Constant-current frequency-conversion micro-irrigation system

A technology of micro-irrigation and frequency converter, which is applied in the field of agricultural irrigation, can solve the problems of low pressure, various hydraulic losses of pipelines, and affecting the quality of micro-irrigation water, so as to achieve the effect of improving irrigation water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

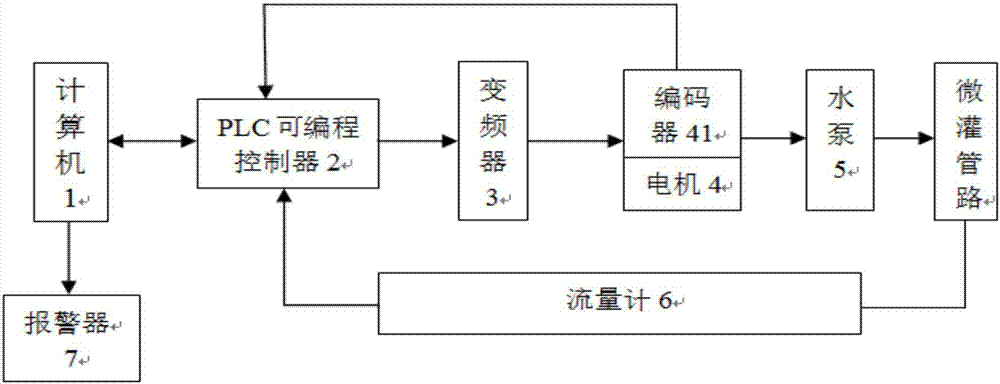

[0022] The micro-irrigation frequency conversion control system of this embodiment is as follows: figure 1 As shown, computer 1 for terminal control, PLC programmable controller 2, frequency converter 3, motor 4, water pump 5, encoder 41 arranged on motor 4, flow meter 6 arranged in front of the micro-irrigation system, alarm When the micro-irrigation system in operation is blocked (that is, the flow rate is less than the set lower limit), the computer program can immediately identify the alarm and stop the water pump to prevent explosion.

[0023] The PLC programmable controller 2 is electrically connected bidirectionally with the communication port of the computer 1 through its communication port; the control terminal of the frequency converter 3 is electrically connected with the corresponding output port of the PLC programmable controller 2; The power supply end is electrically connected; the output end of the flowmeter 6 and the output end of the encoder 41 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com