Large-size electric reactor mould assembly platform

A reactor and platform technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve problems such as unsafe, time-consuming and labor-intensive, and achieve the effects of improving safety, adjustable height, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

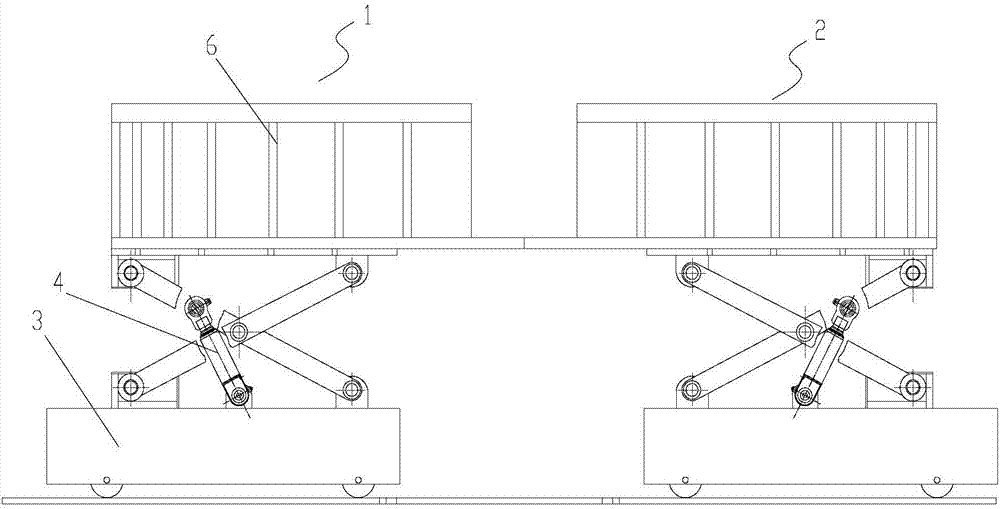

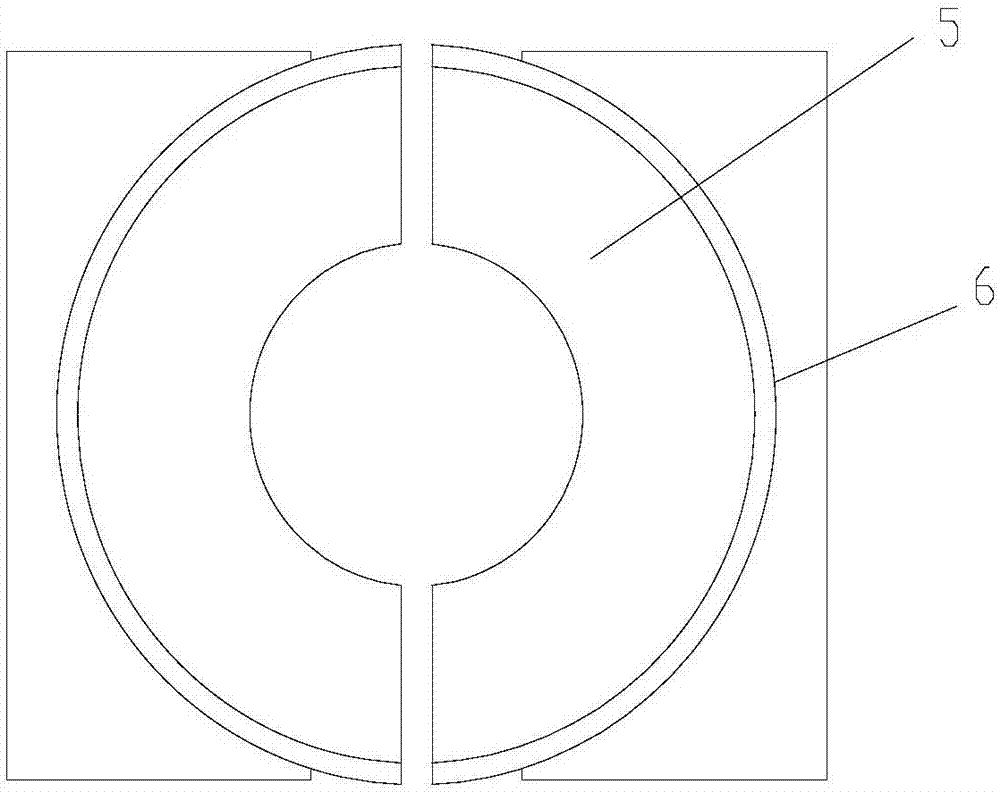

[0010] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1-2 As shown, a large-scale reactor molding platform includes a left platform 1 and a right platform 2 with the same structure, and the left platform and the right platform are arranged symmetrically. Lifting platform 4; the scissor lift platform adopts the existing structure, including scissors and a cylinder driving the scissors, and the movement of the scissors driven by the cylinder can make the upper walking table go up and down. The bottom of the mobile car cooperates with the track, the scissor lift platform is fixed on the mobile car, and the upper part of the scissor lift platform is provided with a walking table 5, and the walking table is semicircular , Guardrail 6 is provided around the walking table. A ladder is provided on one side of the walking platform. Go up the ladder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com