A fully automatic battery packaging equipment

A kind of packaging equipment and fully automatic technology, which is applied in the direction of manufacturing primary battery equipment, primary batteries, battery assembly machines, etc., can solve the problems of high labor cost and low work efficiency, and achieve the effect of high automation and novel structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described below in conjunction with specific embodiments.

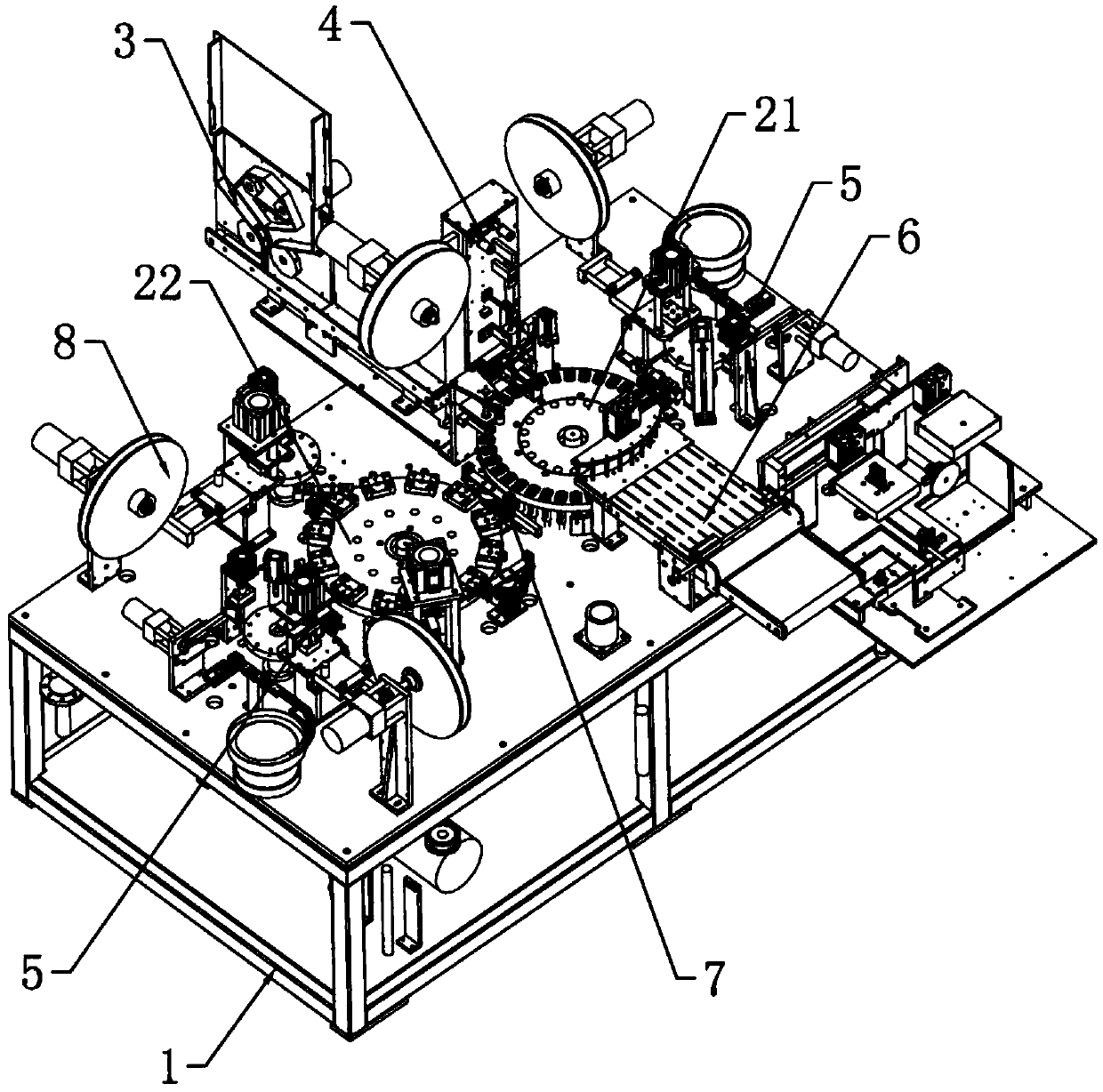

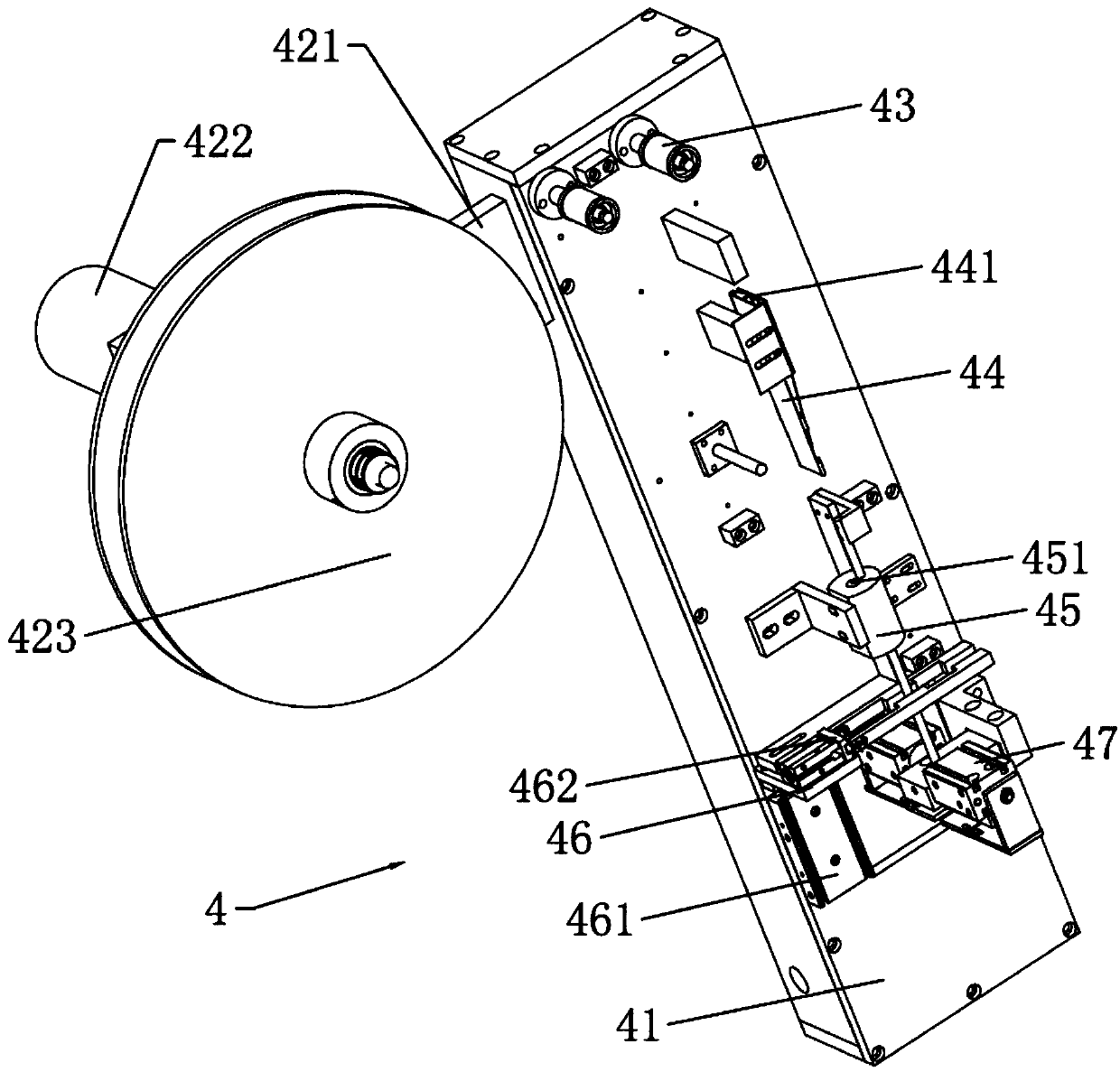

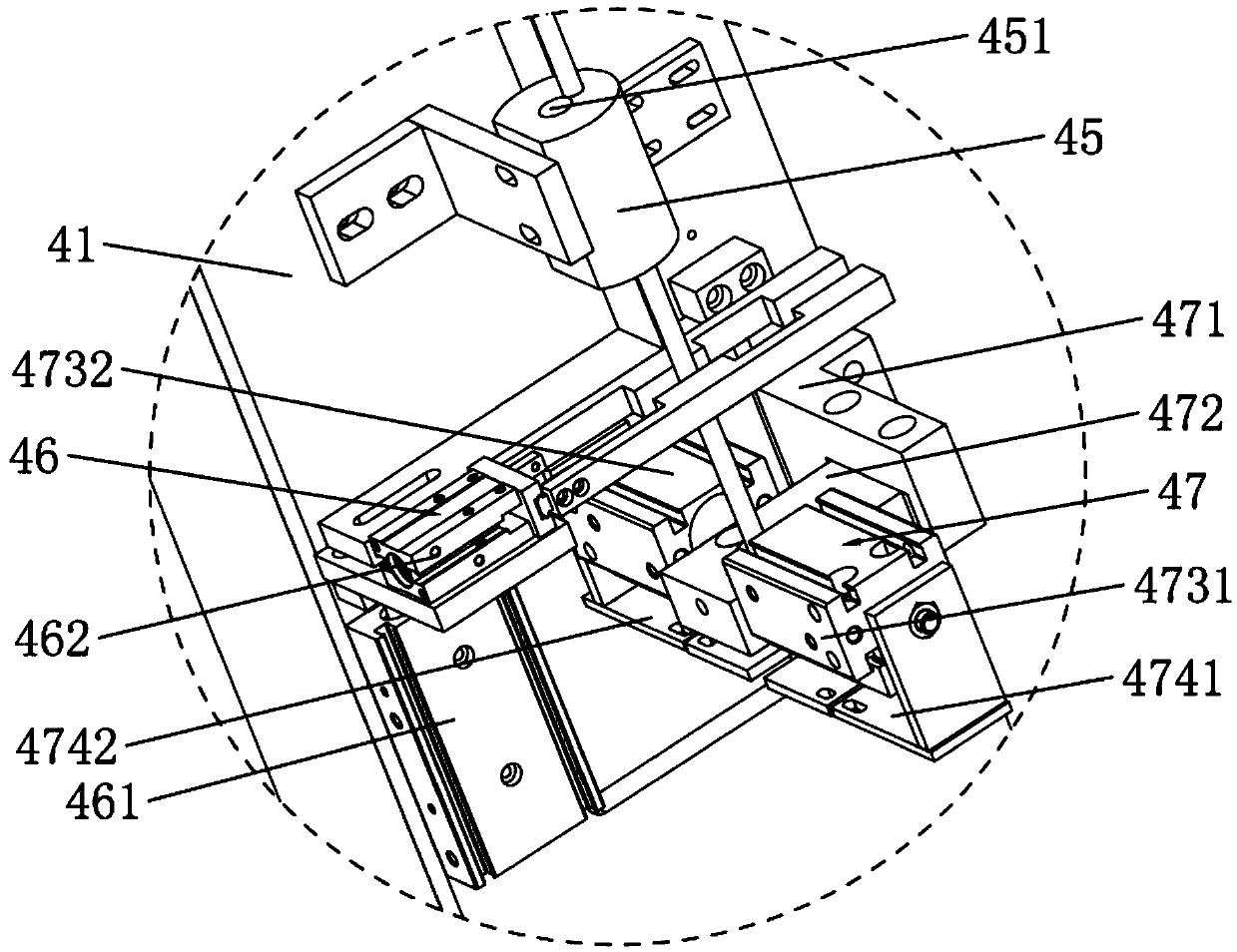

[0069] like figure 1 As shown, a fully automatic battery packaging equipment includes a frame 1, and the upper end of the frame 1 can be relatively intermittently rotated to be equipped with a first turntable 21 and a second turntable 22 respectively driven by a divider. The turntable 21 and the second turntable 22 are arranged at intervals, and the upper end of the frame 1 is installed on the side of the first turntable 21. The battery case feeder 3 and the diaphragm paper feeding mechanism are arranged at intervals along the rotation direction of the first turntable 21. 4. The electrode cover feeding mechanism 5, the battery particle feeding mechanism 6, the upper end of the frame 1 is equipped with an intermediate transfer manipulator 7 between the first turntable 21 and the second turntable 22, the upper end of the frame 1 is placed between the second turntable 22 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com