Fixed-point monitoring and maintenance device and method for gas extraction drilling hole stability

A gas extraction and maintenance device technology, applied in gas discharge, safety device, measurement, etc., can solve the problems of no drilling stability monitoring, time-consuming and labor-intensive, waste of materials, etc., to achieve the support method that is easy to operate and guarantees service time. , the effect of simple support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

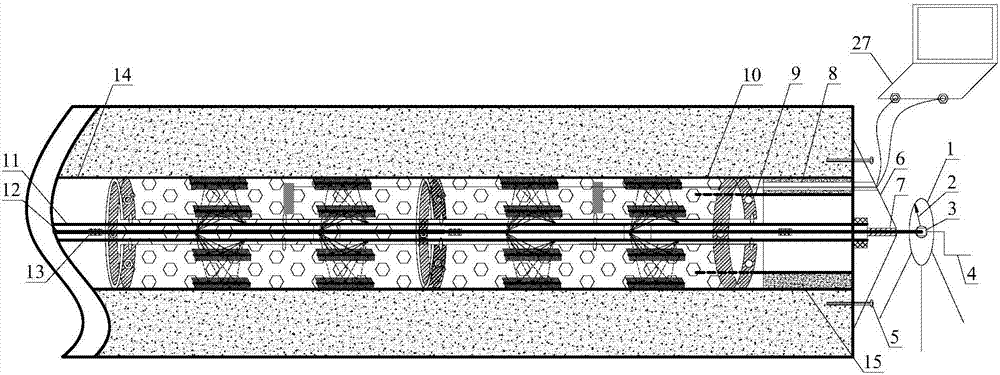

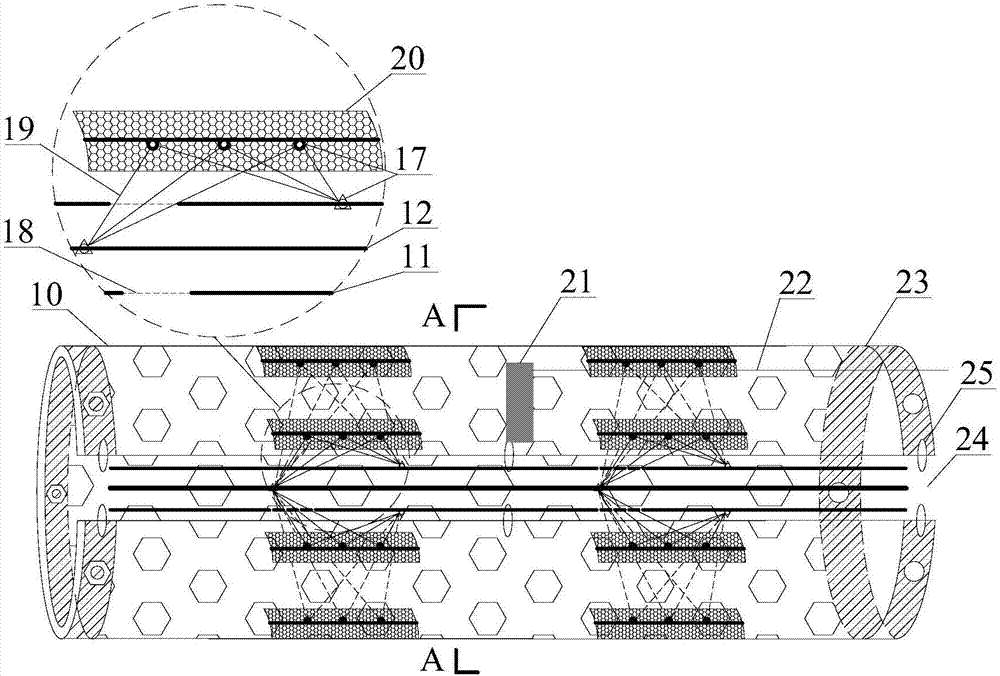

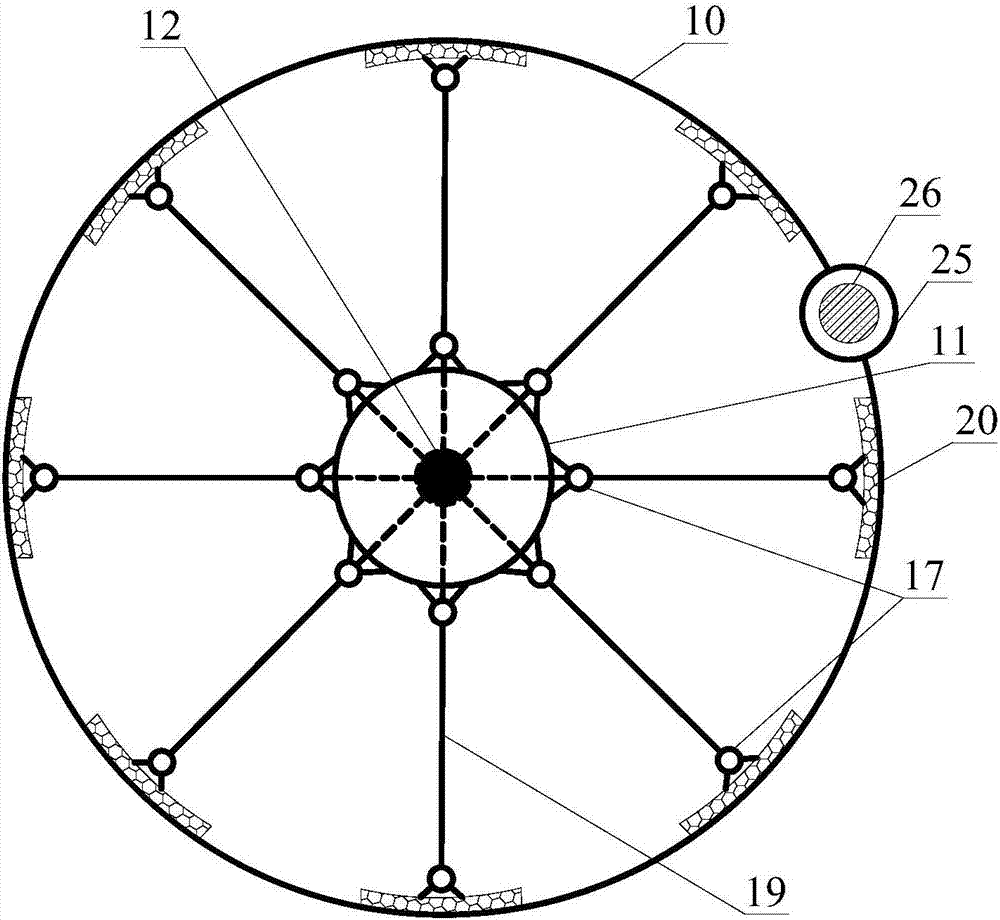

[0028] Such as Figure 1~4As shown, a fixed-point monitoring and maintenance device for gas drainage borehole stability, the device includes a borehole deformation monitoring system, a fixed-point support system, an end fixing device, and a supporting power application device; the borehole deformation monitoring system includes a load-bearing screen Pipe 10, strain gauge 21, wire 22, stress-strain monitor 27, strain gauge 21 is close to the inner wall of bearing screen pipe 10, and is connected with stress-strain monitor 27 through wire 22; The fixed-point support system includes transmission rod 12, Support shaft 11, strut rod 19, support touch plate 20, support touch plate is hingedly connected between strut bar 19 and transmission rod 12, support shaft 11; Described end fixing device is fixed on the coal wall of borehole 14, and transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com