Preparation method of formula granules of wined herba citsanches

A technology of formula granules and cistanche deserticola is applied in the field of preparation of formula granules of cistanche deserticola, which can solve the problems of production efficiency, powder yield and product quality at the same time, and achieves saving preparation cost, efficient production efficiency, and improving output. The effect of paste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

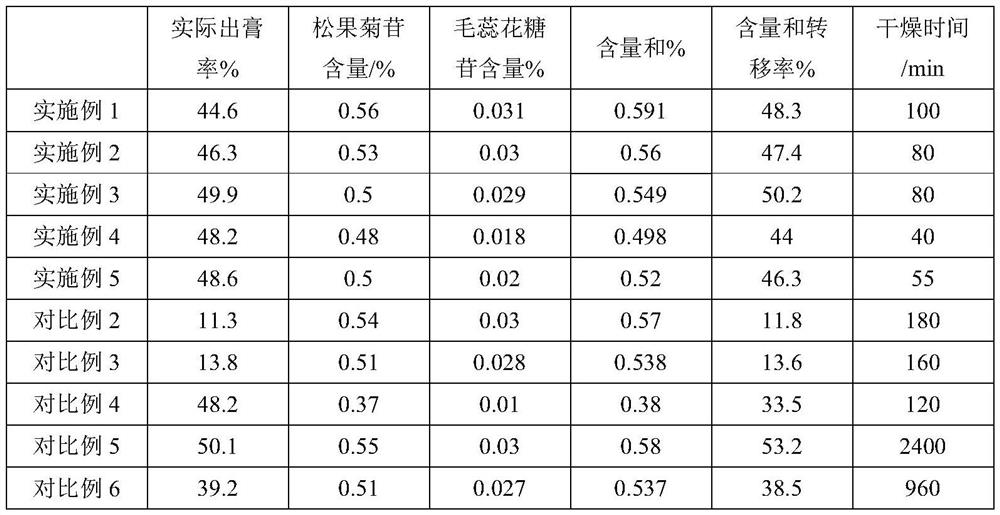

Embodiment 1

[0026] A preparation method of wine cistanche formula granules, the specific process is as follows:

[0027] Extraction: Take 120kg of decoction pieces of cistanche cistanche, put them into an extraction tank, add drinking water with a volume of 12L / kg of decoction pieces, heat to boiling and extract for 1.5h, filter; then add drinking water with a volume of 10L / kg of decoction pieces, heat and boil for 1.5h, Filter, combine the two extracts, and store in a storage tank.

[0028] Concentration: Concentrate under reduced pressure at a vacuum degree of -0.08Mpa and a temperature of 70°C to a clear paste (60°C) with a relative density of 1.20±0.05.

[0029] Drying: Add dextrin as an auxiliary material to the clear paste, the weight ratio of cistanche cistanche decoction pieces and auxiliary materials is 100:5, mix evenly, stir and heat to 85°C, decompression belt drying, feeding speed: 80ml / min, temperature in the first section: 60 ℃, the temperature of the second section: 60°C,...

Embodiment 2

[0032] A preparation method of wine cistanche formula granules, the specific process is as follows:

[0033] Extraction: Take 120kg of decoction pieces of cistanche cistanche, put them into an extraction tank, add drinking water with a volume of 12L / kg of decoction pieces, heat to boiling and extract for 1.5h, filter; then add drinking water with a volume of 10L / kg of decoction pieces, heat and boil for 1.5h, Filter, combine the two extracts, and store in a storage tank.

[0034] Concentration: Concentrate under reduced pressure at a vacuum degree of -0.07Mpa and a temperature of 70°C to a clear paste (60°C) with a relative density of 1.20±0.05.

[0035] Drying: Add dextrin as an auxiliary material to the clear paste, the weight ratio of cistanche decoction pieces and auxiliary materials is 100:5, mix well, mix evenly, stir and heat to 80°C, decompression belt drying, feeding speed: 60ml / min, one section Temperature: 80°C, second section temperature: 80°C, third section tempe...

Embodiment 3

[0038] A preparation method of wine cistanche formula granules, the specific process is as follows:

[0039] Extraction: Take 120kg of decoction pieces of cistanche cistanche, put them into an extraction tank, add drinking water with a volume of 12L / kg of decoction pieces, heat to boiling and extract for 1.5h, filter; then add drinking water with a volume of 10L / kg of decoction pieces, heat and boil for 1.5h, Filter, combine the two extracts, and store in a storage tank.

[0040]Concentration: Concentrate under reduced pressure at a vacuum degree of -0.09Mpa and a temperature of 70°C to a clear paste (60°C) with a relative density of 1.20±0.05.

[0041] Drying: Add dextrin as an auxiliary material to the clear paste, the weight ratio of cistanche cistanche decoction pieces and auxiliary materials is 100:10, mix evenly, stir and heat to 90°C, decompression belt drying, feeding speed: 90ml / min, first-section temperature: 90 ℃, the temperature of the second section: 90°C, the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com