lens

A lens and lens barrel technology, applied in the field of lens, can solve the problem of low efficiency of lens disassembly and assembly, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0036] An embodiment of the present invention provides a lens, which can be used in electronic devices such as digital cameras, video cameras, mobile phones, and tablets, especially for digital cameras with interchangeable lenses. When in use, install the lens on the body.

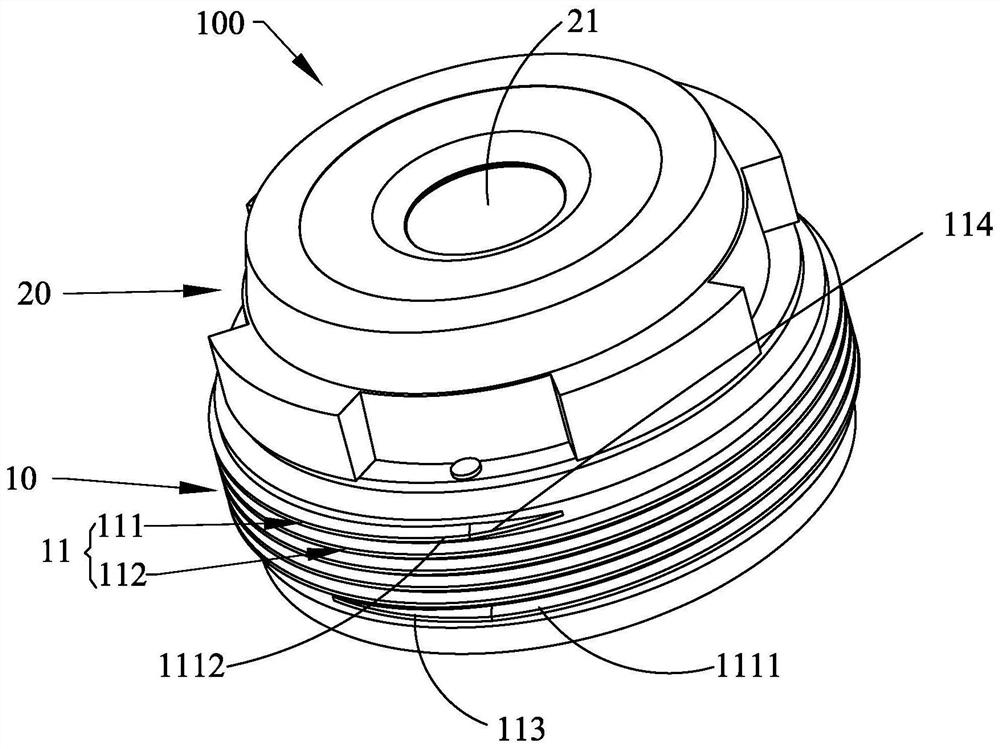

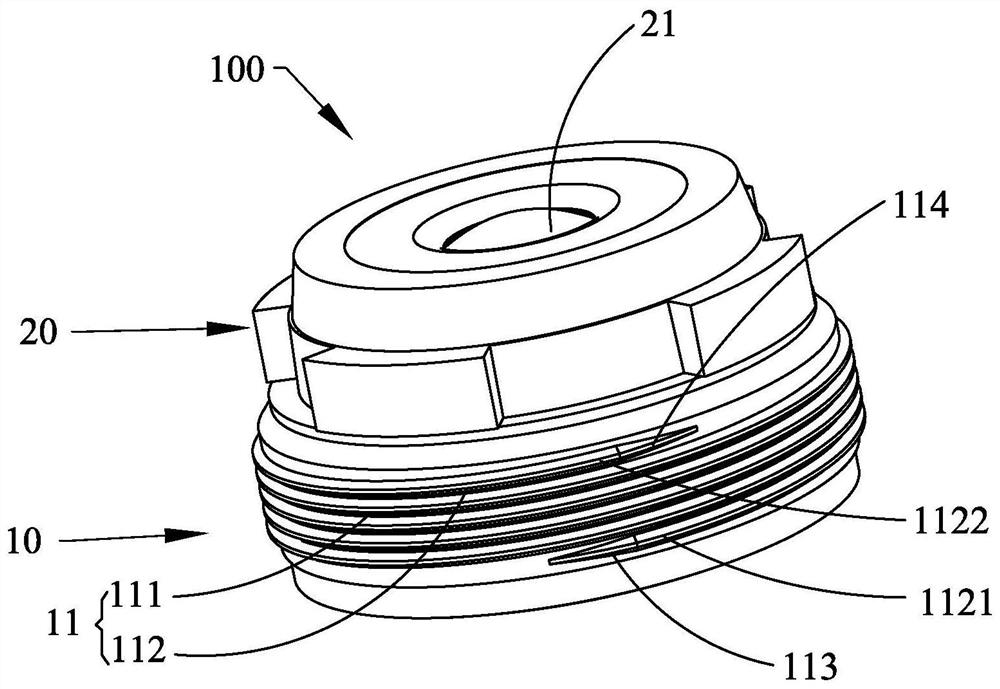

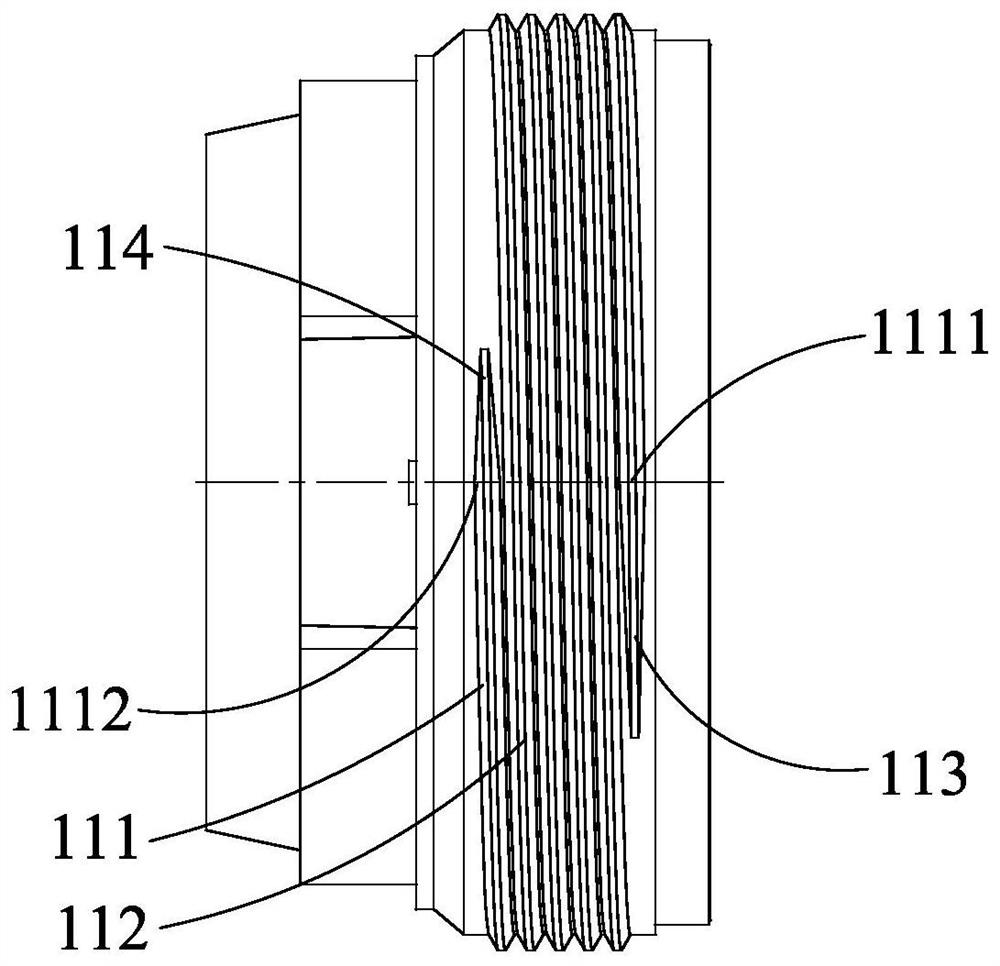

[0037] Such as Figure 1-4 As shown, the lens includes a lens barrel 100, the lens barrel 100 includes a first barrel wall 20 forming a light hole 21 and a second barrel wall 10 bent and extended from the first barrel wall 20, the second barrel wall 10 includes an inner wall and The outer wall opposite the inner wall is provided with a multi-thread thread structure 11, the multi-thread thread structure at least includes a first thread 111 and a second thread 112, and the thread lines of the second thread 112 are arranged on two adjacent turns of the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com