Rotor for synchronous reluctance motor

A synchronous reluctance motor and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, electrical components, etc., can solve the problems of motor magnetic flux leakage, high temperature demagnetization of permanent magnet motor, low material utilization rate, etc., and improve the air gap. Magnetic density and power density, the effect of increasing the magnetic flux per pole, and increasing the speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

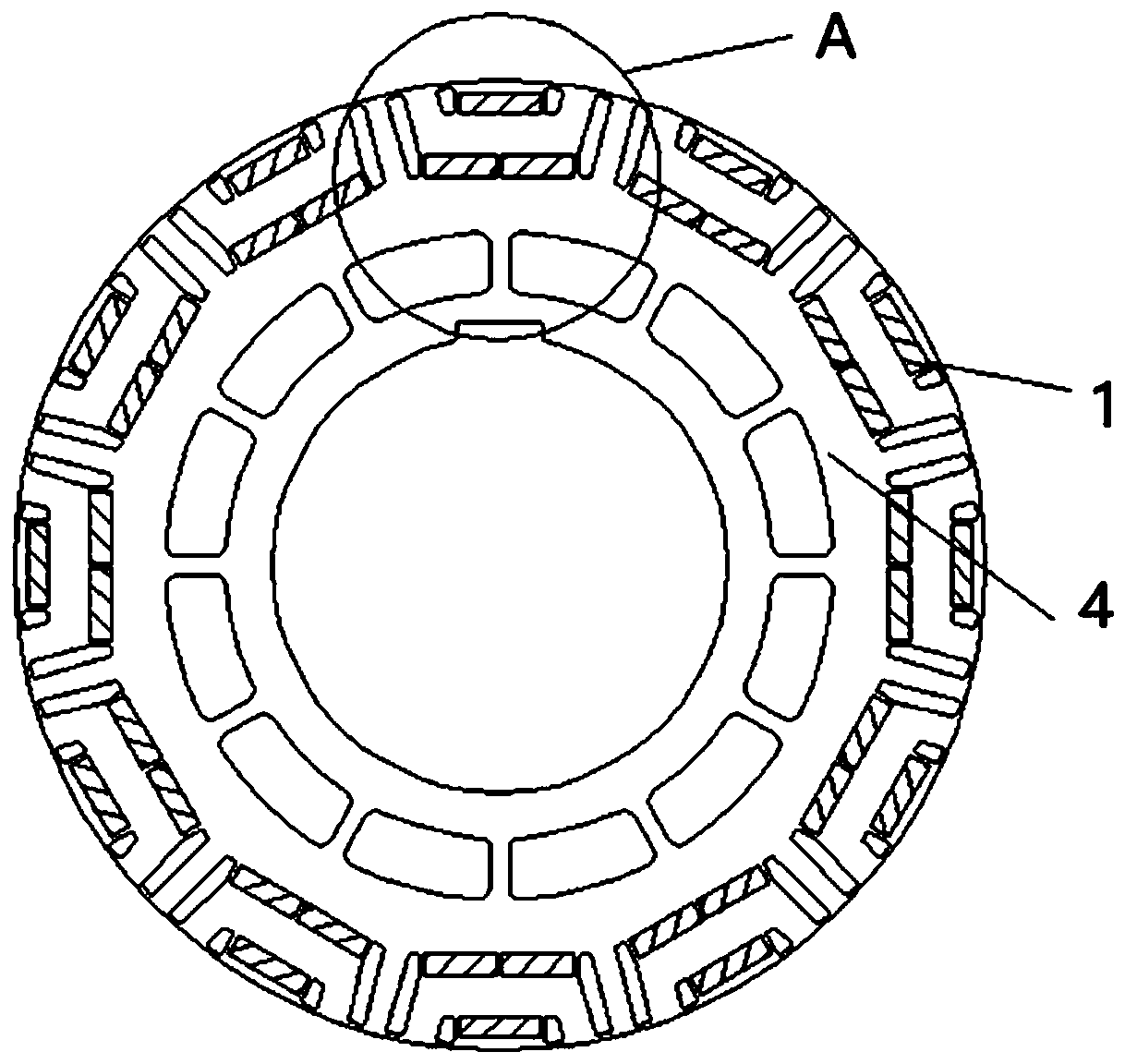

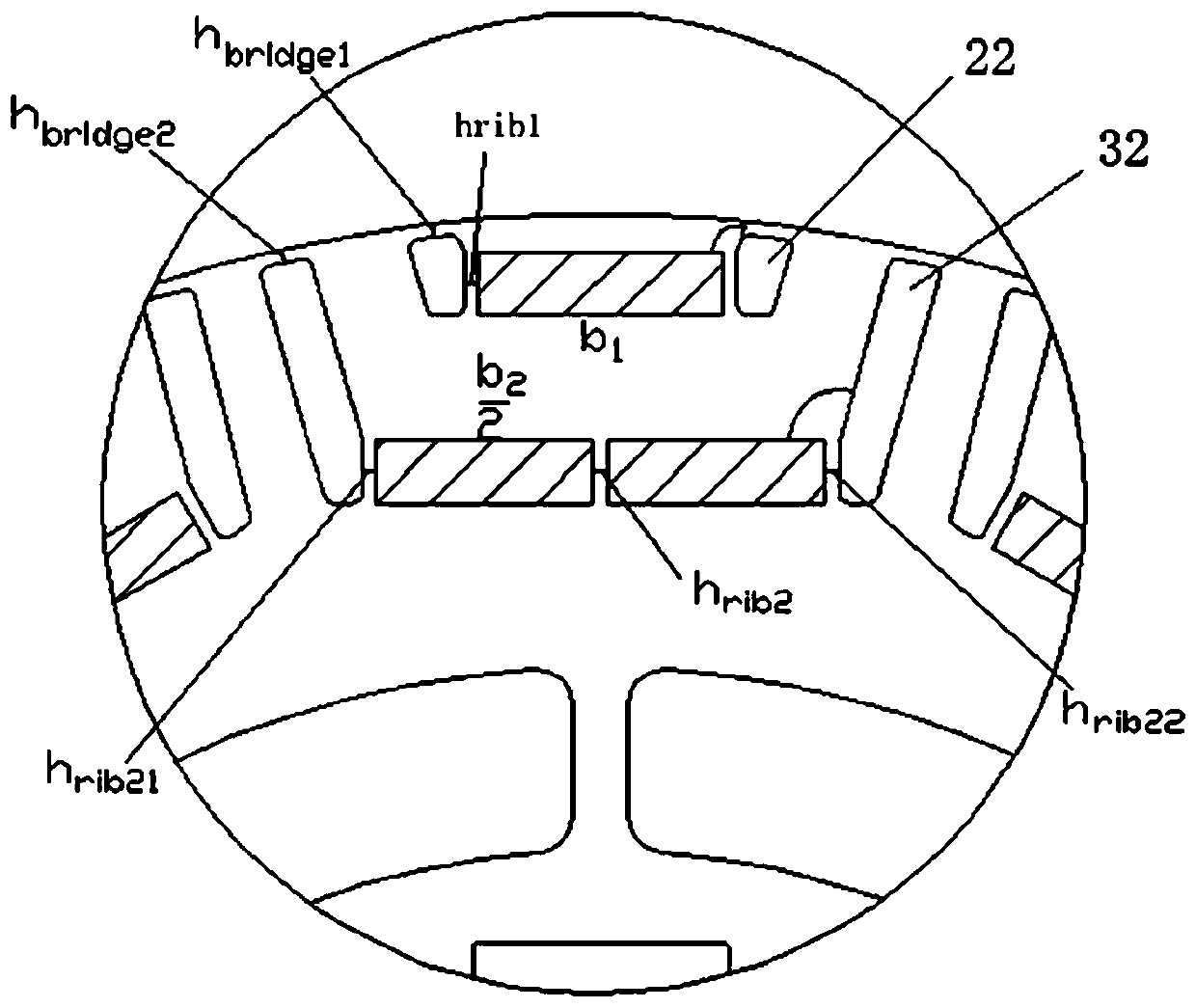

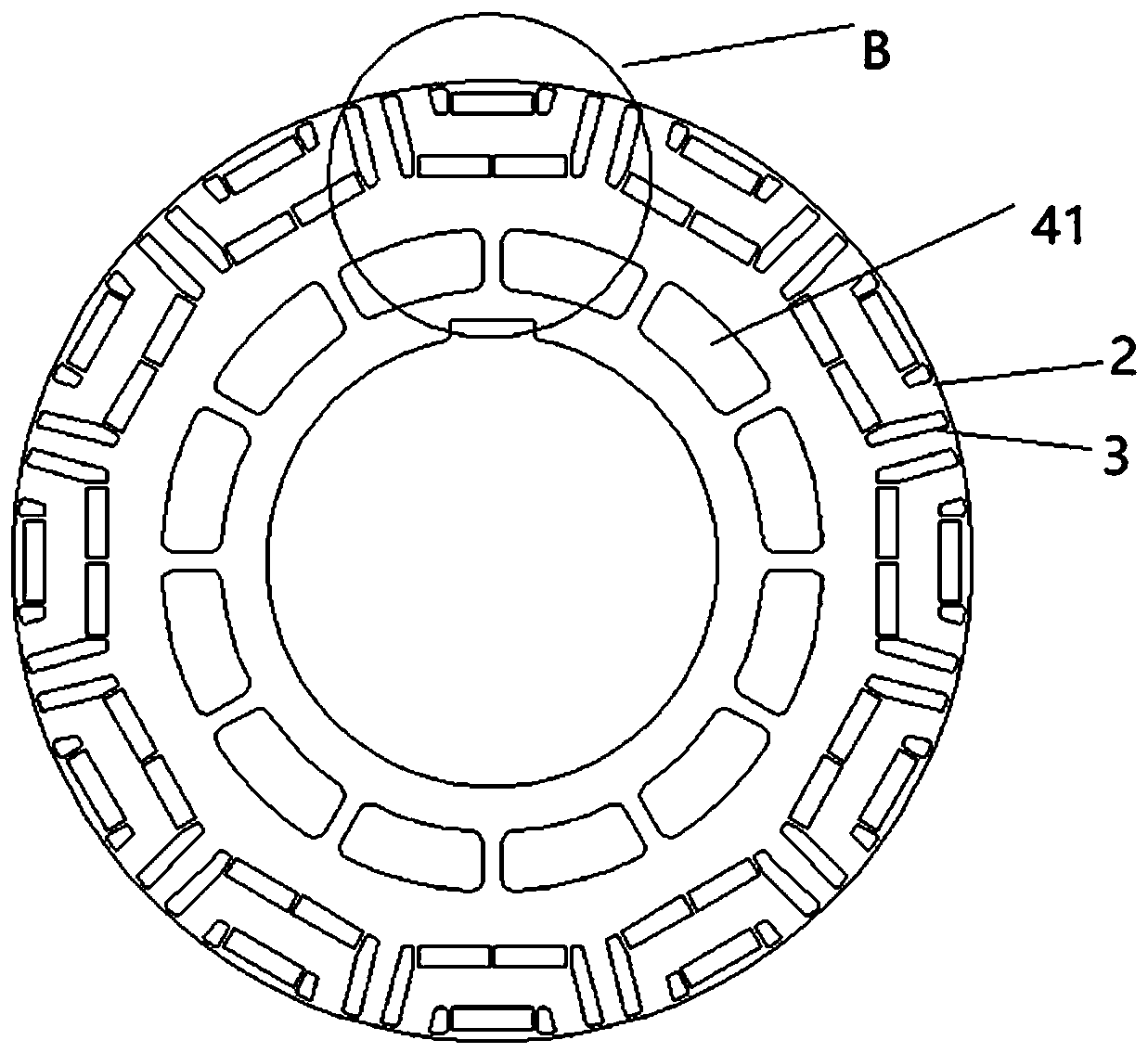

[0031] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0032] First, some abbreviations or professional terms involved in the present invention are defined:

[0033] Reluctance motor: It is a continuous running electrical transmission device. Its structure and working principle are very different from traditional AC and DC motors. It does not rely on the interaction of the magnetic field generated by the stator and rotor winding currents to generate torque, but relies on the "minimum reluctance principle" to generate torque.

[0034] Orthogonal axis: The quadratu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com