Underfloor heating construction method

A construction method and floor heating technology, applied in heating methods, hot water central heating systems, household heating, etc., can solve the problems of waterproof, poor energy saving effect, too simple construction method, not standardized enough, etc., and achieve good waterproof effect and practicality Good performance, better waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

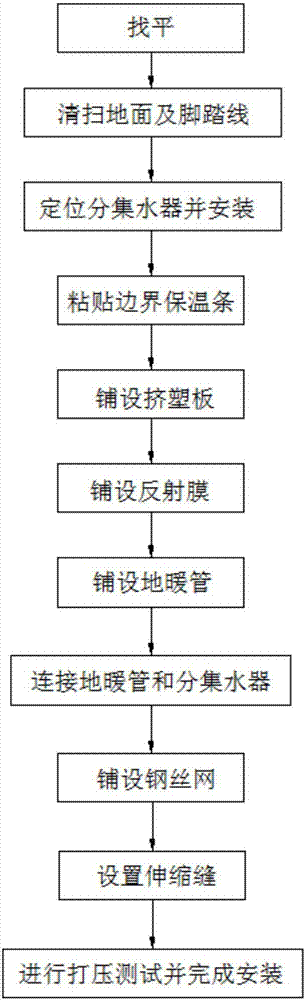

[0027] Such as figure 1 Shown, a kind of floor heating construction method comprises the following steps:

[0028] (1), leveling;

[0029] (2) Clean the ground and the position of the skirting line. Use brooms and cement shovels to remove excess mud and stone dust on the skirting line and the ground to keep the ground clean and flat. After leveling and before installing the positioning sub-catchment, increase the cleaning of the ground and kicking The step of foot line position makes the floor heating construction more standardized;

[0030] (3) Locate and install the sub-catchment, first locate the position of the sub-catchment, then install the bottom plate, and finally install the sub-catchment, clearly explain the construction steps, effectively prevent the installation sequence during the construction process Problems such as inversion and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com