The Technology of Using Sulfuric Acid-Ethanol to Extract Bamboo Leaf Pepper

A technology of ethanol extraction and bamboo leaf pepper, applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, non-central analgesics, etc., to achieve the effects of saving costs, improving utilization rates, and increasing ointment yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

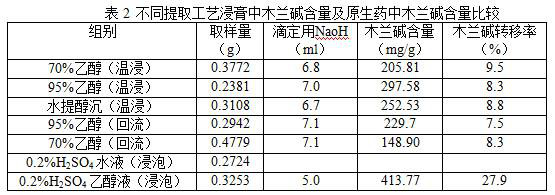

[0022] Crush the bamboo leaf pepper into coarse grains. Take 100g of bamboo leaf pepper coarse grains, add 0.2% H 2 SO 4 Ethanol, soaked for 24 hours, filtered; the dregs were extracted once more by the same process, filtered; the two filtrates were combined, neutralized with concentrated NaOH until neutral, and concentrated under reduced pressure at 60°C to obtain the extract of bamboo leaf pepper. The ointment yield was 13.04%; the content of magnolanine was 413.77mg / g; the transfer rate of magnolanine was 27.9%.

Embodiment 2

[0024] Crush the bamboo leaf pepper into coarse grains. Take 100g of bamboo leaf pepper coarse grains, add 0.1% H 2 SO 4 Ethanol, soaked for 24 hours, filtered; the dregs were extracted once more by the same process, filtered; the two filtrates were combined, neutralized with concentrated NaOH until neutral, and concentrated under reduced pressure at 60°C to obtain the extract of bamboo leaf pepper. The cream yield was 12.98%; the content of magnolanine was 412.05mg / g; the transfer rate of magnolanine was 27.7%.

Embodiment 3

[0026] Crush the bamboo leaf pepper into coarse grains. Take 100g of bamboo leaf pepper coarse grains, add 0.15% H 2 SO 4 Ethanol, soaked for 24 hours, filtered; the dregs were extracted once more by the same process, filtered; the two filtrates were combined, neutralized with concentrated NaOH until neutral, and concentrated under reduced pressure at 60°C to obtain the extract of bamboo leaf pepper. The yield of ointment was 13.01%; the content of magnolanine was 413.04mg / g; the transfer rate of magnolanine was 28.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com