Double-header harvester with crawling ladder and capability of uniformly crushing straws

A straw crushing and harvester technology, applied in harvesters, cutters, cutting equipment, etc., can solve the problems of affecting the threshing effect, large grain loss, large machine damage, etc., to improve the threshing effect, reduce machine loss, reduce The effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

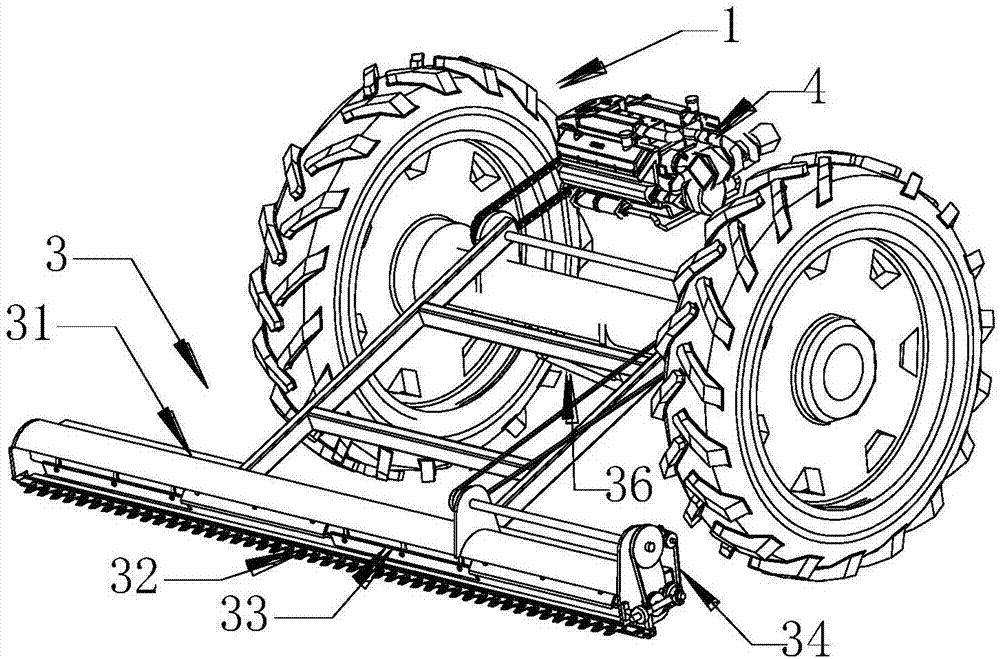

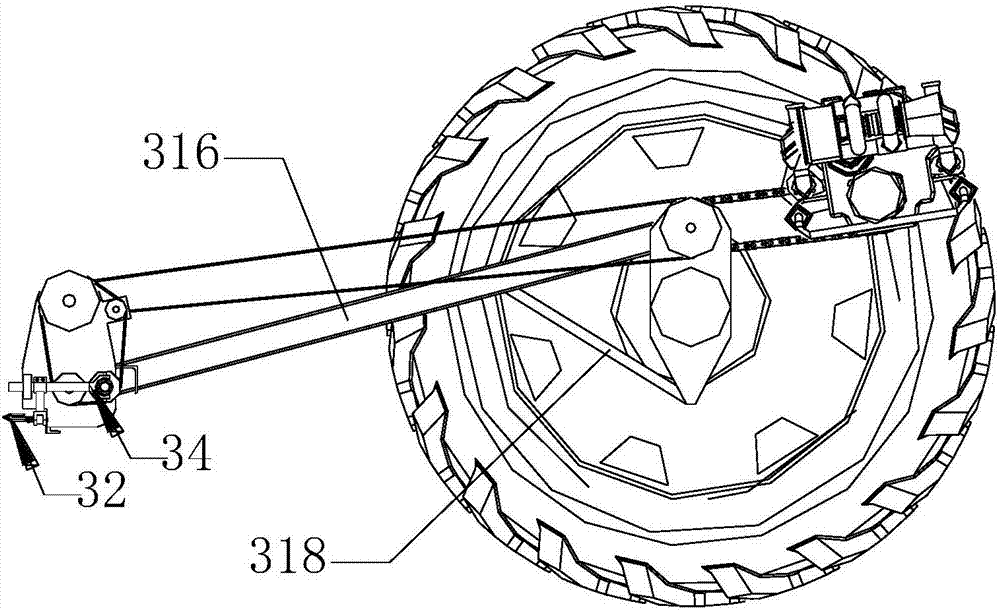

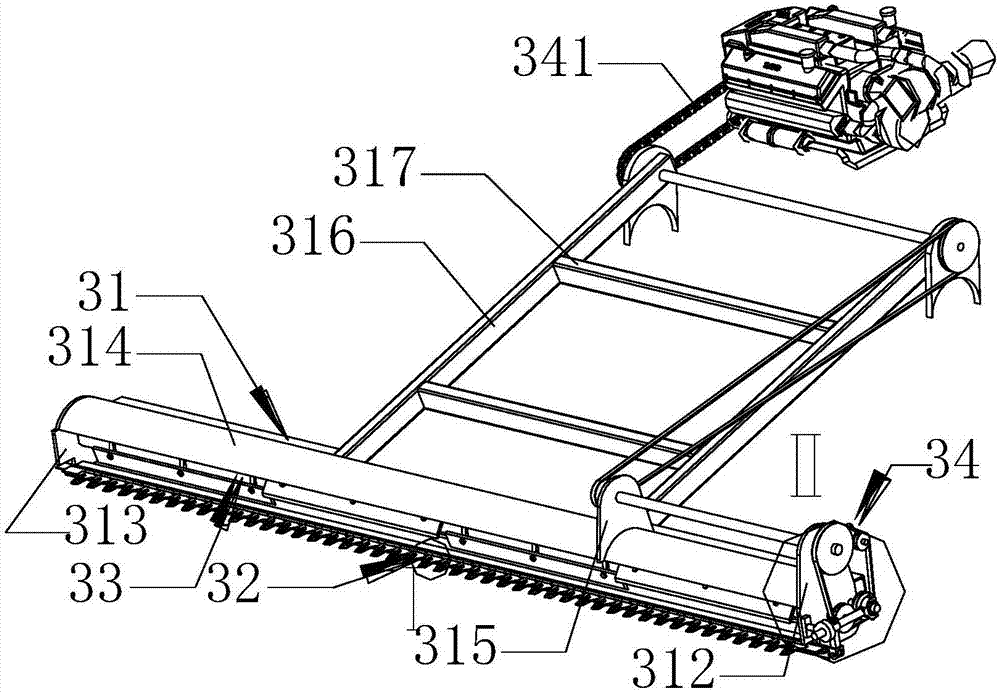

[0042] Such as figure 1 , 14 As shown in 15, the harvester with double headers with ladder stalks crushed evenly includes an upper header 2 and a lower header 3, the upper header 2 is hinged on the front bridge of the harvester, and the lower header 3 is fixed Welded on the front axle of the harvester and located below the upper header 2, the upper header 2 includes the upper header main frame 21, the upper cutting mechanism 22, the auger 23, the reel 24 and the upper header lifting mechanism 25, the lower cutting The table includes the main frame of the lower header 31, the lower cutting mechanism 32, the stalk crushing mechanism 33 and the transmission mechanism 34;

[0043] Such as Figure 14 , 15 As shown, the upper header main frame 21 includes an upper header hopper, and a reel support rod is respectively arranged on both sides of the upper header hopper top, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com