Steel containment vessel end sealing plate turnover device and operation method

A steel containment and flipping device technology, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of high shift fees for cranes, affecting the overall structure of equipment, and many flipping times, so as to reduce flipping operations Effort and cost, avoidance of unhooking and hooking process, effect of simple reversal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

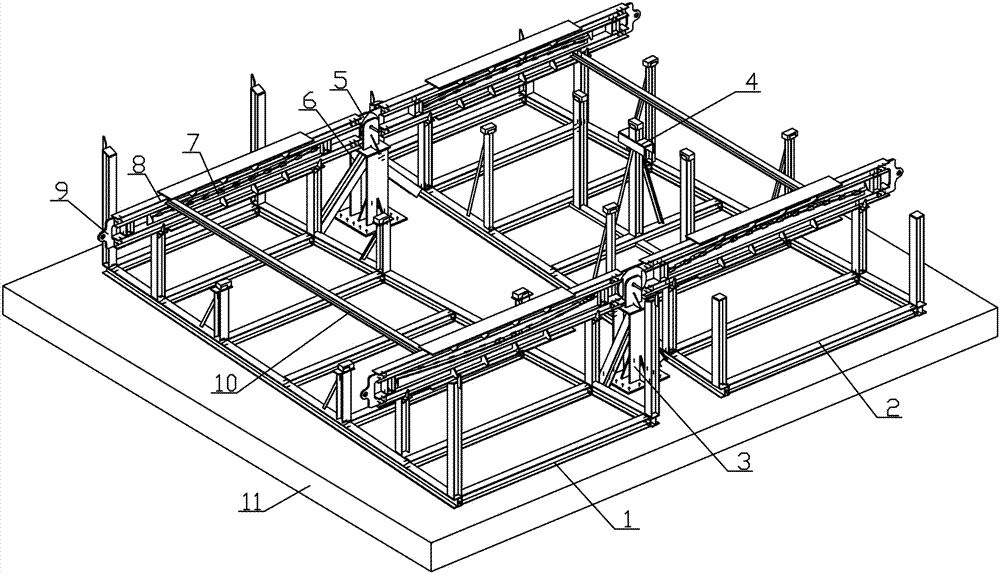

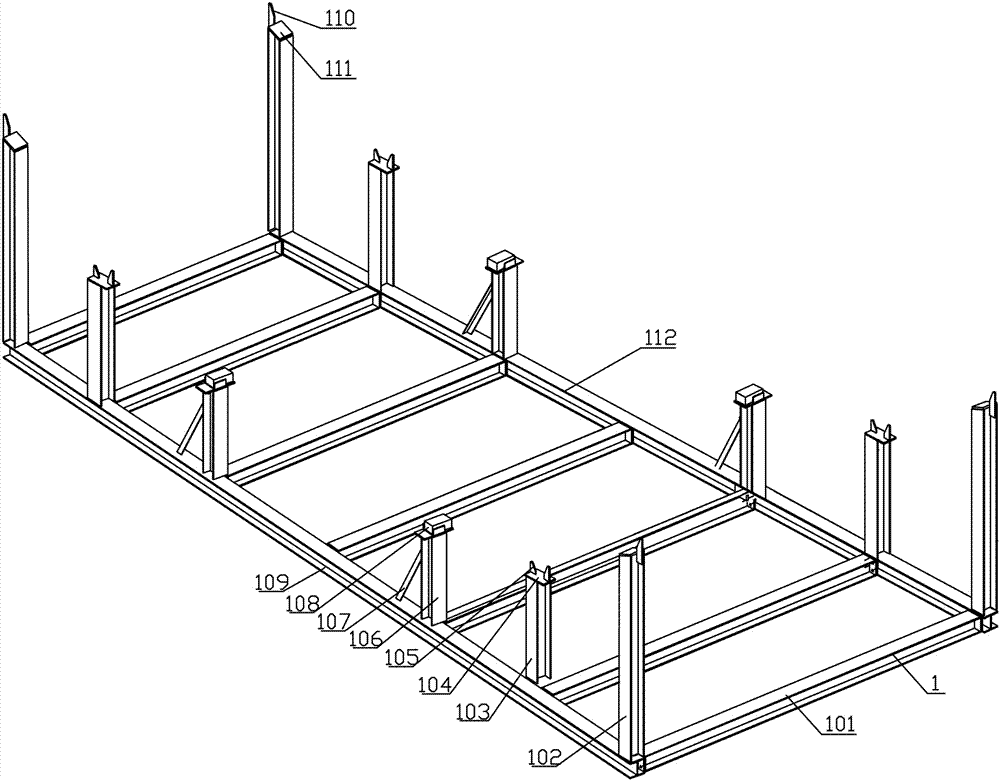

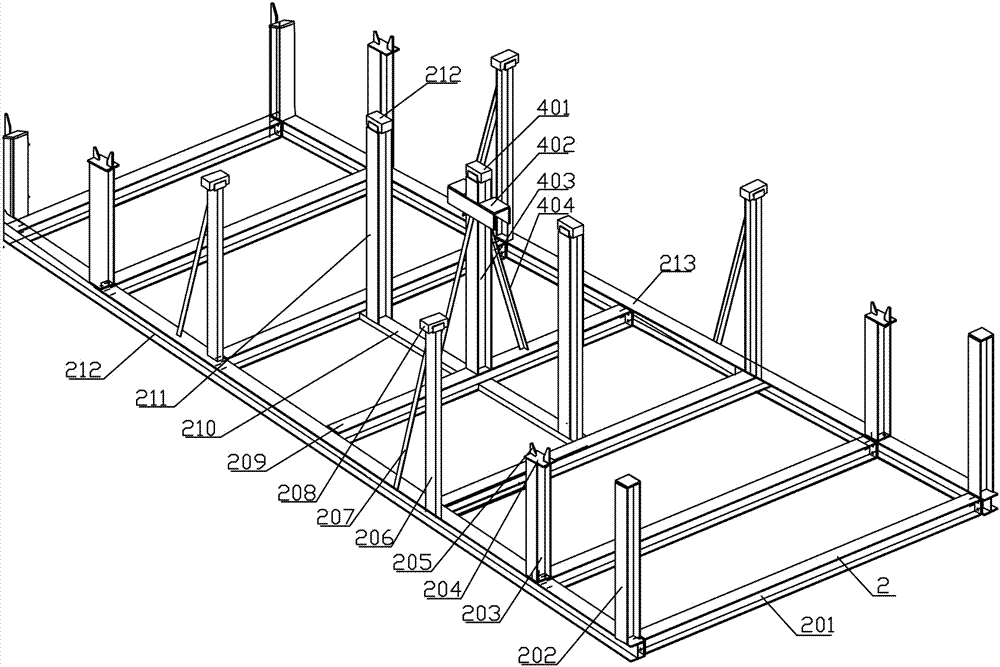

[0047] see Figure 1-7 , a steel containment head plate overturning device, which includes a concave storage bracket 1 and a convex storage bracket 2, the concave storage bracket 1 and the convex storage bracket 2 are arranged side by side, and a first The flipping bracket 3 and the second flipping bracket 6 are hinged on the first flipping bracket 3 and the second flipping bracket 6 respectively with flipping fixtures; by fixing the flipping bracket and the ground through expansion bolts, the flipping fixture is attached to the head board and Provide sufficient clamping force; the two are connected by a fixed shaft, and one end of the flip clamp is connected to a crane, which is powered by the crane to flip around the fixed shaft. The convex storage bracket and the concave storage bracket are arranged on both sides of the flip bracket, so that the flipped The head plate is directly in place to facilitate the development of the next process.

[0048] Further, the flipping fix...

Embodiment 2

[0065] Using any one of the operation methods of the steel containment head plate turning device, it is characterized by comprising the following steps:

[0066] Step1: Hoist the steel containment head plate to the concave storage bracket 1, and make the concave surface structure formed by the first pole 102, the second pole 103 and the third pole 106 of the concave storage bracket 1 match the same The convex surface of the steel containment head plate is matched to support it;

[0067] Step2: Set the convex clip body 8 and the concave clip body 7 on the upper and lower ends of the steel containment head plate, and use the first connecting plate 9 and the second connecting plate 5 to fix and connect the two ends respectively, so that the steel The containment head plate is clamped inside the flipping fixture, and then the second connecting plate 5 is hinged on the top of the flipping bracket through a pin shaft; there are two sets of flipping fixtures;

[0068] Step3: When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com