Needle and thread coil

A needle and thread roll and needle and thread technology, applied in the field of needle and thread, can solve the problems of not fast, the end is not strong enough, and the threading is difficult, and achieves the effect of simple and scientific structure, convenient collection and storage, and great promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

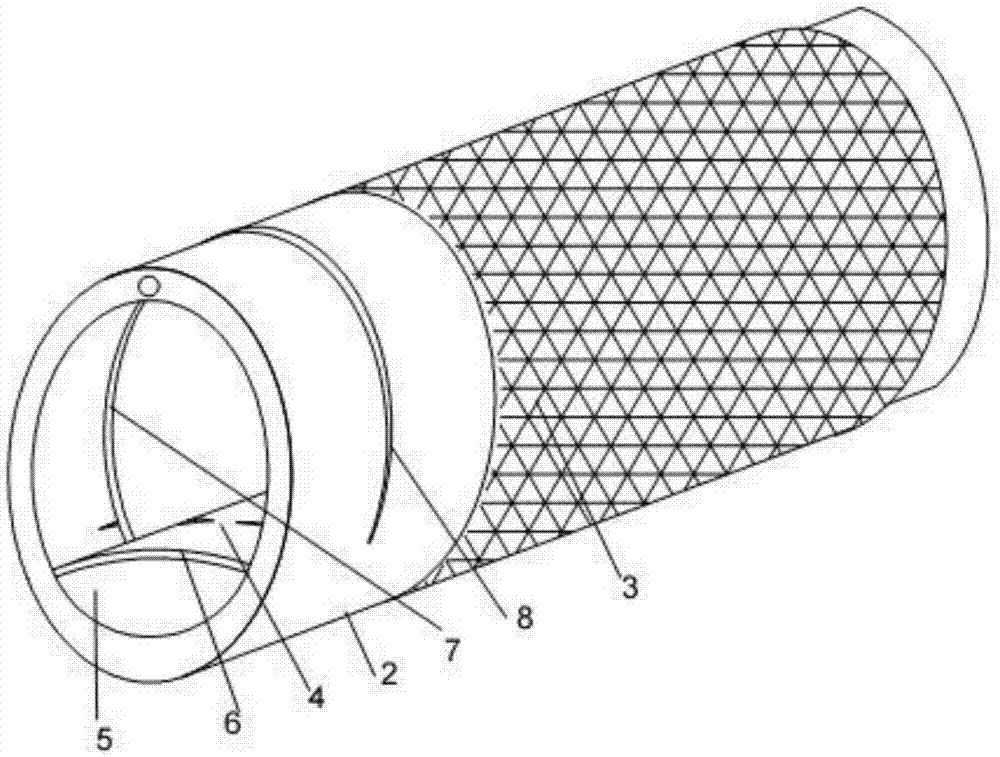

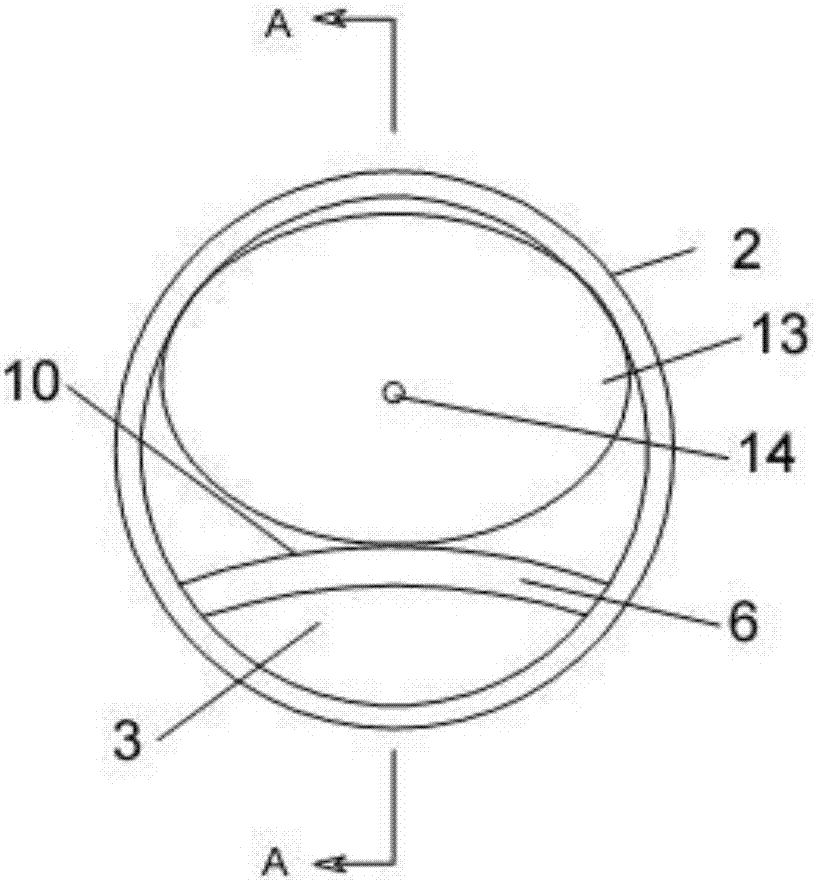

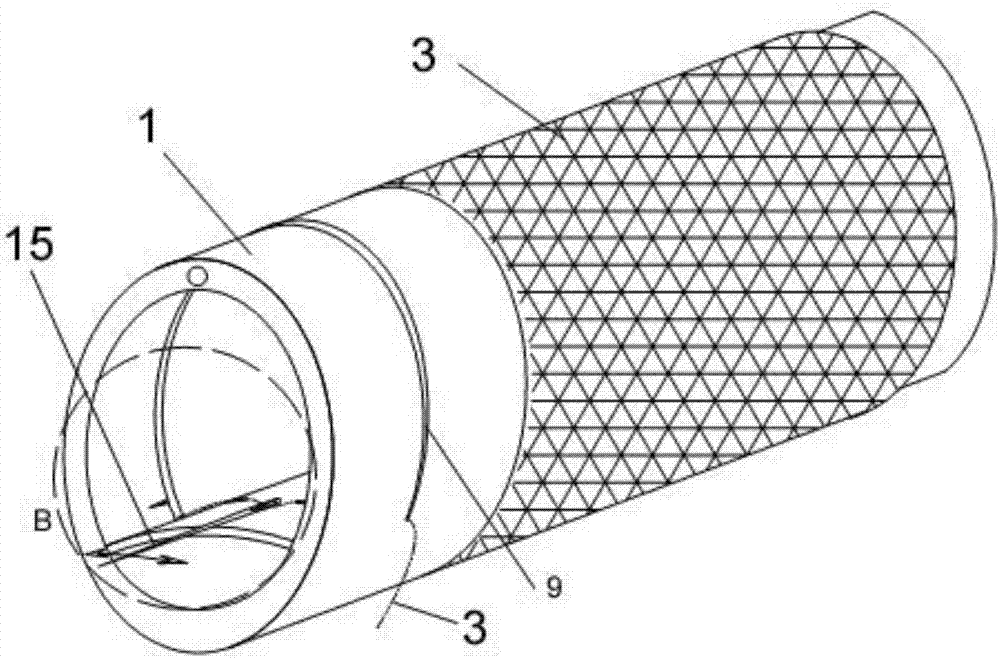

[0021] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0022] see Figure 1 to Figure 6 The needlework roll 1 includes a hollow paper tube 2, and a needle thread 3 wound layer by layer around the outer periphery of the hollow paper tube 2, and a plastic block 5 adhered to one side of the inner wall of the hollow paper tube 2, and the surface of the plastic block 5 is an upwardly arched arc Surface 10, curved surface 10 is compounded with a soft leather layer 6 with a thickness of 2 mm to 3 mm; the surface of the soft leather layer 6 is provided with a horizontal shallow groove 4 that provides positioning and limiting functions for the needle thread 3, and the horizontal shallow groove 4 is shallow in the middle and deep on both sides. ; The hollow paper tube 2 is provided with a semi-annular slot 9 above the horizontal shallow groove 4 for the needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com