A Production Planning Method Based on Deep Analysis of Quality Data

A quality data and production planning technology, applied in data processing applications, electrical digital data processing, digital data information retrieval, etc., can solve the problems of low feasibility, less knowledge-based and intelligent integrated application technology solutions, frequent scheduling work, etc. problems, to achieve the effect of improving quality and improving the level of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiment of the present invention is described in detail below in conjunction with example, this example is the implementation process based on the premise of the technical solution of the invention, provides detailed implementation and specific implementation process, but the protection scope of the present invention is not limited to the following instance.

[0038] This embodiment adopts a production plan preparation method based on in-depth analysis of quality data on the manufacturing execution system platform to quickly and optimize the preparation of production plans or operation plans during the production process of large parts of a certain model.

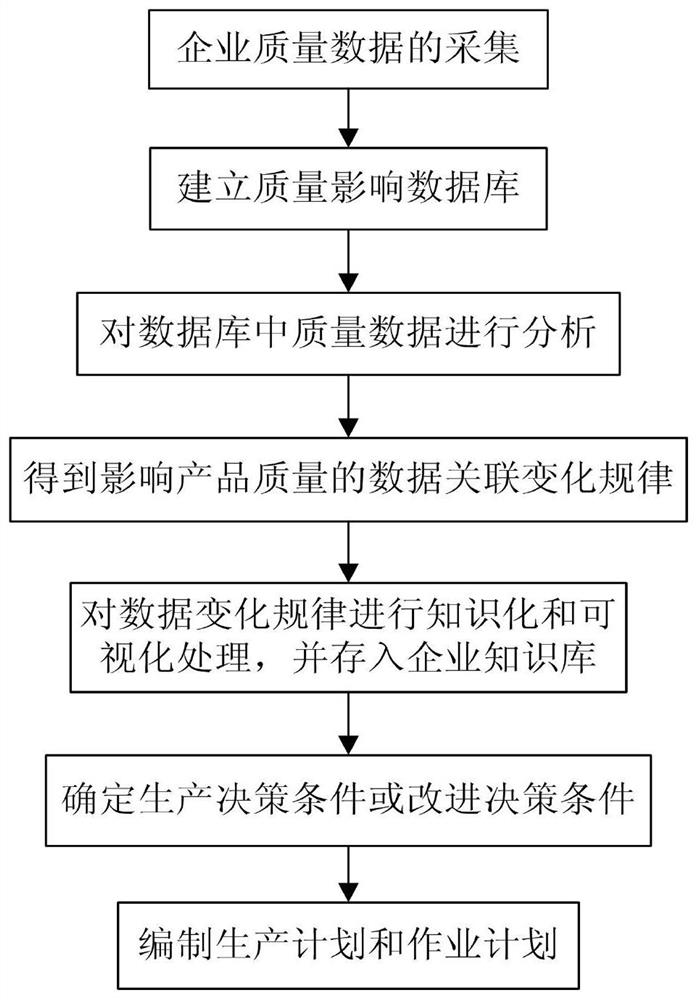

[0039] A production planning method based on in-depth analysis of quality data, such as figure 1 shown, including the following steps:

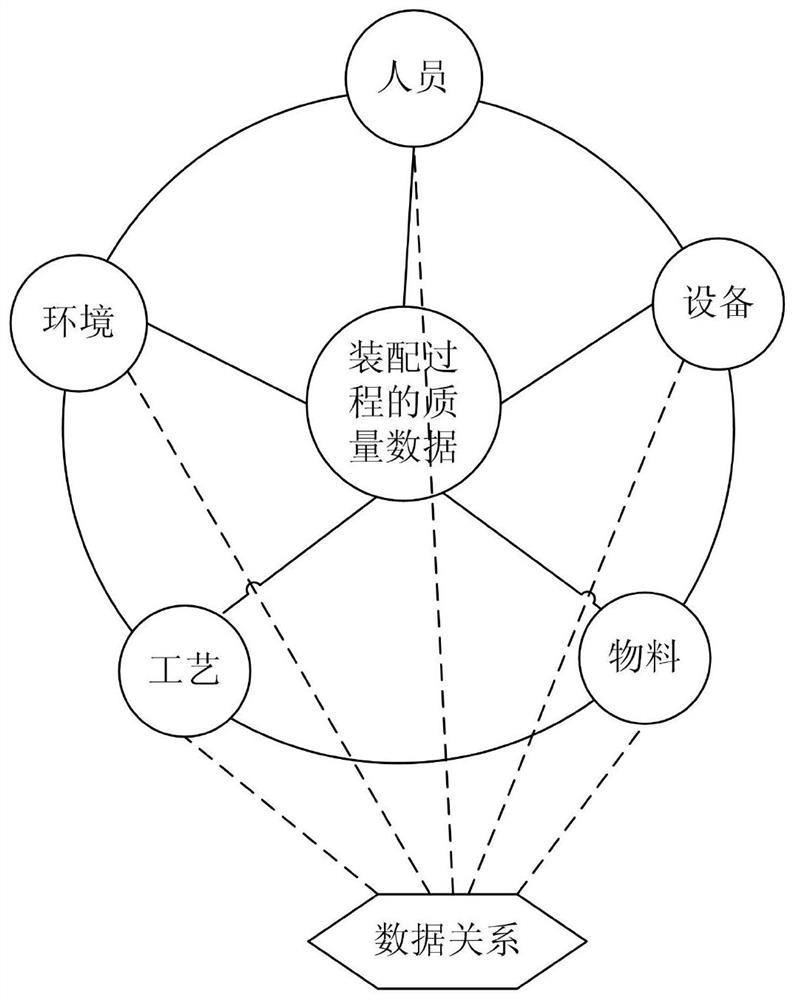

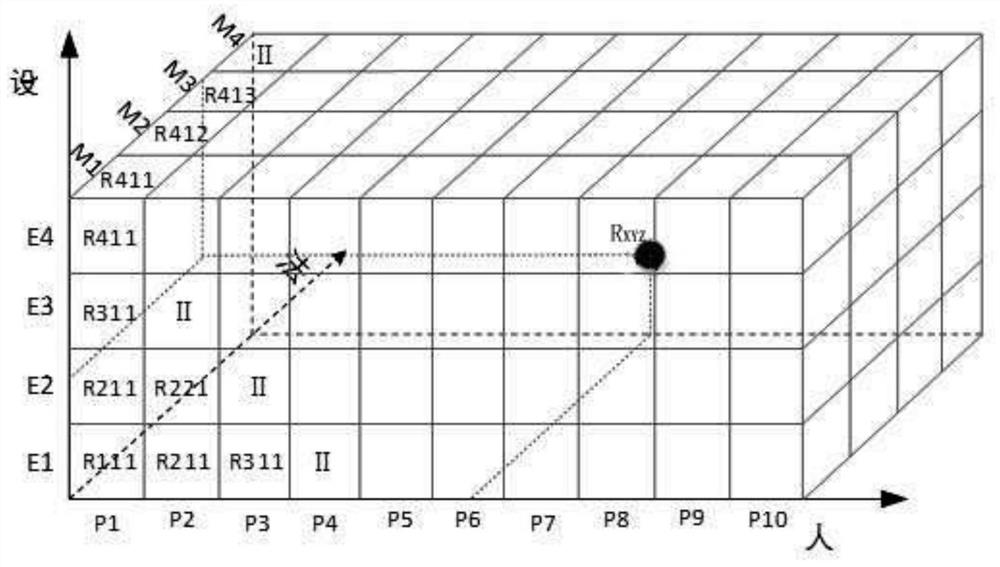

[0040] Step 1: Take the characteristic data of the five aspects of personnel, equipment, materials, processes, and environment as the collection object, and collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com