Preparation technology of medicinal water-tolerant double-first-class medium borosilicate glass ampoule bottle

A technology of borosilicate glass and preparation process, which is applied in glass manufacturing equipment, manufacturing tools, glass forming, etc. It can solve the problems of insufficient water resistance and peeling off of borosilicate ampoule bottles, and achieve the elimination of safety hazards and simple equipment process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

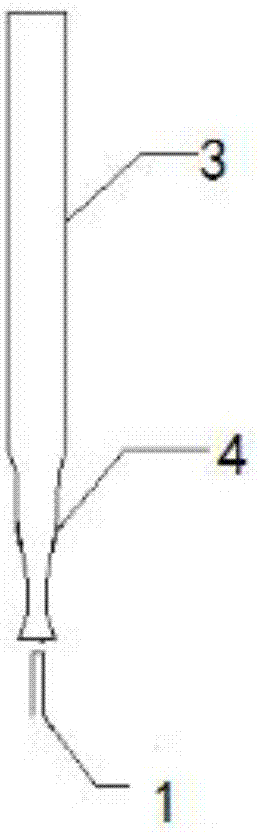

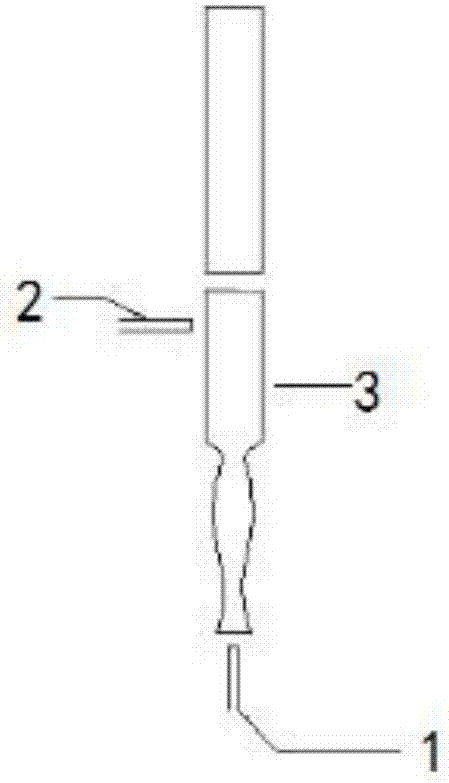

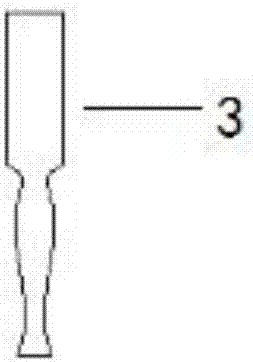

[0021] to combine figure 1 , figure 2 and image 3 Describe in detail by this embodiment:

[0022] A preparation process for medicinal water-resistant double-grade medium borosilicate glass ampoules, using a vertical ampoule production line, including the following steps:

[0023] (1) Upper tube: The vertical ampoule production host consists of several stations evenly distributed on the same circumference, revolving around the axis, and the stations themselves rotate on their own, and at the same time there are two chucks above and below each station , the glass tube is clamped between the first chuck at the top and the second chuck at the bottom, and the second chuck moves up and down through the transmission of friction wheels. For soaking and cleaning, the third chuck below holds the first thin tube 1, and the fourth chuck above holds the second thin tube 2, and both the first thin tube 1 and the second thin tube 2 are connected automatically. Air blowing device, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com