Method for measuring peeling torque of conical friction pair

A measurement method and technology of friction pairs, applied in the direction of force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of inaccurate data collection, difficulty in measuring the peeling torque of conical friction pairs, etc., and achieve accurate measurement data collection, Accurate torque data and smooth torque increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] The conical friction pair used in this embodiment is the tested workpiece composed of the tested piece a3 and the tested piece b7.

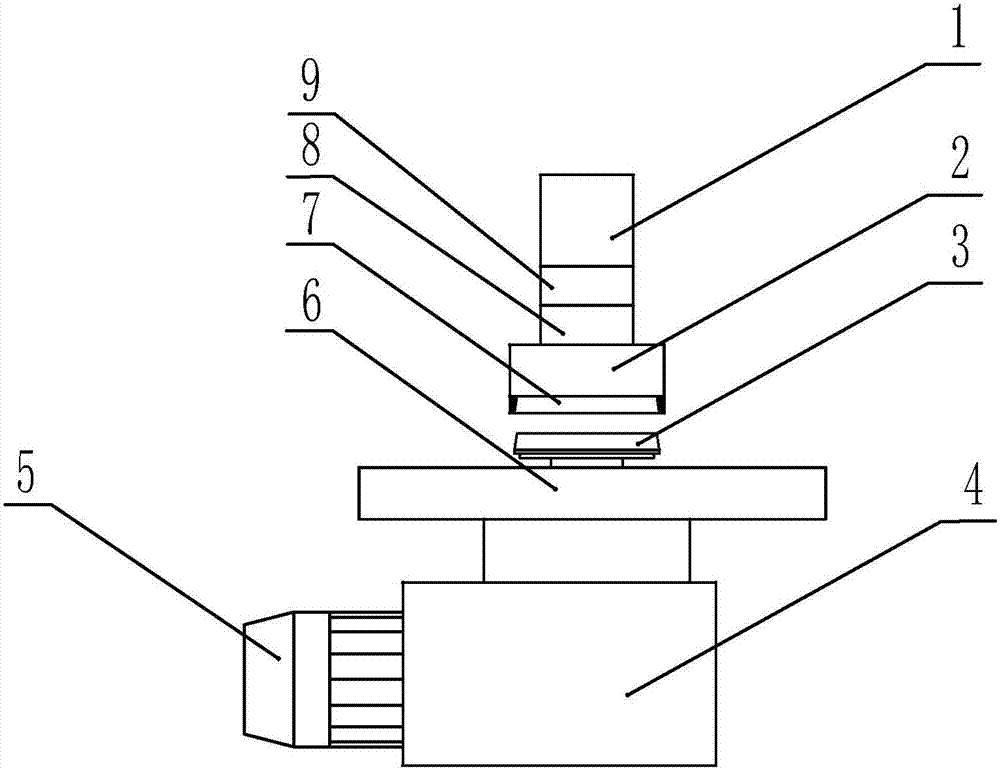

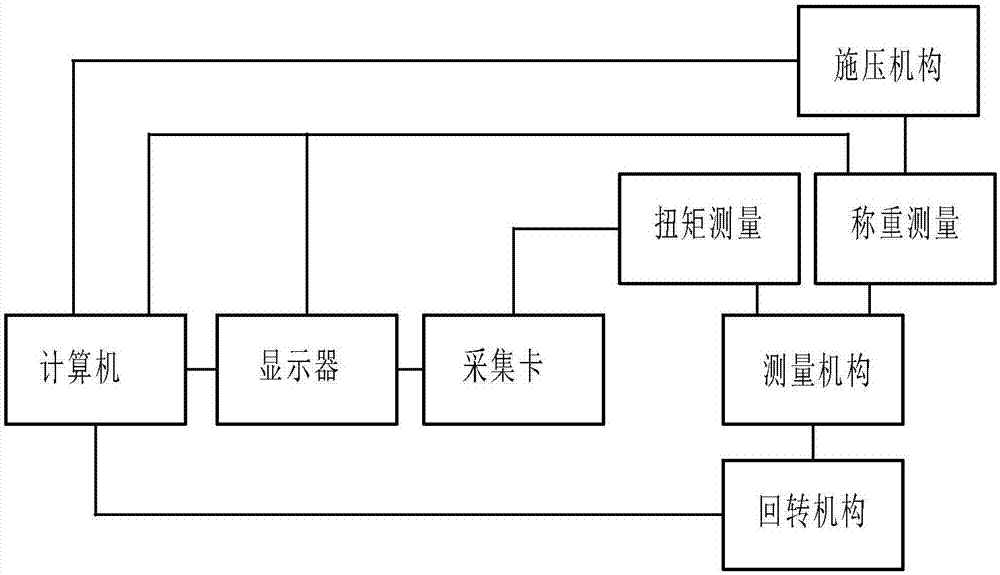

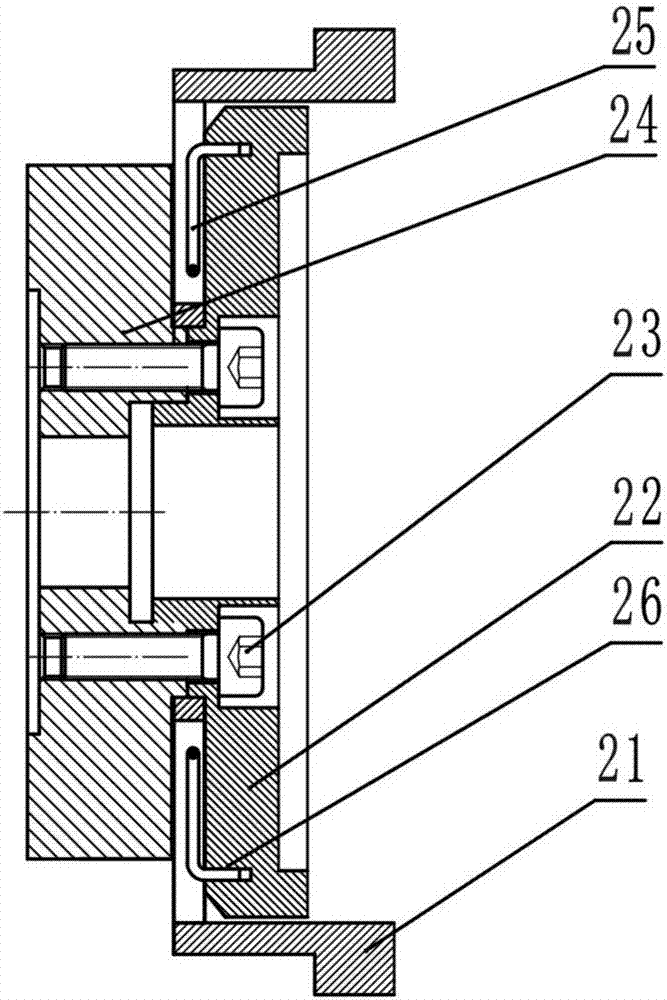

[0027] Such as figure 1 As shown, the conical friction pair measurement device used in this embodiment is composed of a pressure applying mechanism, a measuring mechanism, a rotary buffer mechanism 2 and a rotary mechanism. The pressing mechanism mainly includes a pressing element 1 which moves in a linear direction and transmits power, and a servo motor driving part (not shown in the figure). The measuring mechanism mainly includes a load cell 9 and a torque sensor 8 . The pressure applying element 1, the load cell 9, the torque sensor 8 and the rotary buffer mechanism 2 are connected through a conventional connecting seat that matches with each element, and are driven by a servo motor to move up and down. The rotary mechanism inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com