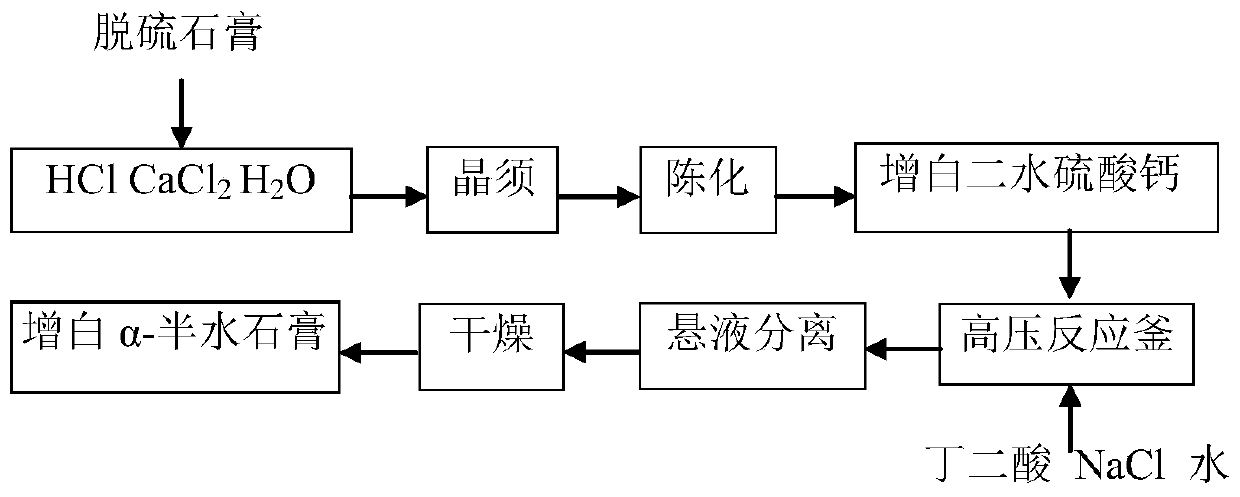

A method for preparing high whiteness short columnar α-hemihydrate gypsum from desulfurized gypsum

A technology of hemihydrate gypsum and desulfurized gypsum, applied in chemical instruments and methods, calcium/strontium/barium sulfate, inorganic chemistry, etc., can solve problems such as secondary pollution, improve whiteness value, solve a large number of accumulations, improve The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the specific operations are as follows

[0035] (1) Crystal transformation:

[0036]a. Mix concentrated hydrochloric acid, water, calcium chloride, and desulfurized gypsum according to water: concentrated hydrochloric acid (12mol / L): CaCl 2 : Desulfurized gypsum=100mL:8mL:1g:10g The prepared reaction slurry is placed in a three-necked flask, and heated to 100°C for 285min;

[0037] b. Let the slurry obtained in a. stand at a constant temperature of 25°C for 8 hours;

[0038] (2) Filter the slurry obtained in step (1), and wash with deionized water until neutral;

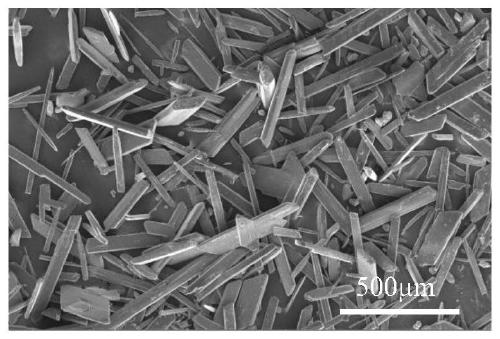

[0039] (3) Drying: Dry the product obtained in step (2) at 45°C for 10 hours to obtain the intermediate product, as shown in the attached figure 2 ;

[0040] (4) Water, intermediate product, NaCl, and succinic acid are prepared according to the mass ratio: water: intermediate product: NaCl: succinic acid=100:14:3:0.07 to prepare a reaction slurry, and adjust the acidity and alkalinity of the...

Embodiment 2

[0045] Embodiment 2: specific operation is as follows

[0046] (1) Crystal transformation:

[0047] a. Mix concentrated hydrochloric acid, water, calcium chloride, and desulfurized gypsum according to water: concentrated hydrochloric acid (12mol / L): CaCl 2 : The ratio of desulfurized gypsum=100mL:8mL:1g:10g is prepared and the reaction slurry is placed in a three-necked flask, and heated to 100°C for 285min;

[0048] b. Let the slurry obtained in a. stand at a constant temperature of 25°C for 8 hours;

[0049] (2) Filter the slurry obtained in step (1), and wash with deionized water until neutral;

[0050] (3) drying: drying the product obtained in step (2) at 45°C for 10 hours to obtain the intermediate product;

[0051] (4) Water, intermediate product, NaCl, and succinic acid are prepared according to the mass ratio: water: intermediate product: NaCl: succinic acid=100:16:3:0.07 to prepare a reaction slurry, and adjust the acidity and alkalinity of the slurry to pH =9; ...

Embodiment 3

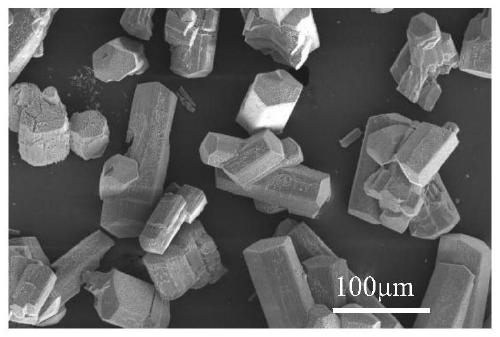

[0054] Referring to the method in GB / T5950-2008, the R457 whiteness value (Wr) of the product measured is 88.22%. Too much middle affects the heat transfer and mass transfer of this process, and a small amount of colored impurities affects further separation. A slight drop, but still close to 90%. Embodiment 3: specific operations are as follows

[0055] (1) Crystal transformation:

[0056] a. Mix concentrated hydrochloric acid, water, calcium chloride, and desulfurized gypsum according to water: concentrated hydrochloric acid (12mol / L): CaCl 2 : The ratio of desulfurized gypsum=100mL:8mL:1g:10g is prepared and the reaction slurry is placed in a three-necked flask, and heated to 100°C for 285min;

[0057] b. Let the slurry obtained in a. stand at a constant temperature of 25°C for 8 hours;

[0058] (2) Filter the slurry obtained in step (1), and wash with deionized water until neutral;

[0059] (3) drying: drying the product obtained in step (2) at 45°C for 10 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com