Spare wheel up-down regulator assembly with steel wire rope

A technology of wire rope and lifter, which is applied in the field of car spare tire lifting device, can solve the problems of complex transmission structure and high failure rate, and achieve the effects of improved manufacturing process, high torsional strength and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

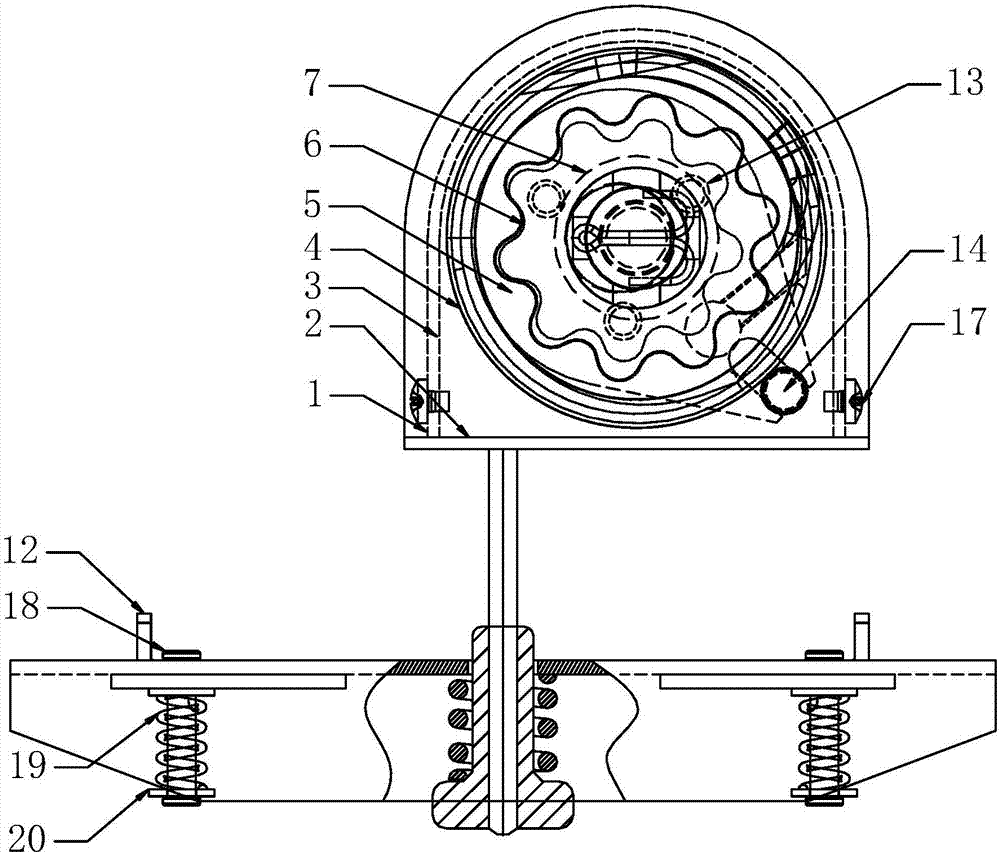

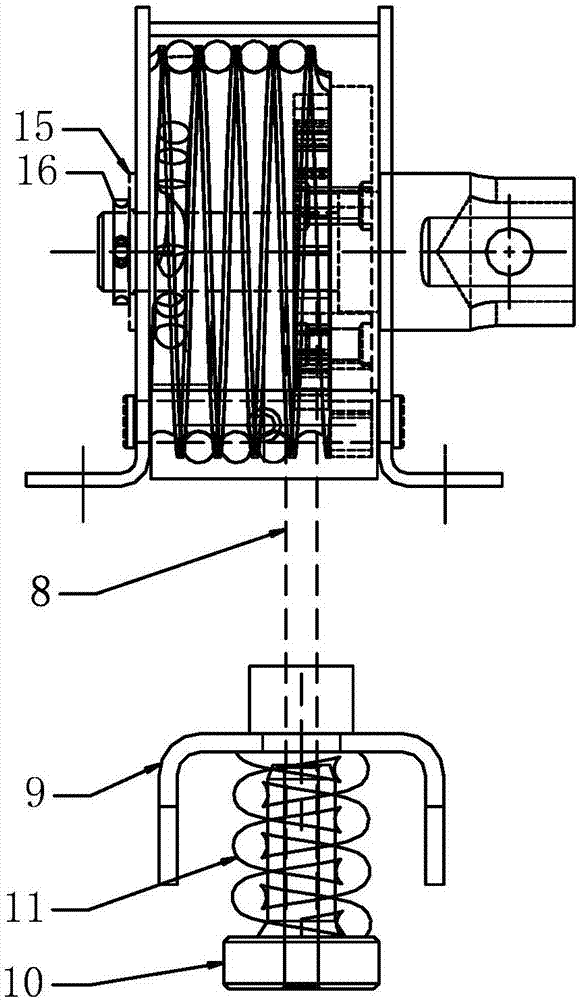

[0023] refer to Figure 1-5 , a wire rope spare tire lifter assembly, comprising a housing 1, the outer side of the housing 1 is fixedly connected with a protective cover 2 through screws 17, the side of the protective cover 2 is fixedly connected with a side blocking piece 3, and the housing 1 is movable and socketed There is an eccentric shaft 7, the guiding iron 5 is sleeved on the eccentric shaft 7, the guiding iron 5 and the ratchet 6 are riveted through the first rivet 13, the ratchet 6 meshes with the winding gear 4, and the winding gear 4 is wound with a wire rope 8, The wire rope 8 is fixedly sleeved with a hanger 9, and the end of the wire rope 8 is fixedly connected with a lock head 10. The lock head 10 and the hanger 9 are equipped with a first spring body 11, and the first spring body 11 is sleeved on the outside of the wire rope 8. The frame 9 is symmetrically equipped with two clips 12, the clips 12 are fixed on the hanger 10 by the third rivet 18, the outside o...

Embodiment 2

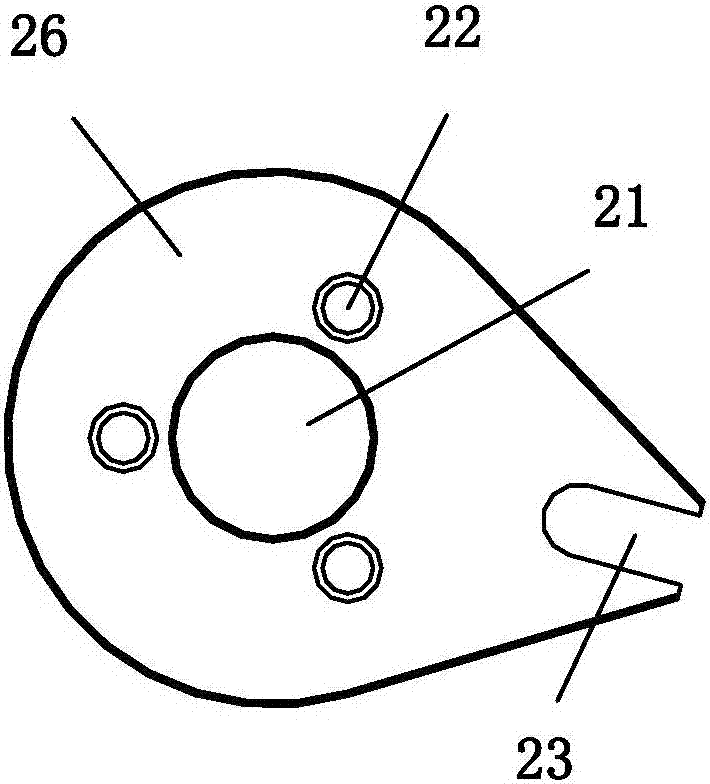

[0027] refer to Figure 6 , this embodiment is an improvement on the structure of the hanger on the basis of Embodiment 1. The shape of the clamping plate 12 is hexagonal, and the clamping plate 12 and the hanger 9 are movably connected by a rotating shaft 25 , and the rotating shaft 25 and the clamping plate 12 are arranged eccentrically. In this embodiment, the distance between the two clamping plates 12 can be adjusted by rotating the clamping plates 12 and using the structure that the clamping plates 12 rotate eccentrically around the rotating shaft 25 , so as to adapt to wheel hubs of different sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com