Automobile provided with strengthened heat dissipation wheels

A heat-dissipating, wheel technology, applied in tire measurement, vehicle parts, tire parts, etc., can solve the problem of poor heat dissipation effect of wheels, and achieve the effect of good cooling effect and good heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

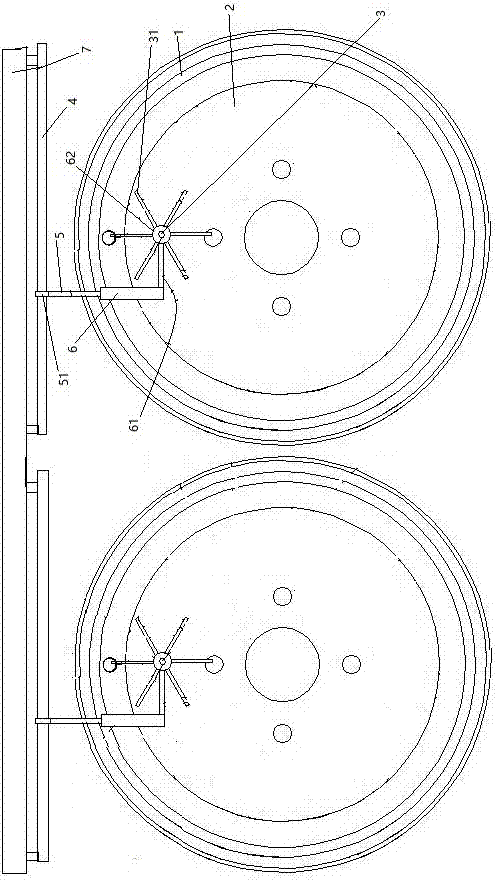

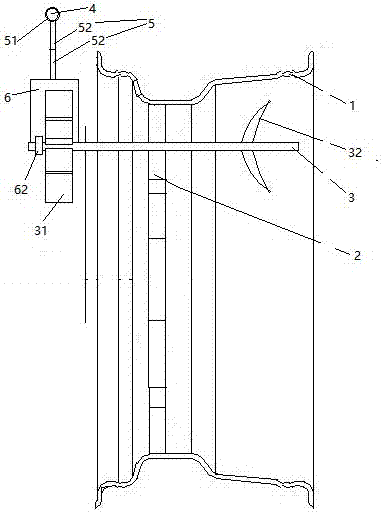

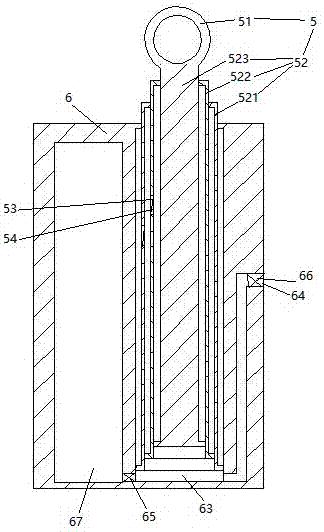

[0017] see figure 1 , a wheel-enhanced heat-dissipating vehicle includes a vehicle frame 7 and at least two rows of wheels supporting the vehicle frame. A slide bar 4 extending in the front-rear direction is connected to the vehicle frame 7 . The wheel comprises a rim 1, a spoke 2 and a telescopic rod 5.

[0018] The spoke 2 is rotatably connected with a drive shaft 3 . The transmission shaft 3 is connected with a number of windward blades 31 distributed along the circumference of the transmission shaft and driven by the wind generated by the running of the vehicle to drive the transmission shaft to rotate. The windward vanes 31 are flat plate structures. The plane where the windward vanes 31 are located is parallel to the transmission shaft 3 .

[0019] The slide bar 4 is located above the drive shaft 3 . Slide bar 4 is vertical with transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com