Construction method for maintenance of vertical concrete member

A construction method and concrete technology, which is applied in the construction of buildings, the processing of building materials, construction, etc., can solve the problems of large water consumption and non-compliance with green construction requirements, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

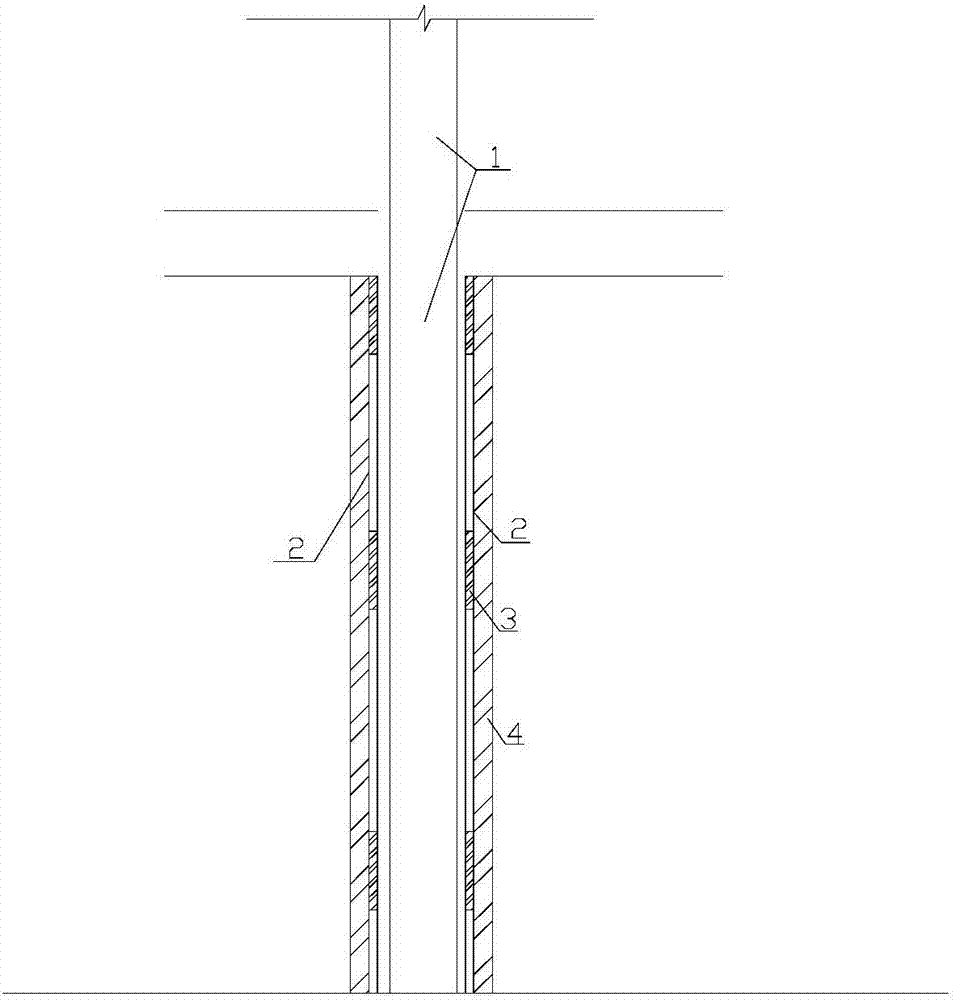

[0014] Describe the steps of construction of the present invention below in conjunction with accompanying drawing:

[0015] (1) Paste the self-adhesive moisture-retaining material 2 on the outside of the vertical concrete member 1 after the formwork is removed.

[0016] (2) Spray water on the moisturizing material 4, and then repeat the water spraying according to the degree of dryness of the moisturizing material 4, and the moisturizing time reaches the number of days of concrete component curing required by the specification.

[0017] (3) After the number of curing days for the concrete components required by the specification is reached, the self-adhesive moisture-retaining material 2 is removed from the vertical concrete components and recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com