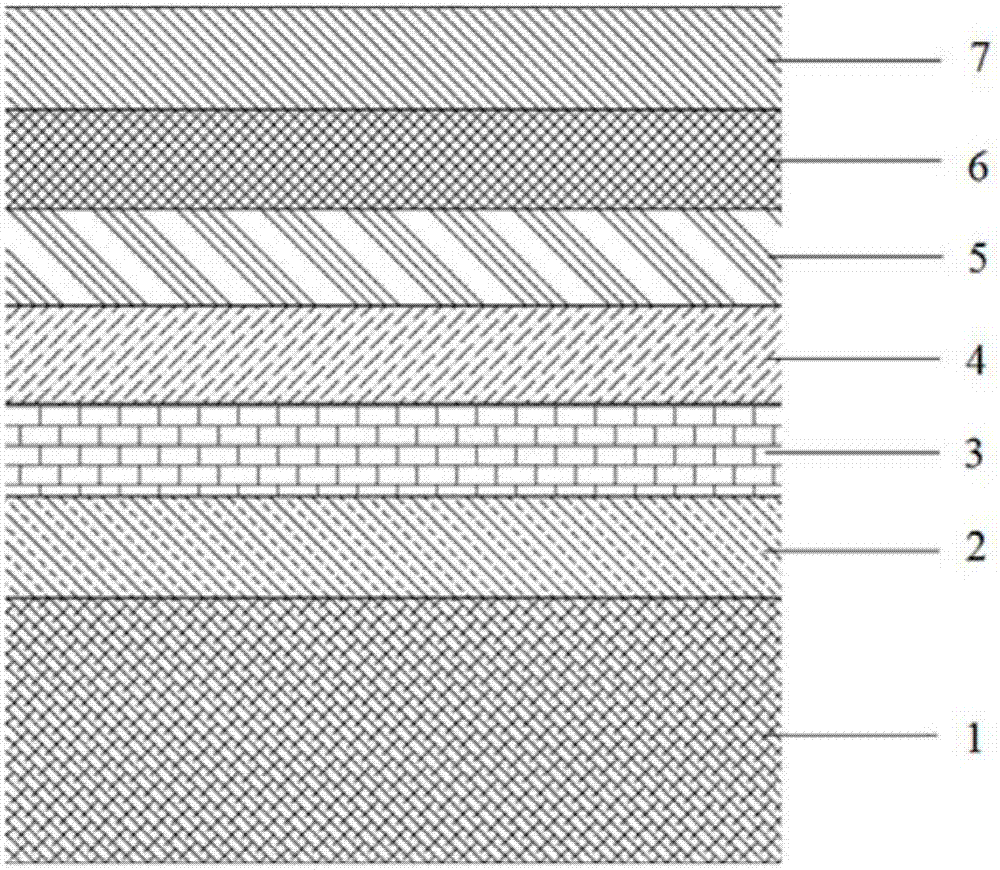

Diamond-like carbon (DLC) thin film and preparation method thereof

A diamond film and type technology, which is applied in metal material coating process, ion implantation plating, gaseous chemical plating, etc., can solve difficult composition transition and structural transition, difficult bonding force, and can not improve the DLC layer. Problems such as adhesion to the substrate surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In one embodiment, a kind of preparation method of diamond-like carbon film, comprises the steps:

[0038] Preparing a metal carbide transition layer on the substrate;

[0039] By performing the PECVD process and the PVD process simultaneously, a metal W-doped DLC transition layer is formed on the metal carbide transition layer, wherein the control pulse bias voltage is gradually increased, and the WC target current is gradually decreased, so that the metal W-doped DLC The transition layer gradually transitions from metal W as the main body to DLC as the main body from the inside to the outside;

[0040] A DLC layer is formed on the metal W-doped DLC transition layer by PECVD.

[0041] In a specific embodiment, the preparation method of the diamond-like film may include the following steps:

[0042] Step 1. Multi-arc ion cleaning: put the workpiece in the vacuum chamber, start vacuuming, turn on the heater at the same time, set the temperature in the furnace, and when t...

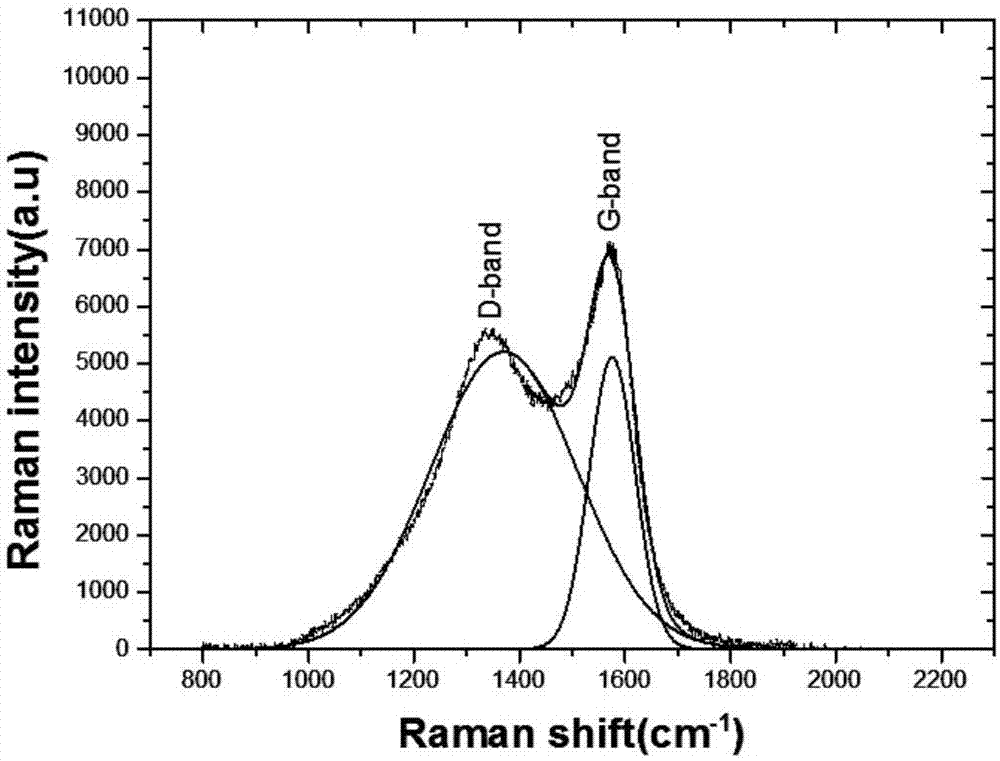

example 1

[0051] Step 1. Clean the surface of the workpiece: place the stainless steel workpiece in the vacuum chamber of the vacuum coating machine, turn on the vacuum pump and heater, set the temperature in the furnace to 200°C, and wait until the vacuum degree of the vacuum chamber reaches 1.0×10 -2 Pa, turn off the heater; pass in argon gas with a flow rate of 150sccm, control the pressure in the vacuum chamber to be about 0.35Pa; turn on the pulse bias power supply, set the bias value to 300V, and the duty cycle to 50%; then turn on one by one For the arc source, adjust the arc current to 80A, and turn off the arc source and bias power supply in sequence after cleaning for 120s.

[0052] Step 2. Prepare a pure metal transition layer: Introduce argon gas with a flow rate of 200 sccm into the vacuum chamber, control the pressure in the vacuum chamber to be about 0.35 Pa; turn on the pulse bias power supply, set the bias value to 100V, and the duty cycle to be 50%; turn on the interme...

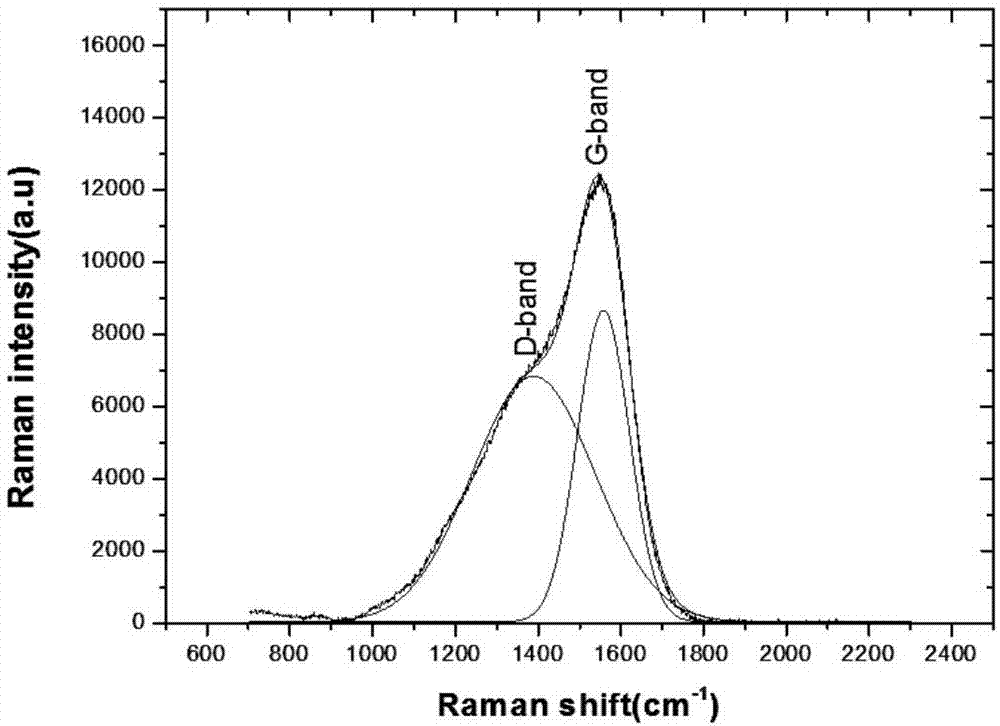

example 2

[0060] Step 1. Clean the surface of the workpiece: place the stainless steel workpiece in the vacuum chamber of the vacuum coating machine, turn on the vacuum pump and heater, set the temperature in the furnace to 150°C, and wait until the vacuum degree of the vacuum chamber reaches 1.0×10 -2 Pa, turn off the heater; pass in argon gas with a flow rate of 100sccm, and control the pressure in the vacuum chamber to be about 0.3Pa; turn on the pulse bias power supply, set the bias value to 400V, and the duty cycle to 40%; then turn on one by one For the arc source, adjust the arc current to 100A, and turn off the arc source and bias power supply in sequence after cleaning for 70s.

[0061] Step 2. Prepare a pure metal transition layer: Introduce argon gas with a flow rate of 230 sccm into the vacuum chamber, control the pressure in the vacuum chamber to be about 0.4 Pa; turn on the pulse bias power supply, set the bias value to 80V, and the duty cycle to be 60%; turn on the medium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com