Adjustable chopped infrared carbon-sulfur analyzer and analytic method thereof

An infrared carbon and sulfur analysis, infrared technology, applied in the direction of material analysis, analysis materials, instruments, etc. through optical means, can solve the problems of limited precision, influence of detection signal, low conversion rate of processor, etc., to improve the accuracy of analog-to-digital conversion and rate, improve the level of signal processing, and reduce the effect of background interference signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the drawings.

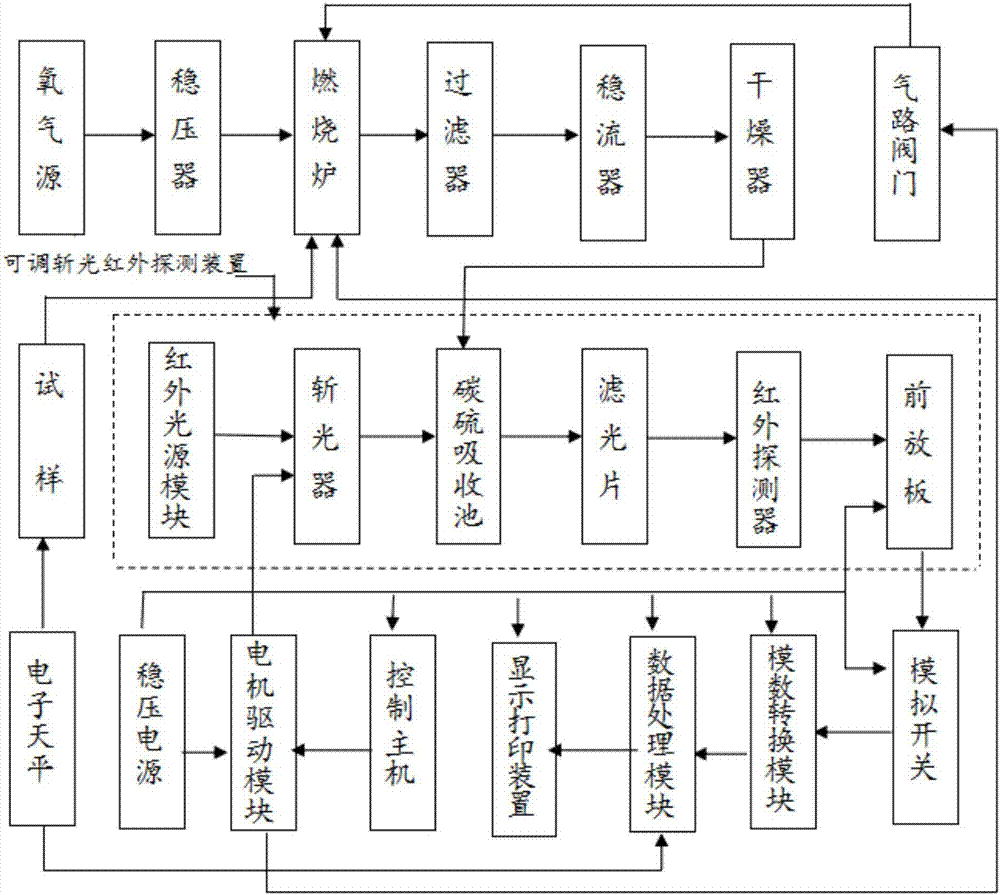

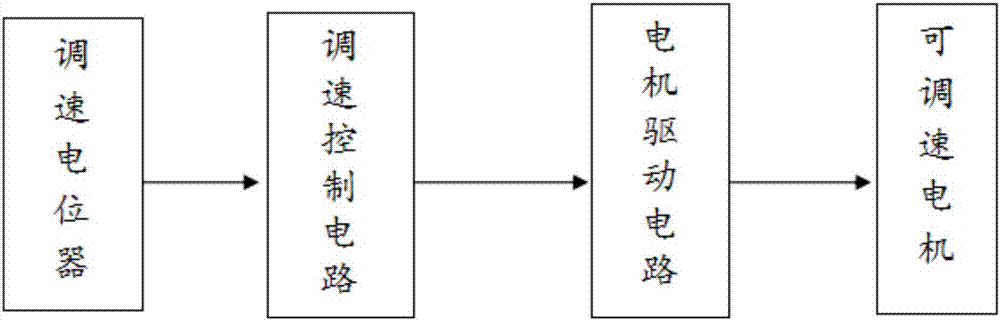

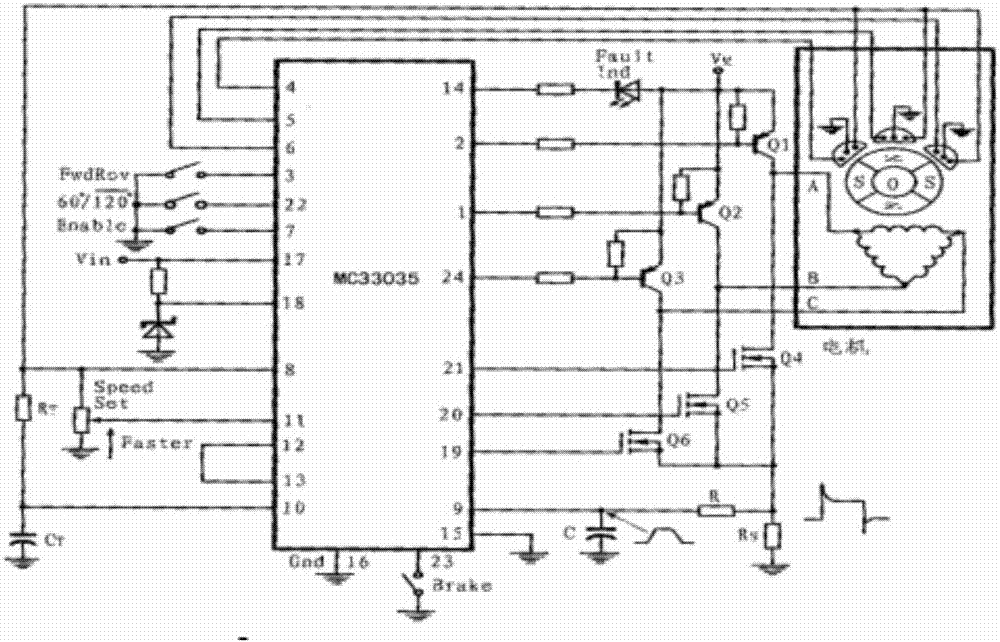

[0030] Such as Figure 1 to Figure 5 Shown is an adjustable chopping infrared carbon and sulfur analyzer of the present invention, used to analyze the content of carbon and sulfur in a sample, including an electronic balance, an oxygen source, a combustion furnace, an adjustable chopping infrared detection device and Control the host, the oxygen source is connected to the combustion furnace through the gas path, the gas path is provided with a voltage stabilizer and a gas path valve connected to the control host, and the output end of the combustion furnace is provided with a filter, a flow stabilizer and a dryer, which are adjustable The chopping infrared detection device includes an infrared light source module and a chopper for generating an infrared measurement light source with adjustable chopping frequency, and a carbon and sulfur absorption cell for detecting the carbon and sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com