Method and system of testing verticality of two surfaces of object

A technology of verticality and surface measurement, applied in measurement devices, instruments, optical devices, etc., can solve problems such as difficulty in result processing and measurement, achieve the effect of simple and convenient test method, improve measurement efficiency, and omit the result processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

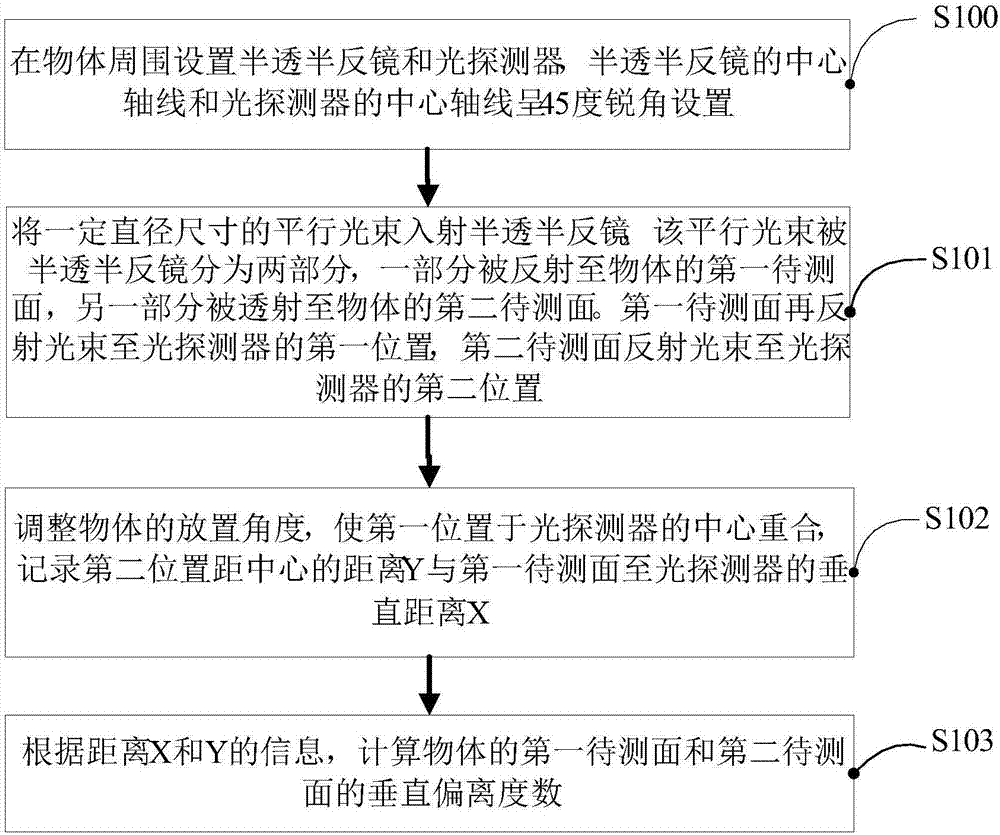

[0025] figure 1 It is a flow chart of the testing method of the present invention. This test method includes:

[0026] In step S100, a half mirror and a photodetector are arranged around the object, and the central axis of the half mirror and the central axis of the photodetector form an acute angle of 45 degrees.

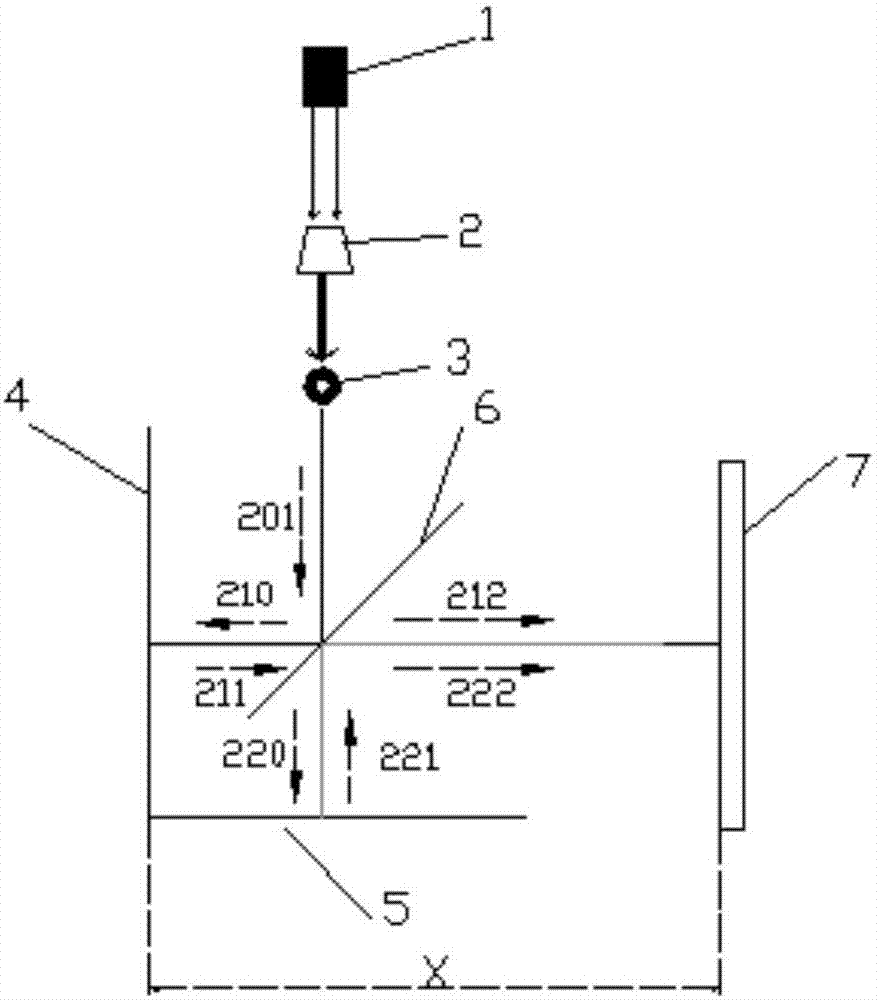

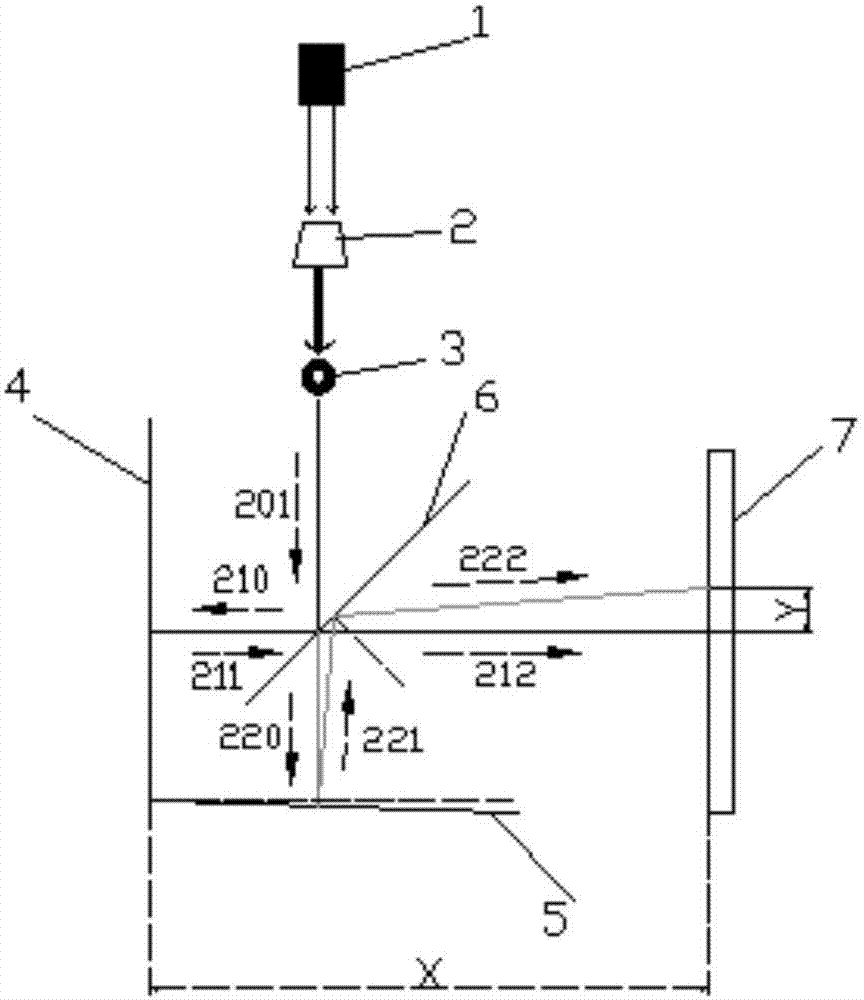

[0027] In step S101, a parallel light beam of a certain diameter is incident on the half-mirror, and the parallel beam is divided into two parts after being incident on the half-mirror, one part is reflected to the first surface to be measured of the object, and the first surface to be measured is Then part of the light beam is reflected to the first position of the light detector; another part is transmitted to the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com