Self-reset precast assembled bridge pier with internally-installed prestress FRP rebars and construction method for self-reset precast assembled bridge pier

A prefabricated assembly and prestressed technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of unseen and difficult to carry out stretching construction, etc., to achieve a wide range of applications, save materials, and improve self-resetting ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

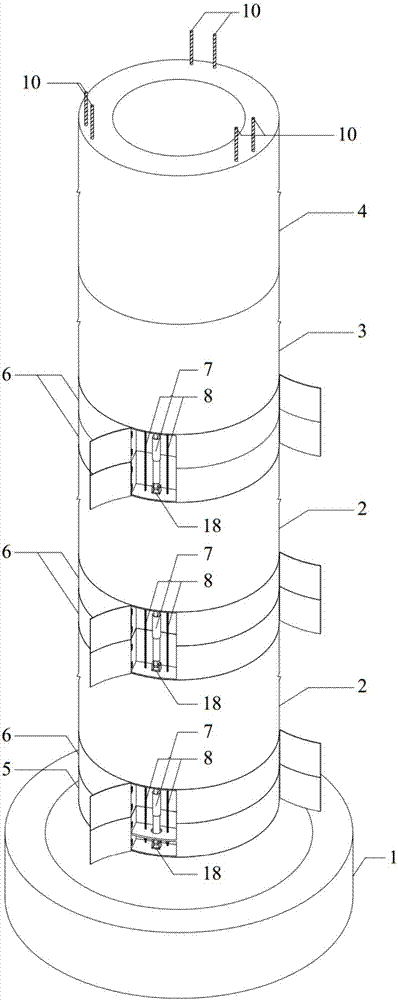

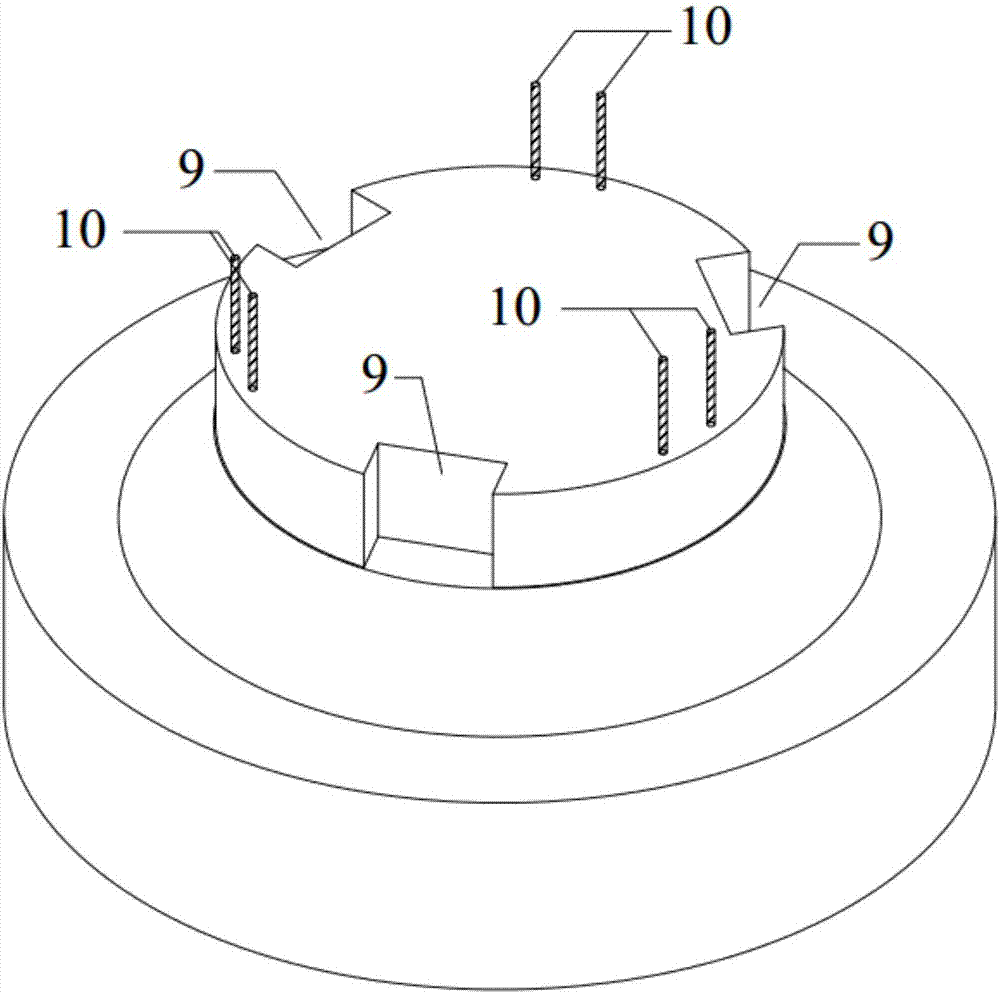

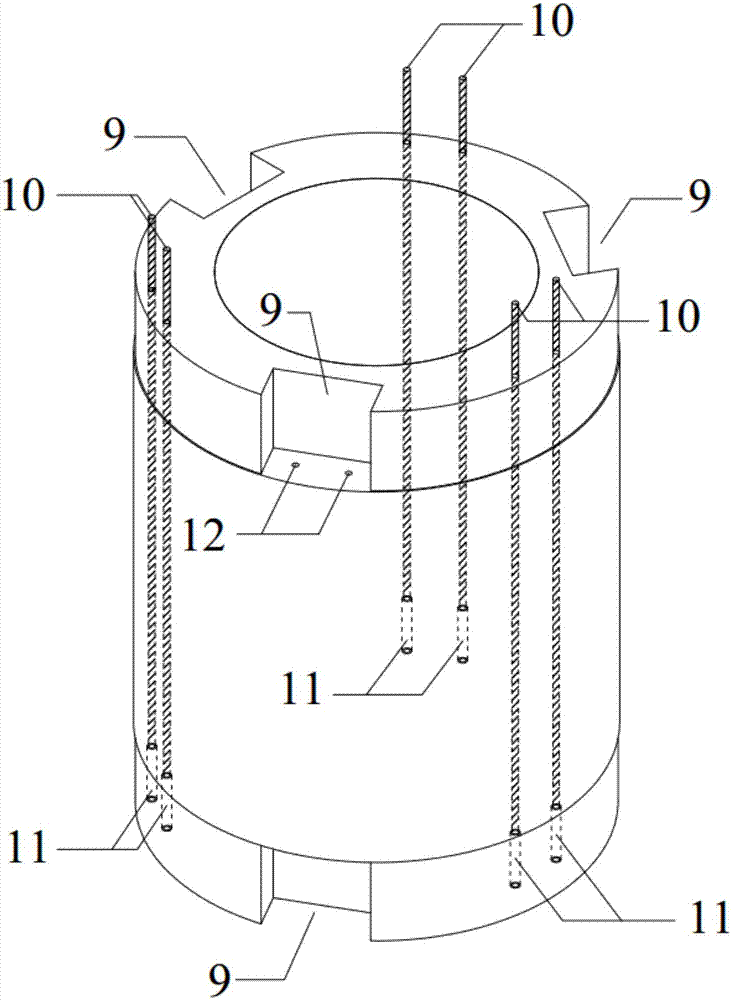

[0065] The present invention will be further described below in conjunction with embodiment and accompanying drawing. The present invention is a self-resetting prefabricated assembled bridge pier with built-in prestressed FRP tendons, including a structural main body composed of cap 1, swing segment 2, transition segment 3 and ordinary segment 4, and the end of cap 1 is provided with " [”-shaped groove a9 and nested in the single-wall steel sleeve 5, the two ends of the swing segment 2 and the lower end of the transition segment 3 are provided with a []-shaped groove a9 and nested in the double-wall steel sleeve 6 1. The upper end of the transition section 3 and the two ends of the ordinary section 4 are not specially treated in the present invention. A viscous damper 7 is installed in the "[" type groove a9, and a viscous damper 7 is installed between the cap 1 and the transition section 3. There is a prestressing system, and the prestressing system includes prestressing FRP ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com