Intelligent weighing method for travelling crane

An intelligent weighing and weighing technology is applied in the fields of iron and steel metallurgy measurement, intelligent driving weighing, and automatic driving measurement of the weight of objects to be hoisted. , Improve production efficiency and measurement accuracy, and increase the effect of software application functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

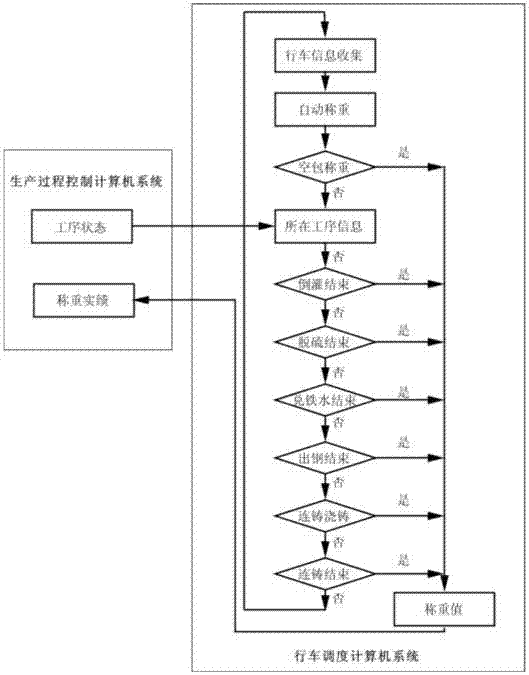

[0018] refer to figure 1 , a kind of driving intelligent weighing method that the present invention provides, comprises the following steps:

[0019] A driving intelligent weighing method, the method comprises the steps of:

[0020] 1) Acquisition of driving data, automatic collection of driving operation parameters through the driving dispatching computer system;

[0021] 2) Judgment of the state of crane and hoisting, the computer system of traffic dispatching judges the position of the driving process and the status of hoisting according to the operating range of the traffic and the position of the main and auxiliary hooks of the crane from the girder of the crane; the computer system of traffic dispatching collects data from the production process control computer through text communication The production information of the system controls the driving operation;

[0022] 3) Weighing the hoisted objects on the driving train. The hoisted objects are vacated at a certain he...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap