mn and Ti doped β "-Al 2 o 3 -YSZ, its preparation method is as follows:

[0069] (1) Preparation of β"-Al doped with Mn and Ti 2 o 3 -YSZ powder

[0070] To synthesize 10mol, 6kg Mn and Ti-doped Na 1.67 Al1 0.67 Mg 0.67 o 17 as an example.

[0071] Weigh boehmite 5.4kg, sodium metaaluminate 1.44kg, magnesium hydroxide 395g, manganese acetate 370g, butyl titanate 68, ethanol 10kg, mix them in a grinding barrel, use a horizontal sand mill, 2400 rev / min, grind for 5h to obtain a homogeneous slurry;

[0072] Drying at 45-60°C to remove ethanol, and calcining at 1200°C for 2 hours to obtain a calcined product;

[0073] 6 kg Mn doped with Ti Na 1.67 Al1 0.67 Mg 0.67 o 17 Grind 4kg 8YSZ powder in water or ethanol, add an appropriate amount of binder (PVA or PVP), and spray granulate to obtain Mn and Ti doped β"-Al 2 o 3 - YSZ granulation powder.

[0074] (2) Preparation of Mn a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com