Cooling and heating system of power battery of electric automobile

A power battery and electric vehicle technology, applied in electric vehicles, secondary batteries, electric traction, etc., can solve the problems of complex structure of temperature control system, high energy consumption of battery cooling and heating, battery pack occupation, etc., to extend battery life , reduce electric energy, improve the effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

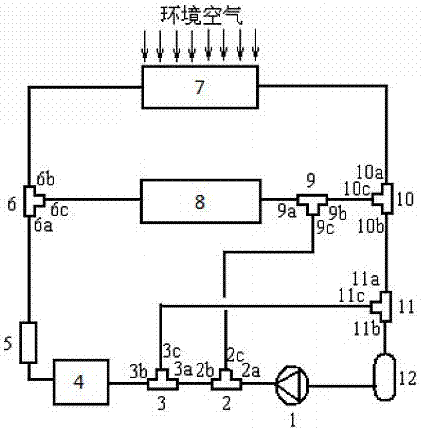

[0070] see image 3 . A cooling and heating system for a power battery of an electric vehicle adopts the structure of sharing a set of vapor compression refrigeration system with the air-conditioning and refrigeration system of the electric vehicle. The working medium used is a refrigerant in a vapor-liquid two-phase state within the operating temperature range. For ease of distinction, the refrigerant of the vapor compression refrigeration system is referred to as the first refrigerant, and the working fluid used to cool the battery is referred to as the second refrigerant.

[0071] The cooling and heating system includes a working fluid pump 1, the first three-way valve 2, the second three-way valve 3, the battery heat exchanger 4, the auxiliary electric heater 5, the third three-way valve 6, and the second heat exchanger 7. The first heat exchanger 8, the fourth three-way valve 9, the third three-way valve 10, the sixth three-way valve 11, the liquid reservoir 12, the com...

Embodiment 2

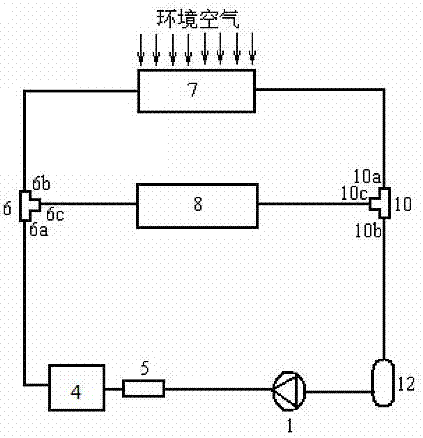

[0082] see Figure 4 . A cooling and heating system for a power battery of an electric vehicle adopts the structure of an independent vapor compression refrigeration system; it includes a working fluid pump 1, a first three-way valve 2, a second three-way valve 3, a battery heat exchanger 4, and an auxiliary Electric heater 5, III three-way valve 6, second heat exchanger 7, first heat exchanger 8, IV three-way valve 9, V three-way valve 10, VI three-way valve 11, liquid reservoir 12 and compressor 13, four-way valve 14, third heat exchanger 15, throttling mechanism 16; and share the first heat exchanger 8. The working medium used is a refrigerant in a vapor-liquid two-phase state within the operating temperature range. For ease of distinction, the refrigerant of the vapor compression refrigeration system is referred to as the first refrigerant, and the working fluid used to cool the battery is referred to as the second refrigerant.

[0083] In practice, the same or similar ...

Embodiment 3

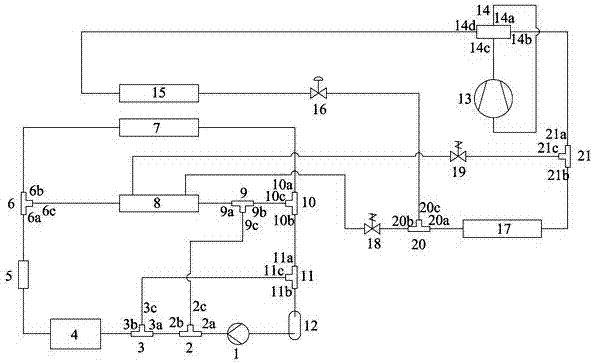

[0094] see Figure 5 . A cooling and heating system for a power battery of an electric vehicle adopts the structure of sharing a set of vapor compression refrigeration system with the air-conditioning and refrigeration system of the electric vehicle. The working fluid used is a working fluid that is always in a liquid state within the operating temperature range. To make a distinction, the refrigerant of the vapor compression refrigeration system used in the electric vehicle air conditioner is called the refrigerant; the working medium of the cooling and heating system of the power battery is called the working medium.

[0095] The cooling and heating system includes a working fluid pump 1, a battery heat exchanger 4, an auxiliary electric heater 5, a third three-way valve 6, a second heat exchanger 7, a first heat exchanger 8, and a fifth three-way valve 10. Liquid reservoir 12 and compressor 13, four-way valve 14, third heat exchanger 15, throttling mechanism 16, fourth he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com