Working method of high-precision glue-wrapping device for cable processing

A technology of encapsulation device and working method, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., which can solve the problem of cable processing consistency and quality cannot be well guaranteed, and the height adjustment of the pressing mechanism is easy to appear Position deviation, low cable positioning accuracy and other problems, to achieve good cooling effect, ensure consistency and quality, and good lighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

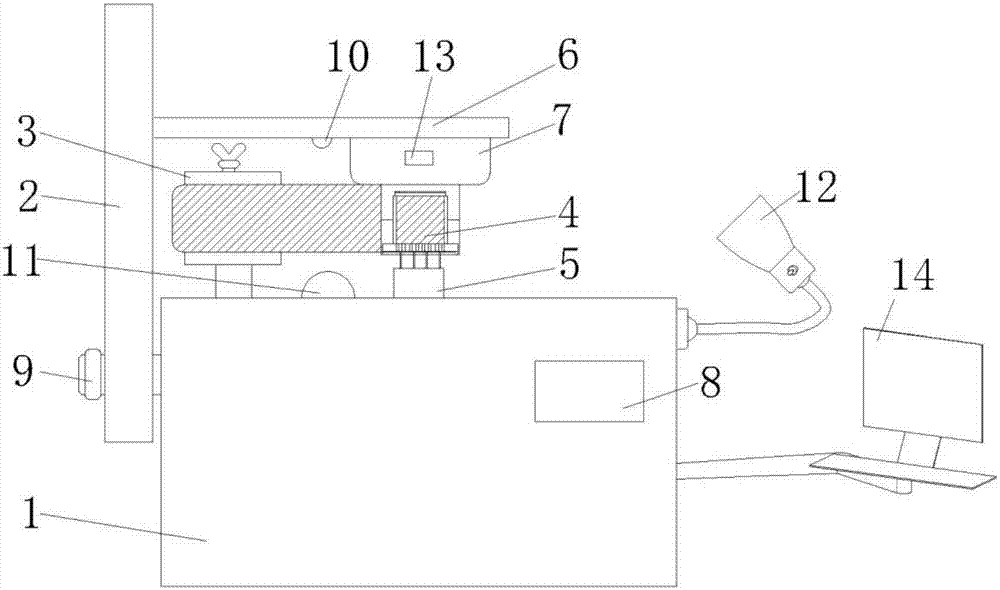

[0035] Such as figure 1 As shown, the working method of a high-precision rubber covering device for cable processing in this embodiment, the specific working steps are as follows:

[0036] (1) The staff first fix the cable on the corresponding jig 4, fix the matching tape fixing mechanism 3 on the frame 1, and turn on the LED light 12 on one side of the frame 1;

[0037] (2) The staff set the working parameters of the rotating mechanism 5 and the pressing mechanism 7 through the control panel 8, and turn on the power supply of the motor 2 through the control panel 8;

[0038] (3) The motor 2 drives the slide bar 6 to drive the compression mechanism 7 to move downward, and through the cooperation of the compression mechanism 7 and the jig 4 to fix the cable, the staff can judge the pressure through the laser head 10 connected to the display 14. The exact height of the tightening mechanism 7 and the cable;

[0039] (4), then the staff turns on the power supply of the rotating me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com