Multi-section universal assembly-type reinforcing device for steel structure and its application method

A reinforcement device and multi-section technology, which is applied in building construction, construction, building maintenance, etc., can solve the problems that some rods cannot meet the bearing capacity requirements and the actual construction is inconvenient, so as to achieve good reinforcement effect, simplify the construction plan, reduce the The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further illustrated below by specific examples.

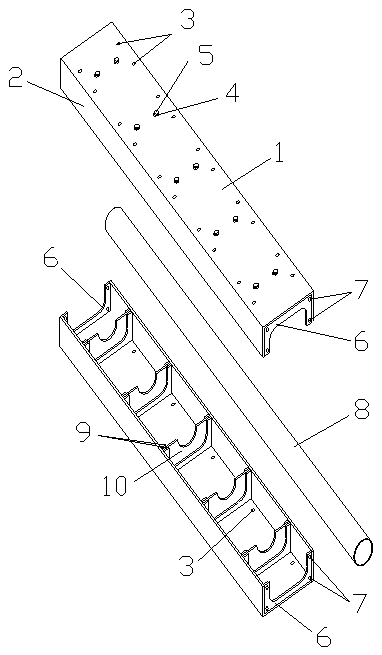

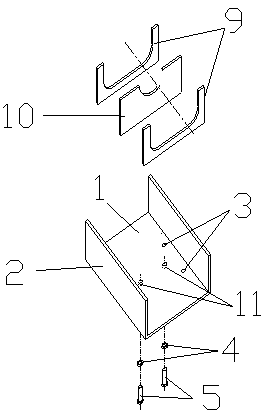

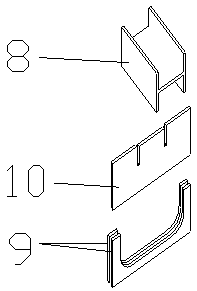

[0026] Such as figure 1 As shown, a multi-section general-purpose assembled reinforcement device for a steel structure includes a pair of symmetrical fixtures, and the fixture consists of a top plate 1, a side plate 2, an end plate 6, a clamping plate 9, a reinforcing plate 10, and a nut 4 and bolts 5, the side plate 2 is vertically welded on both sides of the top plate 1, the end plate 6 is vertically welded on the end of the top plate 1 and is welded vertically with the side plate 2 to form a channel member, and the inner side of the channel member is welded in a number of equal distances along the longitudinal direction. For adjacent clamping plates 9, a clamping groove is formed between pairs of adjacent clamping plates, and the reinforcing plate 10 is inserted into the clamping groove;

[0027] Such as figure 1 As shown, a number of bolt holes 3 are symmetrically opened on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com