High-precision light-curing resin molding 3D printer

A light-curing resin and 3D printer technology, applied to 3D object support structures, manufacturing tools, accessories for processing main materials, etc., can solve the problems of fixing the printing platform, reducing light transmittance, thermal deformation of the bottom plate, etc., to avoid printing errors , improve transmittance, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

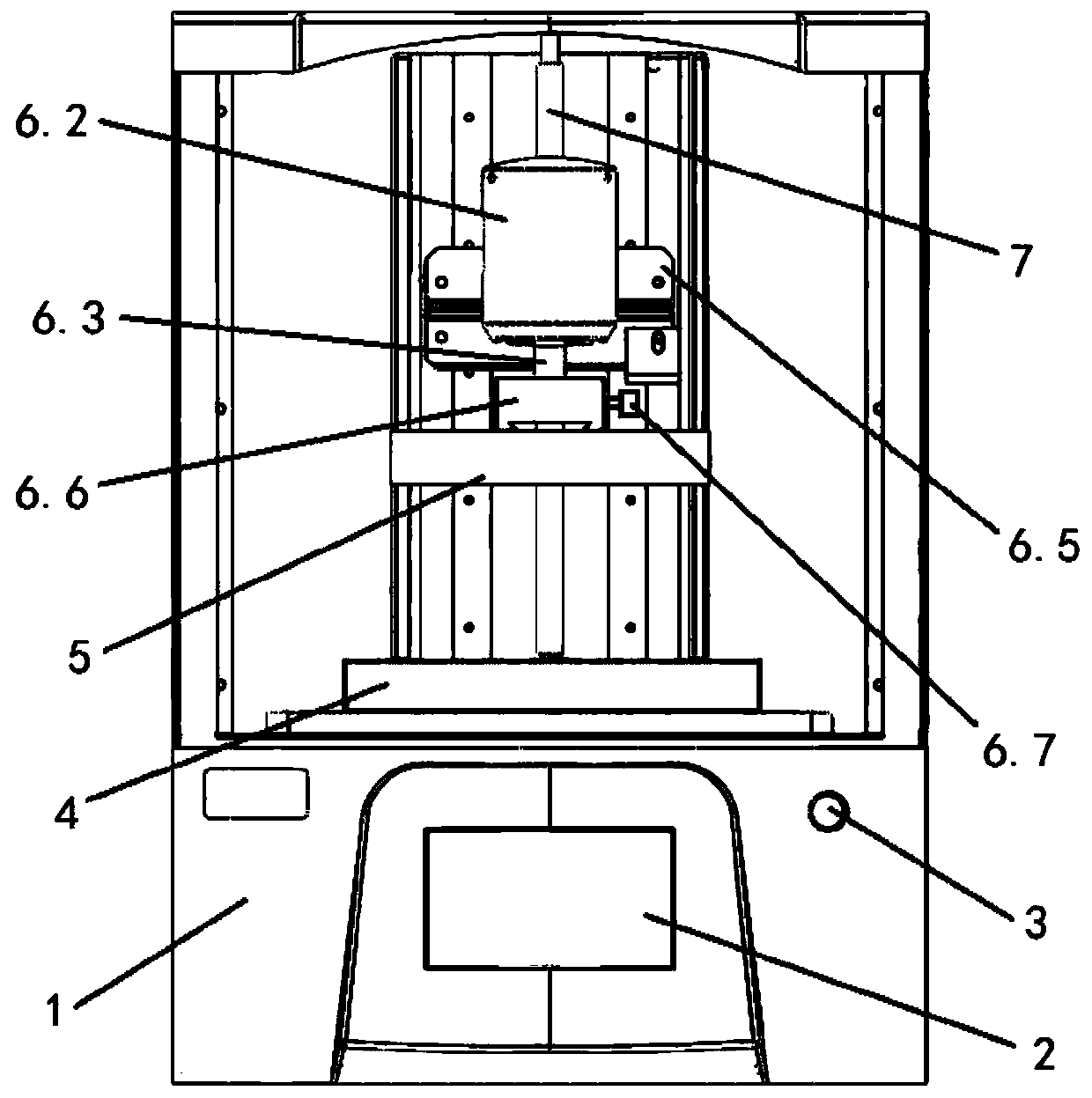

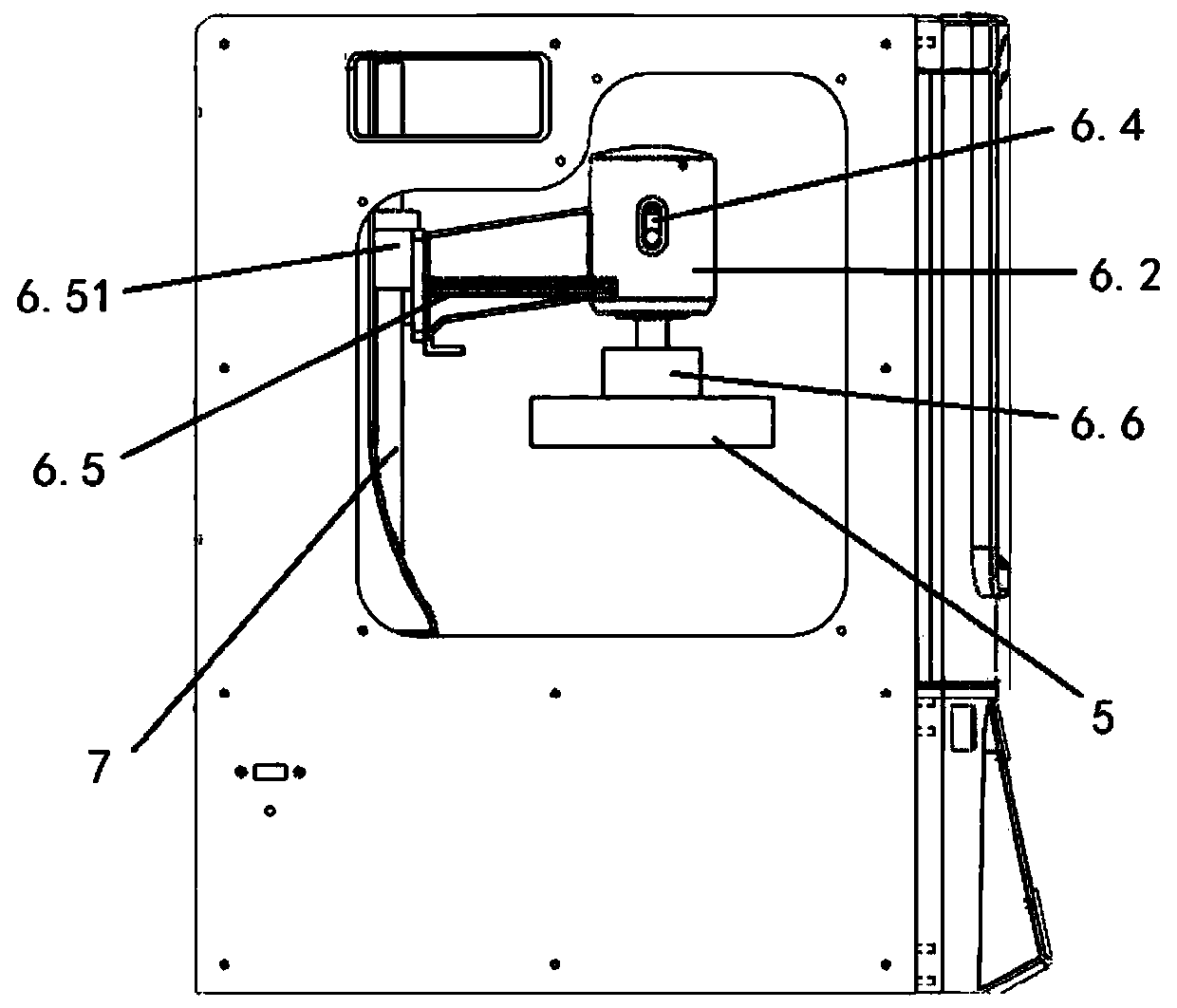

[0021] Attached below Figure 1-4 The present invention is described further:

[0022] A high-precision light-curing resin molding 3D printer, including a housing 1, a control display 2 and a switch 3 are provided at the lower part of the housing 1, an LED light source is provided at the inner bottom of the housing 1, a liquid storage tank 4 is provided above the LED light source, and a liquid storage tank 4 is provided above A printing platform 5 is provided, and the printing platform 5 is slidingly connected to the lifting column 7 through a platform fixing device, the platform fixing device is connected to the lifting drive mechanism, and the control display screen is connected to control the LED light source and the lifting drive mechanism through the control system;

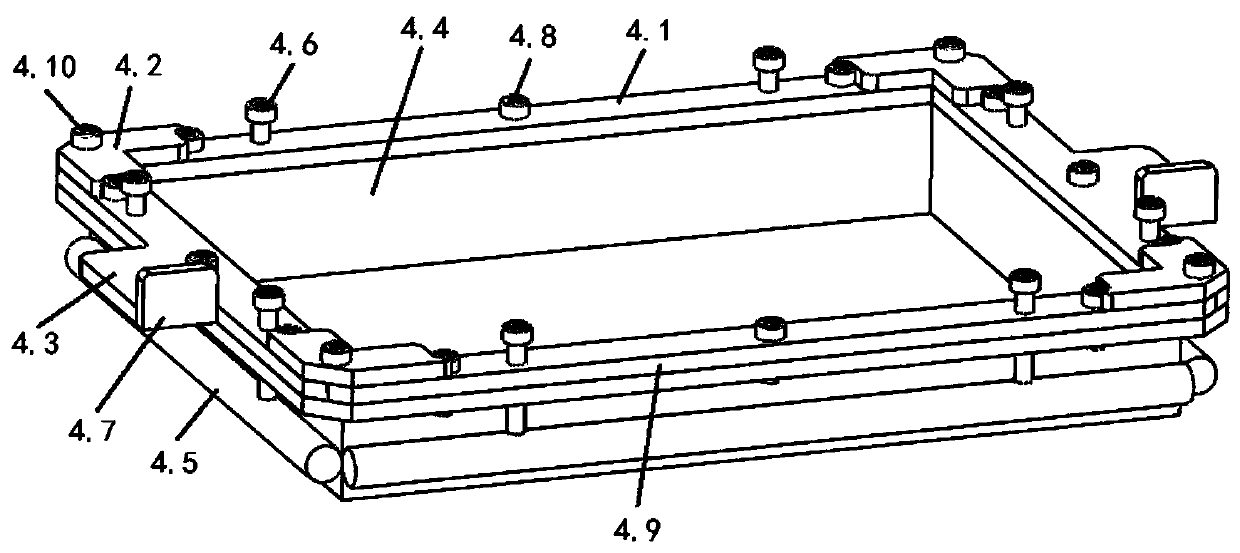

[0023] The liquid storage tank 4 includes a side wall 4.4, and the top of the side wall 4.4 is connected with an everted outer edge 4.9, and the upper surface of the outer edge 4.9 is attached to a release f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com