A Fault Detection Method for Urban Rail Train Wheel Flat Scars

A technology for fault detection and urban rail trains, applied to measuring devices, measuring vibration, and vibration measurement in solids, etc., can solve problems such as reduced safety and riding comfort, enhanced interaction force, and damage, and achieves obvious detection results. The method has strong applicability and good real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

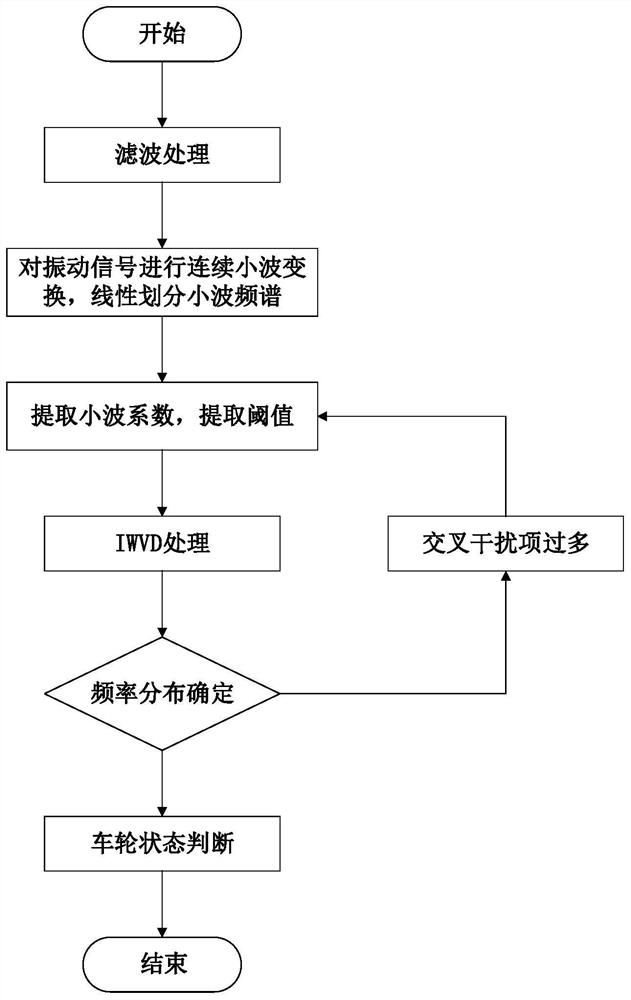

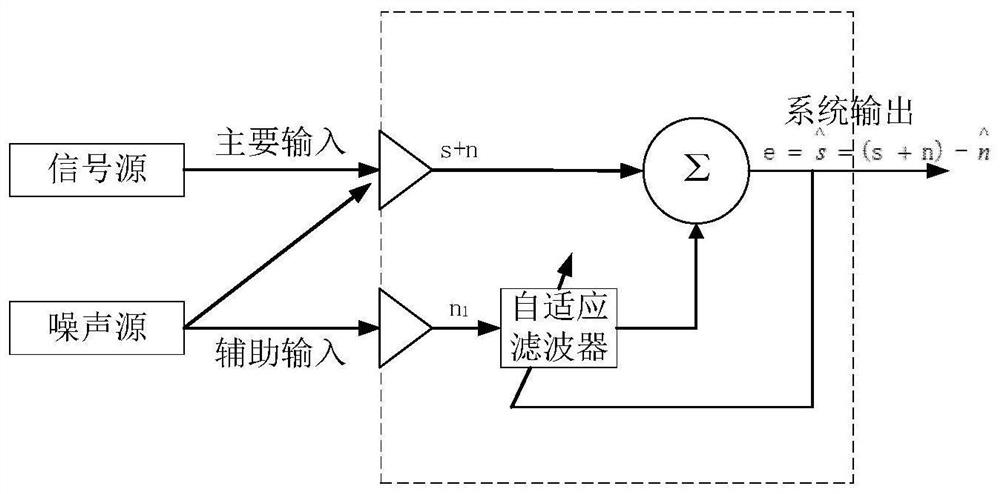

Method used

Image

Examples

Embodiment 1

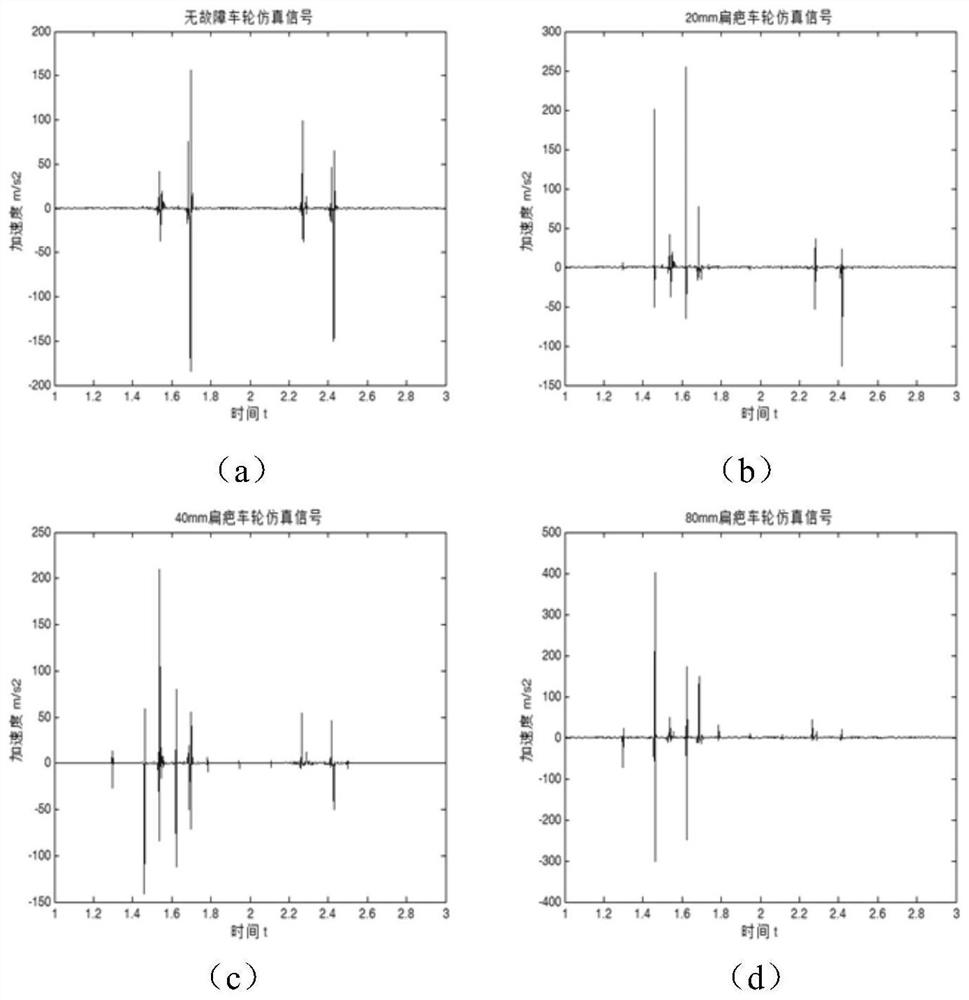

[0089] Apply the described IWVD time-frequency distribution analysis method, and use the simulation data obtained by the computer simulation model established by Simpack to carry out experiments: select the simulation signal and the speed of 60 kilometers per hour for the single-section carriage bogie fault-free wheel at a speed of 60 kilometers per hour The single wheel of No. 1 bogie of the single car per hour is processed with the simulation signals of 20mm, 40mm, and 80mm flat scars respectively. Its time domain diagram is as image 3 As shown, where (a) is the simulated signal diagram of a non-faulty wheel, (b) the simulated signal diagram of a 20mm flat-scarred wheel, (c) the simulated signal diagram of a 40mm flat-scarred wheel, and (d) the simulated signal diagram of an 80mm flat-scarred wheel. The time-frequency diagram of IWVD is as follows Figure 4 As shown, where (a) is the IWVD diagram of a non-faulty wheel, (b) is the IWVD diagram of a 20mm flat-scarred wheel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com